Selecting the right PTFE expansion joint is a critical engineering decision that goes far beyond matching a pipe's diameter. The choice hinges on a methodical evaluation of your system's operational parameters, including the pressure, temperature, chemical media, and the specific movements the joint must absorb to prevent catastrophic failure.

The core objective is not simply to find a part that fits, but to specify a component that guarantees the integrity, safety, and longevity of your entire piping system. A mismatch in any single factor can introduce a critical point of failure, leading to costly downtime and significant safety hazards.

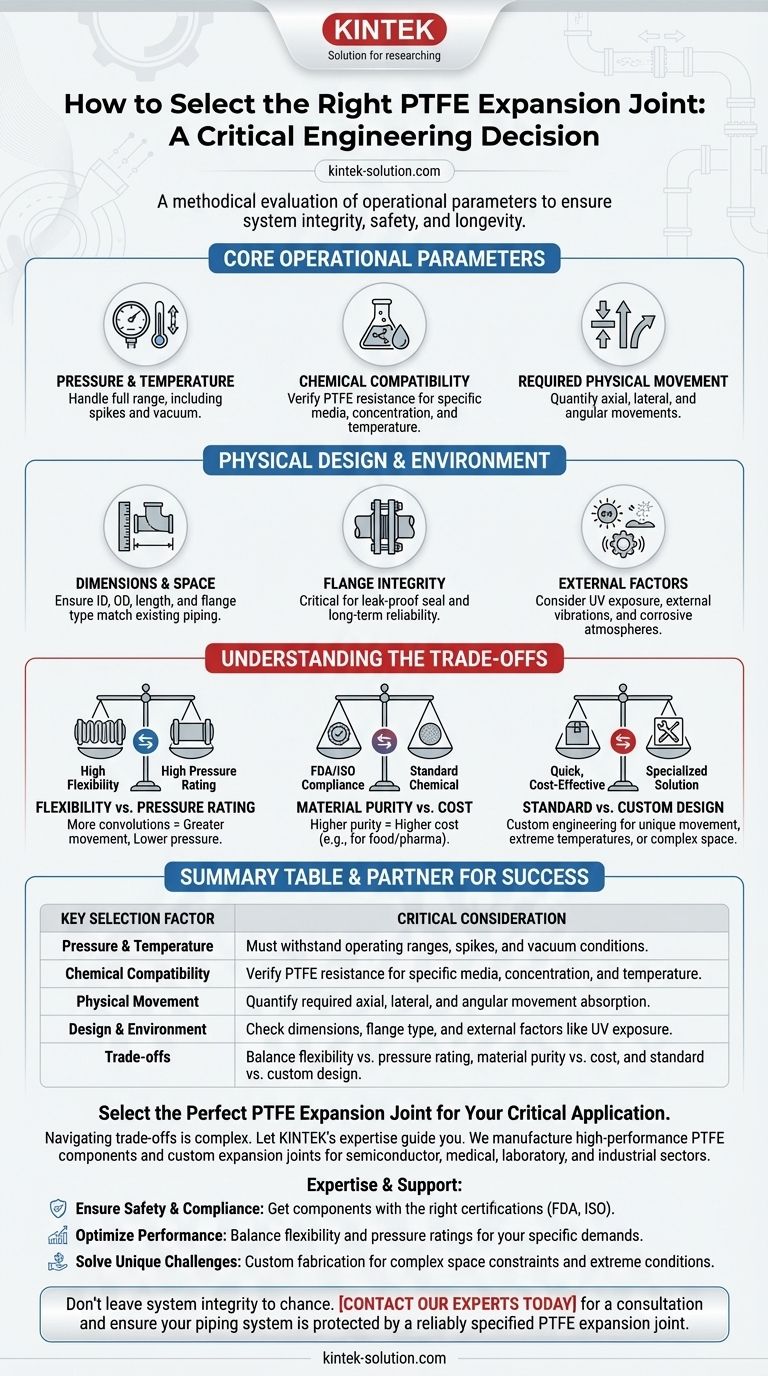

Core Operational Parameters

The performance of a PTFE expansion joint is dictated by its ability to withstand the fundamental forces within your system. These three factors are non-negotiable starting points for your analysis.

System Pressure and Temperature

The joint must be rated to handle the full range of your system's conditions. This includes not only the standard operating pressure and temperature but also any potential spikes, surges, or vacuum conditions that may occur.

Chemical Compatibility

While PTFE is known for its exceptional chemical resistance, you must verify its compatibility with the specific media flowing through your pipes. Consider the concentration and temperature of the substance, as these can affect material performance over time.

Required Physical Movement

Expansion joints are designed to absorb specific types of movement. You must quantify the required axial (compression/extension), lateral (offset), and angular (bending) movement your system will experience to select a joint with adequate flexibility.

Physical Design and Environment

Once the core parameters are defined, the joint's physical construction and its interaction with the surrounding environment become the next critical layer of consideration.

Dimensions and Installation Space

Ensure the joint's internal diameter (ID), external diameter (OD), and overall length are compatible with your existing piping and the physical space available for installation. Tighter spaces may require a more compact, specialized design.

Flange and Connection Integrity

The joint's connection points are vital for a leak-proof seal. The flange type must match your piping system, and the condition of the flange surfaces is critical for ensuring proper gasket seating and long-term reliability.

External Environmental Factors

Do not overlook the conditions outside the pipe. Factors like UV exposure from sunlight, external vibrations from nearby machinery, or exposure to corrosive atmospheres can degrade the joint's materials and shorten its service life.

Understanding the Trade-offs

Selecting an expansion joint is often a balancing act. Understanding the inherent design trade-offs is crucial for making an informed decision rather than simply choosing the highest-rated option.

Flexibility vs. Pressure Rating

A direct trade-off exists between a joint's ability to move and its ability to contain pressure. More convolutions provide greater flexibility and movement absorption but typically result in a lower pressure rating. Conversely, a thicker liner or fewer convolutions can handle higher pressures but will offer less movement.

Material Purity vs. Cost

Different applications require different grades of PTFE. A system in a food or pharmaceutical application requiring FDA compliance will necessitate a higher-purity, and therefore more expensive, material than a standard industrial chemical line.

Standard vs. Custom Design

Off-the-shelf expansion joints can meet the needs of many standard applications quickly and cost-effectively. However, for systems with unique movement requirements, extreme temperatures, or complex space constraints, a custom-engineered solution is often the only way to ensure safety and functionality.

Making the Right Choice for Your Goal

Partnering with a knowledgeable supplier who can provide consulting and engineering services is a critical step in mitigating risk. They can help you navigate these variables to ensure optimal selection.

- If your primary focus is managing high-pressure or high-temperature media: Prioritize the joint's pressure/temperature ratings and liner thickness, even if it means accepting lower movement capabilities.

- If your primary focus is absorbing complex multi-axial pipe movement: Concentrate on the number of convolutions and the manufacturer's specified data for axial, lateral, and angular movement.

- If your primary focus is safety and regulatory compliance: Verify all material certifications (e.g., FDA, ISO) and select a supplier who provides comprehensive engineering support and documentation.

A methodical approach to these factors ensures your expansion joint becomes a reliable asset, not a potential point of failure.

Summary Table:

| Key Selection Factor | Critical Consideration |

|---|---|

| Pressure & Temperature | Must withstand operating ranges, spikes, and vacuum conditions. |

| Chemical Compatibility | Verify PTFE resistance for specific media, concentration, and temperature. |

| Physical Movement | Quantify required axial, lateral, and angular movement absorption. |

| Design & Environment | Check dimensions, flange type, and external factors like UV exposure. |

| Trade-offs | Balance flexibility vs. pressure rating, material purity vs. cost, and standard vs. custom design. |

Select the Perfect PTFE Expansion Joint for Your Critical Application

Navigating the trade-offs between pressure, movement, and chemical resistance is complex. Let KINTEK's expertise guide you. We manufacture high-performance PTFE components, including custom expansion joints, for the semiconductor, medical, laboratory, and industrial sectors.

Our engineering team provides the consulting support you need to:

- Ensure Safety & Compliance: Get components with the right certifications (FDA, ISO) for your industry.

- Optimize Performance: We help you balance flexibility and pressure ratings for your specific system demands.

- Solve Unique Challenges: From prototypes to high-volume orders, we deliver custom fabrication for complex space constraints and extreme conditions.

Don't leave system integrity to chance. Contact our experts today for a consultation and ensure your piping system is protected by a reliably specified PTFE expansion joint.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts