At its core, the non-stick property of a PTFE washer is critical because it prevents the component from bonding to adjacent surfaces under heat, pressure, or chemical exposure. This ensures parts can be easily disassembled for maintenance, reduces operational friction in moving systems, and maintains a clean, reliable seal over time.

The term "non-stick" goes beyond simple convenience. In an engineering context, it is a direct indicator of PTFE's fundamental characteristics: an extremely low coefficient of friction and chemical inertness, which together deliver reliable performance in demanding environments.

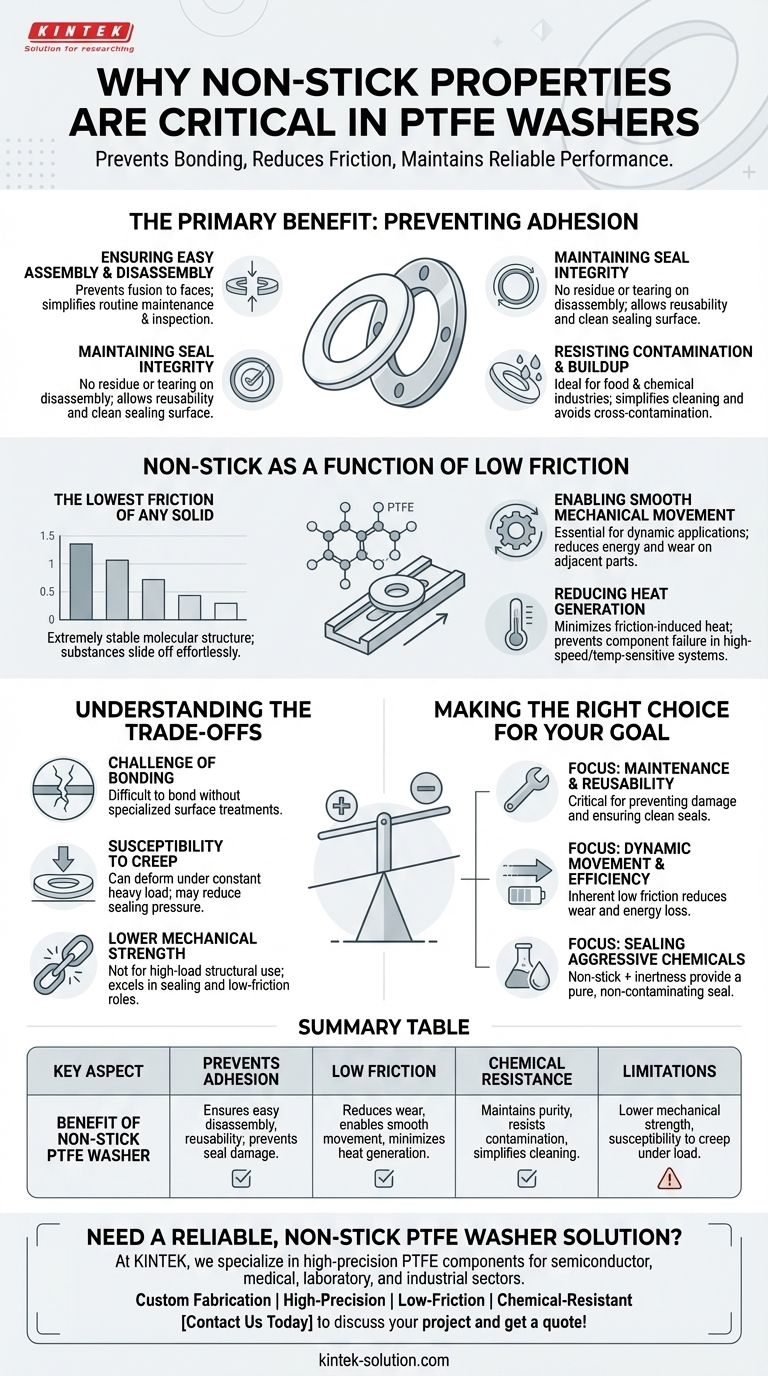

The Primary Benefit: Preventing Adhesion

The most direct advantage of a non-stick surface is its inability to adhere to other materials. This seemingly simple quality has profound implications for mechanical design and maintenance.

Ensuring Easy Assembly and Disassembly

In many assemblies, washers are subjected to significant compressive force. A PTFE washer’s non-stick nature ensures it will not fuse or "weld" to the flange or component faces, even after long periods of service. This is vital for any equipment that requires routine maintenance or inspection.

Maintaining Seal Integrity

When used as gaskets or seals, washers made of other materials can adhere to surfaces. During disassembly, this can cause the gasket to tear, leaving behind residue that must be scraped off and rendering the seal unusable. PTFE's non-stick quality prevents this, often allowing the washer to be reused and ensuring a clean sealing surface.

Resisting Contamination and Buildup

In industries like food processing or chemical manufacturing, material purity is essential. The non-stick surface of PTFE prevents process media from clinging to the washer, which simplifies cleaning and reduces the risk of cross-contamination between batches.

Non-Stick as a Function of Low Friction

The non-stick property is an outward expression of PTFE’s remarkably low coefficient of friction. This is not just a surface treatment; it is an inherent property of the material itself.

The Lowest Friction of Any Solid

PTFE (Polytetrafluoroethylene) has one of the lowest coefficients of friction of any known solid material. Its molecular structure is incredibly stable and non-reactive, which means other substances have nothing to latch onto, causing them to slide off effortlessly.

Enabling Smooth Mechanical Movement

In dynamic applications where parts rotate or slide against the washer, this low friction is paramount. It allows for smoother operation, reduces the energy required to move the components, and minimizes wear and tear on all adjacent parts.

Reducing Heat Generation

Friction creates heat. By minimizing friction, PTFE washers generate significantly less heat during operation. This is critical in temperature-sensitive applications or in high-speed systems where heat buildup could lead to component failure.

Understanding the Trade-offs

While its properties are highly beneficial, it's important to recognize the limitations that come with using PTFE.

The Challenge of Bonding

The same non-stick quality that makes PTFE an excellent sealant also makes it extremely difficult to bond to other materials using adhesives. Specialized surface treatments, like chemical etching, are often required to create a bondable surface.

Susceptibility to Creep

PTFE is a relatively soft material and can be susceptible to "creep" or "cold flow." This means that under a constant, heavy load, the washer may slowly deform over time, which can reduce sealing pressure in certain joint designs.

Lower Mechanical Strength

Compared to metal or harder engineering polymers, PTFE has lower compressive and tensile strength. It is not designed for high-load structural applications but excels in sealing and low-friction bearing roles.

Making the Right Choice for Your Goal

Ultimately, the importance of PTFE's non-stick property depends entirely on the demands of your application.

- If your primary focus is maintenance and reusability: The non-stick quality is critical for preventing damage during disassembly and ensuring clean sealing surfaces.

- If your primary focus is dynamic movement and efficiency: PTFE's inherent low friction, which creates the non-stick effect, is the key advantage for reducing wear and energy loss.

- If your primary focus is sealing aggressive chemicals: The non-stick surface works in tandem with PTFE's chemical inertness to provide a pure, non-contaminating, and reliable seal.

Understanding that the non-stick property is an integral part of PTFE's low-friction and non-reactive nature allows you to leverage it for superior performance and reliability.

Summary Table:

| Key Aspect | Benefit of Non-Stick PTFE Washer |

|---|---|

| Prevents Adhesion | Ensures easy disassembly and reusability, prevents seal damage. |

| Low Friction | Reduces wear, enables smooth movement, and minimizes heat generation. |

| Chemical Resistance | Maintains purity, resists contamination, and simplifies cleaning. |

| Limitations | Lower mechanical strength, susceptibility to creep under load. |

Need a reliable, non-stick PTFE washer solution for your application?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your components deliver the critical non-stick, low-friction, and chemical-resistant performance you require.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision to meet your exact specifications.

Contact us today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How does a pneumatic actuator function in a PTFE pneumatic valve? A Guide to Automated Control

- How do PTFE coatings prevent component failure? Control Friction and Corrosion for Reliable Performance

- What is FEP and how does it differ from PTFE? Key Differences in Performance & Manufacturing

- What are the overall advantages of using PTFE balls in fluid management systems? Enhance Reliability & Efficiency

- Why is PTFE used for gaskets? Superior Sealing for Harsh Chemical & Temperature Environments

- Why should traditional lubricants not be used with PTFE-lined bearings? Avoid Premature Failure and High Friction

- What considerations should be made when deciding to use PTFE gaskets? Balance Chemical Resistance with Mechanical Limits

- What are the primary applications of PTFE expansion bellows? Protect Piping Systems from Stress & Corrosion