In short, Polytetrafluoroethylene (PTFE) is used for gaskets because of its exceptional chemical resistance, wide temperature tolerance, and extremely low friction. These properties make it one of the most reliable sealing materials for demanding industrial applications where other elastomers or polymers would quickly degrade and fail.

PTFE is the material of choice when a sealing application involves aggressive chemicals or extreme temperatures. Its unique molecular structure makes it nearly impervious to chemical attack and functional from cryogenic conditions up to 260°C (500°F), ensuring a durable and reliable seal.

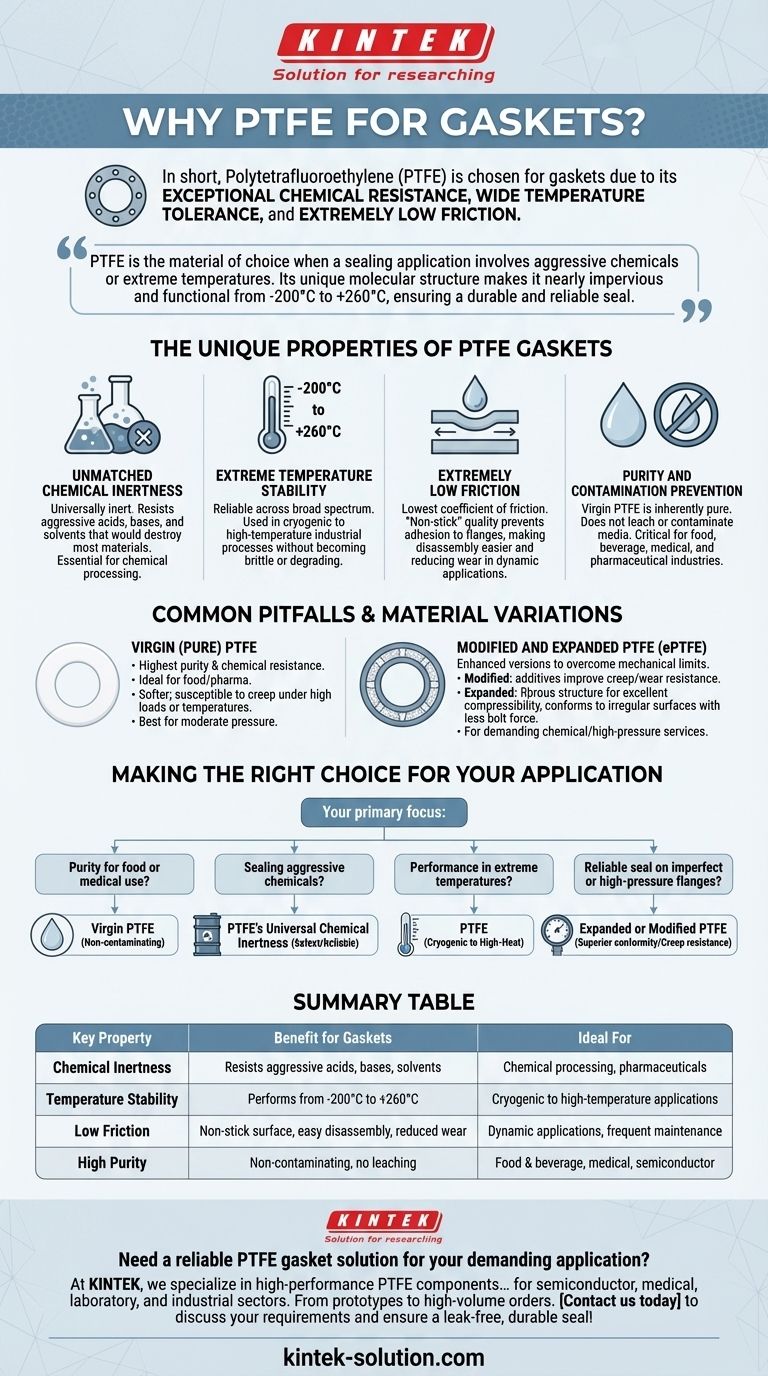

The Unique Properties of PTFE Gaskets

To understand why PTFE is so prevalent, we must examine its core characteristics. Its value lies in a combination of physical and chemical properties that are difficult to find in any other single material.

Unmatched Chemical Inertness

PTFE is a fluoropolymer, a plastic consisting of only carbon and fluorine atoms. This strong carbon-fluorine bond makes the material almost universally inert.

It is highly resistant to a vast range of chemicals, including aggressive acids, bases, and solvents that would destroy most other materials. This makes it an essential component in chemical processing.

Extreme Temperature Stability

PTFE gaskets perform reliably across an incredibly broad temperature spectrum. They maintain their integrity and mechanical strength in conditions ranging from -200°C to +260°C (-328°F to +500°F).

This thermal stability allows them to be used in everything from cryogenic applications to high-temperature industrial processes without becoming brittle or degrading.

Extremely Low Friction

Commonly known by the trade name Teflon, PTFE has one of the lowest coefficients of friction of any solid material. This "non-stick" quality is highly beneficial for gaskets.

It prevents the gasket from adhering to flange surfaces, making disassembly easier and cleaner. In dynamic applications with rotating or sliding parts, this low-friction surface reduces wear and extends service life.

Purity and Contamination Prevention

Virgin PTFE is an inherently pure material that does not leach or contaminate the media it contacts.

This non-contaminating property is critical in industries like food and beverage manufacturing, medical device production, and pharmaceuticals, where product purity is non-negotiable.

Common Pitfalls and Material Variations

While PTFE is a superior material, selecting the right type is critical. Using the wrong variation can lead to sealing issues, particularly with creep or cold flow—the tendency of a material to deform under sustained pressure.

Virgin (Pure) PTFE

This is the standard form of PTFE. It offers the highest level of chemical resistance and purity, making it ideal for the food and pharmaceutical industries.

However, pure PTFE is mechanically softer and more susceptible to creep, especially under high bolt loads or at elevated temperatures. It is best suited for moderate pressure applications.

Modified and Expanded PTFE

To overcome the mechanical limitations of virgin PTFE, manufacturers have developed enhanced versions.

Modified PTFE includes additives that improve its resistance to creep and wear. Expanded PTFE (ePTFE) has a fibrous, multidirectional structure that offers excellent compressibility and recovery, allowing it to conform to irregular surfaces and create a tight seal with less bolt force.

These advanced forms are often specified for more demanding chemical, high-pressure, or high-temperature services where a more robust seal is required.

Making the Right Choice for Your Application

Your final selection depends entirely on the specific demands of the sealing environment.

- If your primary focus is purity for food or medical use: Virgin PTFE is the correct choice due to its non-contaminating properties.

- If your primary focus is sealing aggressive chemicals: PTFE's universal chemical inertness makes it the safest and most reliable option.

- If your primary focus is performance in extreme temperatures: The wide functional temperature range of PTFE makes it suitable for both cryogenic and high-heat applications.

- If your primary focus is a reliable seal on imperfect or high-pressure flanges: An expanded or modified PTFE gasket will provide superior conformity and resistance to creep.

Ultimately, choosing PTFE for a gasket is a strategic decision for ensuring long-term reliability in harsh operating conditions.

Summary Table:

| Key Property | Benefit for Gaskets | Ideal For |

|---|---|---|

| Chemical Inertness | Resists aggressive acids, bases, and solvents | Chemical processing, pharmaceuticals |

| Temperature Stability | Performs from -200°C to +260°C | Cryogenic to high-temperature applications |

| Low Friction | Non-stick surface, easy disassembly, reduced wear | Dynamic applications, frequent maintenance |

| High Purity | Non-contaminating, no leaching | Food & beverage, medical, semiconductor |

Need a reliable PTFE gasket solution for your demanding application?

At KINTEK, we specialize in manufacturing high-performance PTFE components—including seals, gaskets, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require the purity of virgin PTFE for sensitive processes or the enhanced performance of modified/expanded PTFE for high-pressure environments, we deliver precision-engineered solutions from prototypes to high-volume orders.

Contact us today to discuss your specific requirements and ensure a leak-free, durable seal!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments