At its core, PTFE coating enhances corrosion resistance by creating a chemically inert and non-reactive physical barrier on the fastener. This shield physically isolates the underlying metal from corrosive agents such as moisture, salts, and harsh chemicals, effectively preventing the electrochemical reactions that cause rust and degradation.

The crucial insight is that PTFE is not just a simple layer of paint. It is a high-performance fluoropolymer that provides a robust, multi-faceted shield, combining near-universal chemical inertness with a low-friction surface for unparalleled protection and reliability in demanding environments.

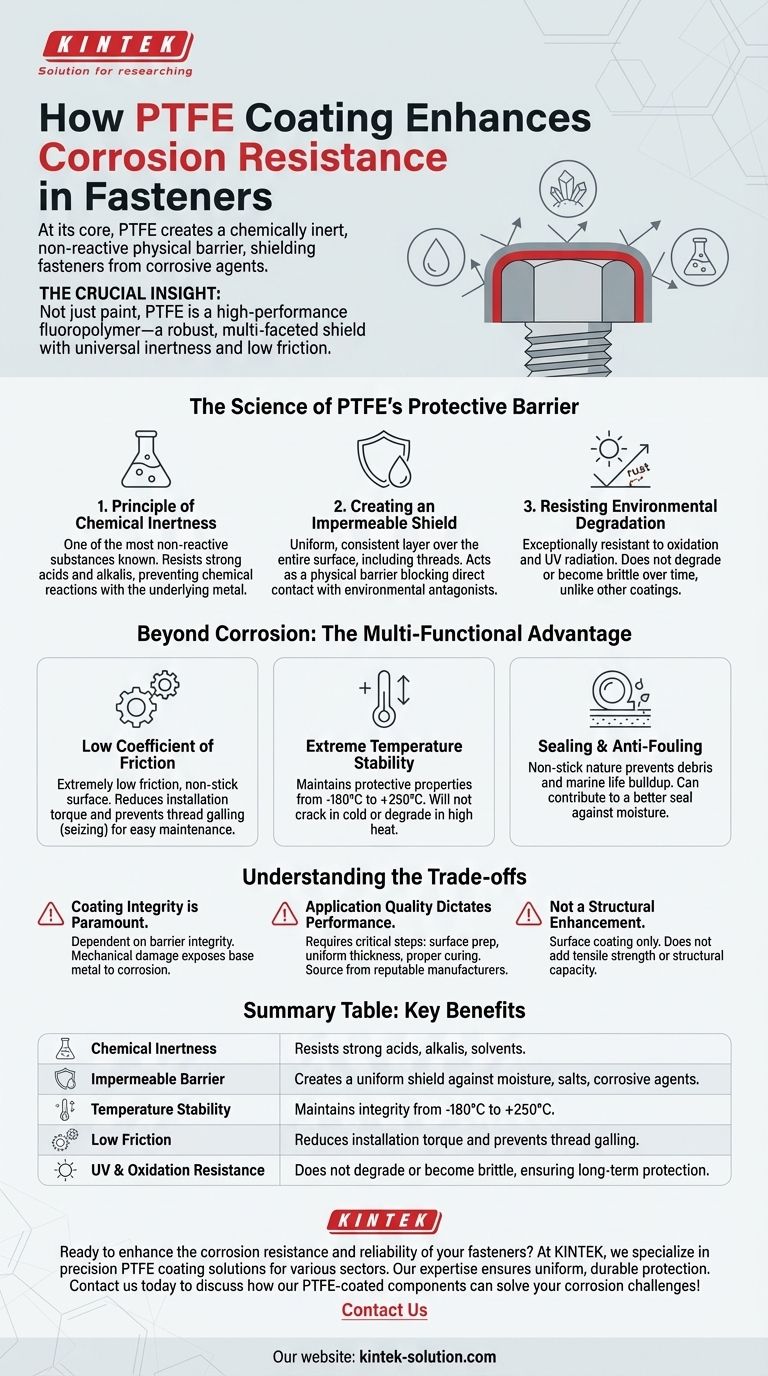

The Science of PTFE's Protective Barrier

To understand why PTFE is so effective, we need to look at its fundamental properties. Its ability to protect a fastener is not based on a single characteristic but on a combination of powerful molecular traits.

The Principle of Chemical Inertness

PTFE is one of the most non-reactive substances known. Its molecular structure makes it resistant to a vast range of chemicals, including strong acids and alkaline conditions.

This means that when corrosive fluids come into contact with the coating, no chemical reaction occurs, leaving the barrier and the underlying metal unharmed.

Creating an Impermeable Shield

The coating process is designed to create a uniform, consistent layer over the entire surface of the fastener, including the threads.

This layer acts as a physical barrier, preventing direct contact between the metal substrate and environmental antagonists like moisture and salt. Without this contact, the process of oxidation (rust) cannot begin.

Resisting Environmental Degradation

PTFE is exceptionally resistant to oxidation and UV radiation. It does not degrade, lose its plasticity, or become brittle when exposed to the elements over long periods.

This ensures the protective shield remains intact and effective throughout the fastener's service life, unlike other coatings that can break down over time.

Beyond Corrosion: The Multi-Functional Advantage

While corrosion resistance is the primary driver for using PTFE coatings, the material provides several other significant operational benefits that contribute to the overall integrity and reliability of a bolted connection.

Low Coefficient of Friction

PTFE has an extremely low coefficient of friction, making it a highly lubricious, non-stick surface. This dramatically reduces the torque required for installation and, more importantly, prevents thread galling (seizing).

This property ensures that fasteners can be removed easily for maintenance, even after years of service in a harsh environment.

Extreme Temperature Stability

The protective properties of PTFE are maintained across a vast temperature range, typically from -180°C to +250°C (-292°F to +482°F).

The coating will not crack in extreme cold or degrade in high heat, ensuring the protective barrier is never compromised by thermal cycling.

Sealing and Anti-Fouling

The non-stick nature of PTFE helps prevent the buildup of debris, marine life, or scale on the fastener. In some applications, the coating can also contribute to a better seal, further protecting the joint from moisture intrusion.

Understanding the Trade-offs

While highly effective, PTFE coatings are not without limitations. Acknowledging these trade-offs is key to using them correctly and avoiding potential failures.

Coating Integrity is Paramount

The protection offered by PTFE is entirely dependent on the integrity of the barrier. A deep scratch, gouge, or other mechanical damage that exposes the base metal creates a localized point for corrosion to begin.

Care must be taken during installation and handling to avoid compromising the coating.

Application Quality Dictates Performance

The effectiveness of the coating is directly tied to the quality of its application. This involves critical steps like surface preparation, uniform coating thickness, and proper thermal curing to bond the PTFE to the substrate.

An improperly applied coating can flake or peel, rendering it useless. Sourcing from a reputable manufacturer is essential to guarantee performance.

Not a Structural Enhancement

It is critical to remember that PTFE is a surface coating. It adds no tensile strength or structural capacity to the fastener itself. The choice of the underlying metal must still be appropriate for the mechanical loads of the application.

Making the Right Choice for Your Goal

Selecting the right fastener is about matching its properties to your most critical operational need.

- If your primary focus is longevity in marine or chemical plants: The near-universal chemical inertness of PTFE offers the most reliable long-term protection against salt spray and aggressive industrial chemicals.

- If your primary focus is ease of maintenance and assembly: The low-friction, anti-galling surface of PTFE ensures that fasteners can be reliably installed to the correct torque and, crucially, removed without damage years later.

- If your primary focus is reliability in fluctuating temperatures: PTFE's exceptional thermal stability ensures the protective coating remains intact and effective, unlike other materials that can become brittle or degrade with thermal swings.

Ultimately, specifying PTFE-coated fasteners is an investment in operational reliability, reducing future maintenance costs and preventing critical failures in your most demanding applications.

Summary Table:

| Key Benefit | Description |

|---|---|

| Chemical Inertness | Resists strong acids, alkalis, and solvents, preventing chemical reactions. |

| Impermeable Barrier | Creates a uniform shield to block moisture, salts, and corrosive agents. |

| Temperature Stability | Maintains integrity from -180°C to +250°C, unaffected by thermal cycling. |

| Low Friction | Reduces installation torque and prevents thread galling for easy maintenance. |

| UV & Oxidation Resistance | Does not degrade or become brittle over time, ensuring long-term protection. |

Ready to enhance the corrosion resistance and reliability of your fasteners?

At KINTEK, we specialize in precision PTFE coating solutions for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures a uniform, durable barrier that protects your components from the harshest environments, reducing maintenance costs and preventing failures.

We offer custom fabrication from prototypes to high-volume orders, tailored to your specific needs.

Contact us today to discuss how our PTFE-coated components can solve your corrosion challenges!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries