In the medical field, PTFE energized seals are critical components used in a wide range of applications, including drug delivery systems, advanced surgical tools, diagnostic instrumentation, and pharmaceutical manufacturing equipment. Their unique properties make them suitable for both reusable, sterilizable devices and single-use disposable products where reliability and purity are paramount.

The core reason PTFE energized seals are so prevalent in medicine is not just their ability to seal, but their unique combination of chemical inertness, low friction, and resilience to extreme conditions. This triad of properties ensures device reliability, prevents contamination, and ultimately enhances patient safety.

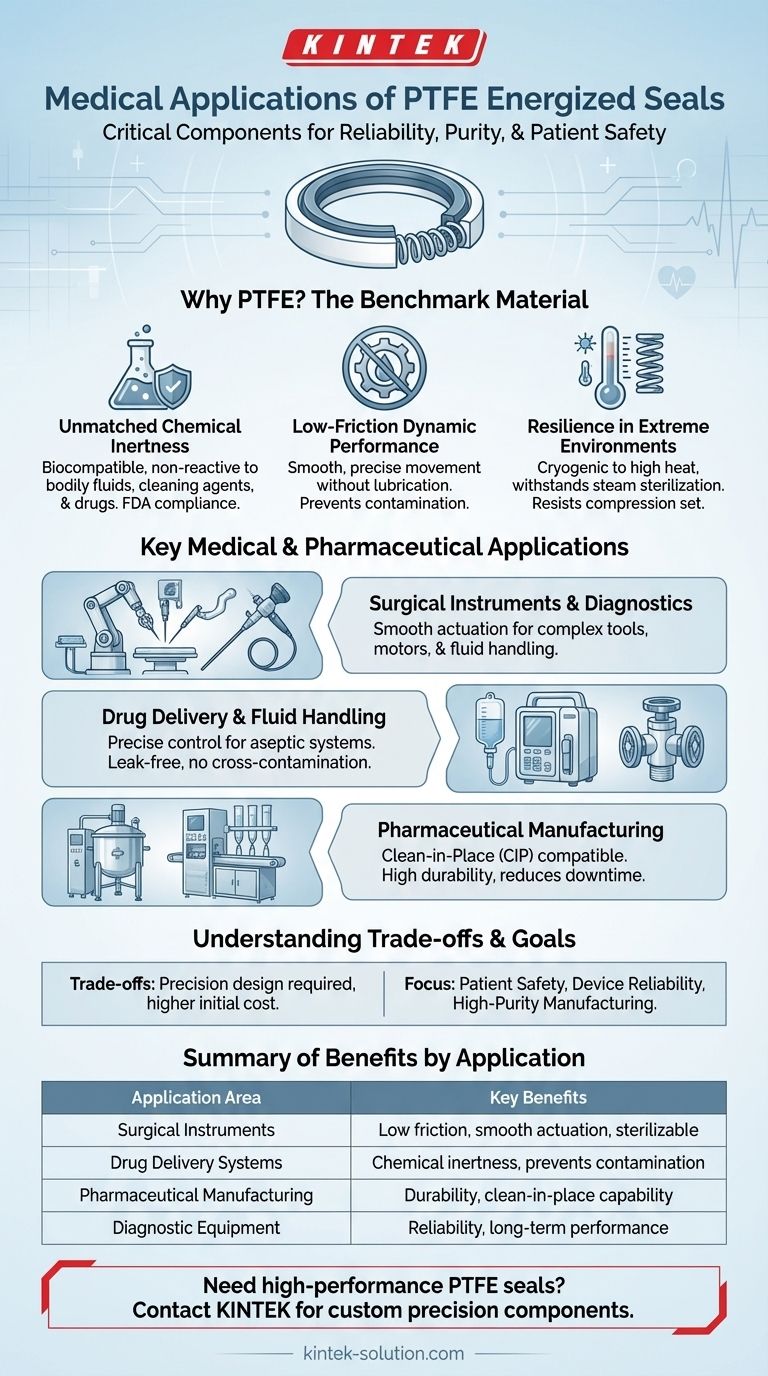

Why PTFE is a Benchmark Material for Medical Seals

The selection of a sealing material in a medical or pharmaceutical context goes far beyond simply preventing leaks. It involves ensuring biocompatibility, withstanding harsh sterilization processes, and maintaining performance over time.

Unmatched Chemical Inertness

PTFE is virtually inert, meaning it does not react with bodily fluids, aggressive cleaning agents, or the active ingredients in pharmaceutical products.

This property is critical for applications requiring FDA compliance and biocompatibility, as it ensures the seal will not degrade or leach harmful substances into the patient or the product.

Low-Friction Dynamic Performance

Many medical devices, from surgical instruments to drug delivery pumps, have moving parts. PTFE energized seals have an exceptionally low coefficient of friction.

This allows for smooth, precise, and repeatable movement without the need for lubrication, which could otherwise become a source of contamination.

Resilience in Extreme Environments

Medical applications often involve a wide range of operating conditions. PTFE seals function reliably across a vast temperature spectrum, from cryogenic storage of biological samples to the high heat of steam sterilization.

They also resist compression set, a common failure mode in elastomeric seals where the material permanently deforms and loses its sealing force. The internal spring ensures a consistent sealing pressure is always applied.

Key Medical and Pharmaceutical Applications

The unique properties of PTFE energized seals make them the solution of choice in several critical areas across the healthcare and life sciences industries.

Surgical and Diagnostic Instruments

Modern surgical tools, including robotic systems and endoscopic devices, rely on seals that provide smooth, reliable actuation. PTFE seals are used in motors, actuators, and fluid-handling components within these complex instruments.

Drug Delivery and Fluid Handling

In devices like infusion pumps, solenoid valves, and metering systems, precise control of fluids is essential. PTFE seals and bellows ensure leak-free operation and prevent cross-contamination in these aseptic systems.

Their inertness guarantees that the chemical composition of the drug being delivered remains unchanged.

Pharmaceutical Manufacturing

Equipment such as mixers, pumps, and filling systems are subject to rigorous cleaning and sterilization protocols. Spring-energized seals can be designed for Clean-in-Place (CIP) processes.

This durability reduces equipment downtime and maintenance costs while ensuring the highest levels of purity in the manufacturing line.

Understanding the Trade-offs

While highly effective, PTFE energized seals are a specialized solution. Understanding their context is key to proper application.

Design and Installation Precision

Unlike a simple O-ring, a spring-energized seal is a more complex component. Achieving optimal performance requires careful design of the hardware gland and attention to factors like surface finish. They are not always a simple drop-in replacement for other seal types.

Higher Initial Cost

The advanced materials and manufacturing processes used for PTFE energized seals typically result in a higher upfront cost compared to standard elastomeric seals. This cost, however, is often justified by reduced maintenance, lower risk of failure, and longer operational life.

Making the Right Choice for Your Goal

Selecting the correct seal depends entirely on the specific demands of the application.

- If your primary focus is patient safety and biocompatibility: PTFE's inertness is non-negotiable for any device with direct or indirect contact with fluids, tissues, or pharmaceutical agents.

- If your primary focus is device reliability and longevity: The seal's resistance to wear, compression set, and harsh sterilization ensures long-term performance in critical equipment where failure is not an option.

- If your primary focus is high-purity manufacturing: The combination of durability, chemical resistance, and clean-in-place capability makes these seals essential for preventing contamination in pharmaceutical production.

Ultimately, PTFE energized seals provide the high-performance reliability and material purity that modern medical technology demands.

Summary Table:

| Application Area | Key Benefits of PTFE Seals |

|---|---|

| Surgical Instruments | Low friction, smooth actuation, sterilizable |

| Drug Delivery Systems | Chemical inertness, prevents contamination |

| Pharmaceutical Manufacturing | Durability, clean-in-place capability |

| Diagnostic Equipment | Reliability, long-term performance |

Need high-performance PTFE seals for your medical or pharmaceutical application? At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication services, from prototypes to high-volume orders, ensure your devices meet the highest standards of reliability and purity. Contact us today to discuss your specific requirements and let our expertise enhance your product's safety and performance!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech