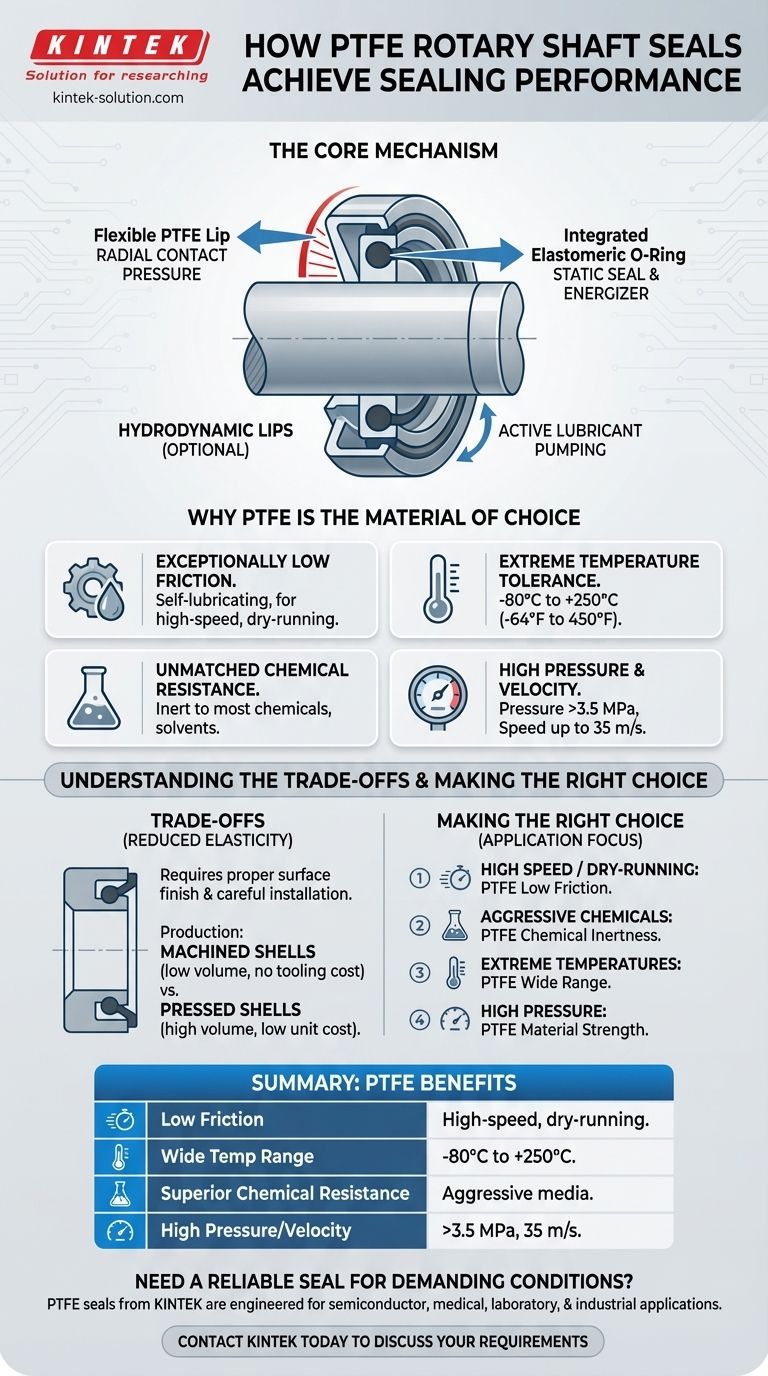

At its core, a PTFE rotary shaft seal works by combining a precisely engineered shape with the unique material properties of Polytetrafluoroethylene (PTFE). A specialized molding process creates a flexible lip that exerts a specific radial contact pressure against the rotating shaft, while an internal O-ring ensures a tight, static seal against the housing and energizes the lip.

The true effectiveness of a PTFE seal lies not just in the material itself, but in a dual-action design: mechanical pressure from the seal's shape creates the primary barrier, while the exceptional properties of PTFE allow this barrier to survive extreme speeds, temperatures, and chemicals.

How a PTFE Seal Creates a Barrier

The sealing mechanism is a deliberate two-part system. It relies on a mechanical design to create the force and a superior material to maintain it under demanding conditions.

The Sealing Lip and Radial Pressure

The primary sealing action comes from the PTFE lip. During manufacturing, this lip is shaped to have a slightly smaller diameter than the shaft it will seal.

When installed, this interference fit creates a consistent radial contact pressure around the shaft's circumference, forming the dynamic seal that prevents leakage.

The Role of the Integrated O-Ring

An elastomeric O-ring is almost always incorporated into the seal's design, but it sits on the static side of the seal, not the rotating surface.

This O-ring serves two critical functions:

- It creates a static seal between the outer diameter of the PTFE seal and the housing bore, preventing leaks along this path.

- It acts as an energizer, applying constant pressure to the back of the PTFE lip, ensuring it remains in tight contact with the shaft even with temperature fluctuations or minor wear.

Hydrodynamic Configurations

Advanced designs may feature hydrodynamic lips. These have microscopic features molded into the seal face that use the shaft's rotation to actively pump lubricant back towards the bearing, further enhancing sealing performance and reducing friction.

Why PTFE is the Material of Choice

Standard elastomeric (rubber) seals have limits. PTFE is chosen when application conditions exceed what conventional materials can handle.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This self-lubricating property is critical for high-speed applications.

This minimizes heat generation, reduces power loss, and allows the seal to function in dry-running or minimally lubricated conditions where a rubber seal would quickly overheat and fail. Some grades are even graphite-filled to further enhance these properties.

Extreme Temperature Tolerance

PTFE seals operate effectively across an incredibly wide temperature range, typically from -80°C to +250°C (-64°F to 450°F), with some capable of handling even greater extremes.

This makes them suitable for applications involving cryogenic fluids or high-temperature engines and machinery where traditional elastomers would become brittle or degrade.

Unmatched Chemical Resistance

PTFE is virtually inert and resistant to almost all industrial chemicals and solvents. This makes it the default choice for sealing in aggressive chemical processing, pharmaceutical, or food and beverage applications.

High Pressure and Velocity Capability

The material's rigidity and low-friction nature allow PTFE seals to perform where others cannot. They can withstand pressures exceeding 3.5 MPa (500 psi) and surface speeds up to 35 m/s.

Understanding the Trade-offs

While powerful, PTFE seals are not a universal solution. Understanding their limitations is key to successful implementation.

Reduced Elasticity

Compared to rubber, PTFE is a much more rigid material. It has less elasticity and cannot accommodate significant imperfections in shaft or housing surfaces.

Proper surface finish and careful, tool-assisted installation are critical to avoid damaging the sealing lip.

Production and Cost

The manufacturing method can impact cost. For high-volume production, seals are made with pressed shells, which reduces the unit cost but requires a significant upfront tooling investment.

For low-volume or custom sizes, seals can be made from machined shells. This avoids tooling charges but results in a higher cost per individual seal.

Making the Right Choice for Your Application

Selecting the right seal depends entirely on the specific demands of your operating environment.

- If your primary focus is high speed or dry-running capability: The extremely low friction and self-lubricating properties of PTFE are the deciding factors.

- If your primary focus is aggressive chemical exposure: PTFE's chemical inertness makes it the most reliable and often the only viable choice.

- If your primary focus is extreme hot or cold temperatures: The vast operating temperature range of a PTFE seal is unmatched by conventional elastomers.

- If your primary focus is high pressure: PTFE's material strength allows it to handle pressures that would extrude or destroy a standard rubber seal.

Ultimately, choosing a PTFE seal is a decision to prioritize performance and durability in conditions where other materials would fail.

Summary Table:

| Key Feature | Benefit |

|---|---|

| Low Friction PTFE | Enables high-speed operation and dry-running capability |

| Wide Temperature Range | Performs from -80°C to +250°C and beyond |

| Superior Chemical Resistance | Withstands aggressive chemicals and solvents |

| High Pressure/Velocity | Handles pressures >3.5 MPa and speeds up to 35 m/s |

Need a reliable seal for demanding conditions?

PTFE seals from KINTEK are engineered to solve your toughest sealing challenges in semiconductor, medical, laboratory, and industrial applications. Our precision manufacturing ensures optimal performance, and we offer custom fabrication from prototypes to high-volume orders.

Contact KINTEK today to discuss your specific requirements and get a seal built for extreme performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- How does molybdenum disulfide (MoS2) enhance PTFE? Boost Hardness, Wear Resistance & Durability

- How should PTFE material be supported during machining? Achieve Precision with Minimal Clamping Pressure

- What are the primary applications of extra-thick PTFE washers (5mm – 6mm)? Critical for High-Pressure Sealing & Load-Bearing

- What is unique about PTFE waffle seals and their applications? Superior Sealing with Built-In Contamination Control

- What industries benefit from using PTFE rotary seals? Solve Extreme Environment Challenges

- How are Teflon rods utilized in the chemical processing industry? For Seals, Liners & Valves That Resist Corrosion

- What are the key properties of PTFE pipes? Unlock Unmatched Chemical & Thermal Resistance

- What is the pH range that PTFE Enveloped Gaskets can handle? Achieve Universal Chemical Resistance