PTFE coatings prevent component failure by creating a stable, low-friction, and chemically inert barrier. This dual-action protection ensures that fasteners, like bolts and nuts, achieve the correct tension during assembly and are shielded from corrosive elements during their service life. This is especially critical in systems subject to vibration or harsh environmental exposure.

The primary role of a PTFE coating is not to make a component stronger, but to control the two biggest sources of unpredictable mechanical failure: uncontrolled friction and environmental degradation. By managing these factors, it ensures components behave predictably and reliably under stress.

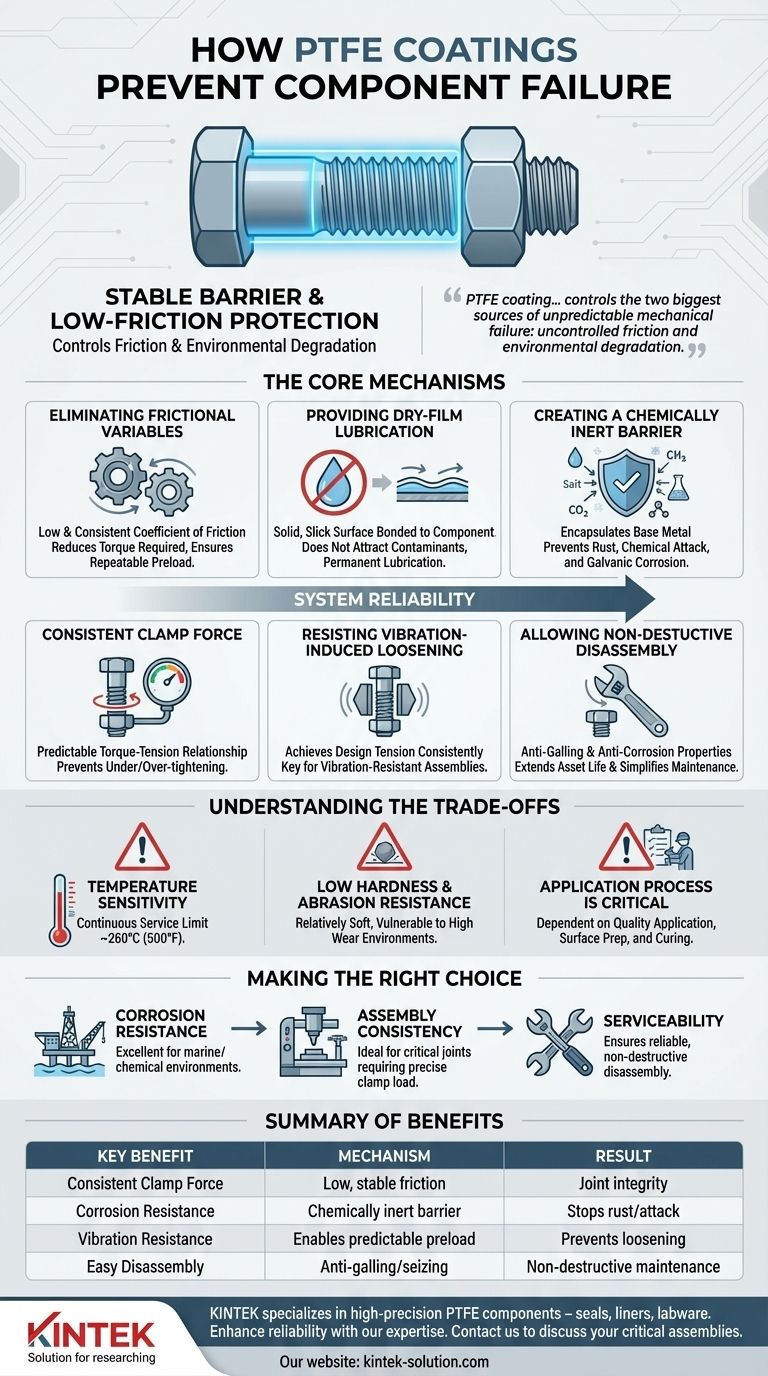

The Core Mechanisms of PTFE Protection

To understand how PTFE coatings improve reliability, we must first look at the fundamental problems they solve at a microscopic level. The failure of a component often begins with inconsistent assembly or slow environmental decay.

Eliminating Frictional Variables

Friction between the threads of a nut and bolt is the single greatest variable during assembly. An unlubricated fastener can expend up to 90% of the applied torque just overcoming friction, leaving only 10% for useful stretching of the bolt (the "preload" or "clamp force").

PTFE coatings have an extremely low and consistent coefficient of friction. This dramatically reduces the torque required to achieve a specific preload, ensuring that the force holding your assembly together is accurate and repeatable every single time.

Providing Dry-Film Lubrication

Unlike wet lubricants like grease or oil, PTFE is a dry-film lubricant. This means it is a solid, slick surface bonded directly to the component.

This is a critical distinction. Dry films do not attract and hold dirt, dust, or other contaminants that can alter friction and introduce abrasive particles into a joint. The lubrication is permanent and cannot be washed away.

Creating a Chemically Inert Barrier

PTFE is one of the most non-reactive substances known. The coating completely encapsulates the component's base metal (typically steel).

This barrier prevents moisture, salt, and industrial chemicals from ever reaching the substrate, effectively stopping rust and other forms of corrosion before they can begin. This also prevents galvanic corrosion, which can occur when dissimilar metals are in contact.

How This Translates to System Reliability

Controlling friction and corrosion has a direct and profound impact on the long-term integrity of any mechanical system.

Ensuring Consistent Clamp Force

The ultimate goal of tightening a fastener is to achieve the correct clamp force. This force is what holds a joint together and allows it to resist external loads.

By stabilizing the friction, PTFE coatings make the relationship between applied torque and resulting clamp force predictable. This prevents both under-tightening (which leads to loosening) and over-tightening (which can damage the fastener or component).

Resisting Vibration-Induced Loosening

A properly tensioned fastener is highly resistant to loosening from vibration. The tension creates a significant frictional force under the bolt head and in the threads that prevents it from rotating backward.

Because PTFE ensures this design tension is met consistently, it is a key strategy in building vibration-resistant assemblies.

Allowing for Non-Destructive Disassembly

A common failure point occurs during maintenance. Corroded or galled (cold-welded) fasteners often have to be cut off, damaging the component and increasing downtime.

PTFE's anti-corrosion and anti-galling properties ensure that components can be easily disassembled, inspected, and reassembled without damage, significantly extending the life of the asset.

Understanding the Trade-offs

While highly effective, PTFE coatings are not a universal solution. Understanding their limitations is key to using them successfully.

Temperature Sensitivity

Standard PTFE has a continuous service temperature limit of around 260°C (500°F). For applications exceeding this, other coating solutions must be considered.

Low Hardness and Abrasion Resistance

PTFE is a relatively soft material. In environments with high levels of abrasive grit or direct mechanical wear, the coating can be scratched or eroded, compromising its protective barrier.

Application Process is Critical

The performance of a PTFE coating is entirely dependent on the quality of its application. This requires meticulous surface preparation, precise application, and proper curing. A poorly applied coating will offer little to no benefit and may flake off, creating new problems.

Making the Right Choice for Your Application

Selecting the right strategy requires aligning the coating's strengths with your primary engineering goal.

- If your primary focus is corrosion resistance: PTFE is an excellent choice for creating a chemically inert barrier, especially in marine, offshore, or chemical processing environments.

- If your primary focus is assembly consistency: The low, stable coefficient of friction makes PTFE ideal for critical bolted joints where achieving a precise clamp load is essential for safety and performance.

- If your primary focus is serviceability: PTFE's anti-galling and anti-corrosion properties ensure reliable and non-destructive disassembly for maintenance and inspection cycles.

Ultimately, leveraging a PTFE coating is a strategic decision to control variables, ensuring your components perform as designed from the day of assembly through their entire service life.

Summary Table:

| Key Benefit | Mechanism | Result |

|---|---|---|

| Consistent Clamp Force | Low, stable coefficient of friction | Prevents under/over-tightening, ensures joint integrity |

| Corrosion Resistance | Chemically inert barrier seals the substrate | Stops rust, chemical attack, and galvanic corrosion |

| Vibration Resistance | Enables predictable, high preload | Prevents loosening in dynamic environments |

| Easy Disassembly | Anti-galling and anti-seizing properties | Allows for non-destructive maintenance and reassembly |

Ensure your components perform reliably under stress. PTFE coatings are a strategic solution for controlling the variables that lead to unpredictable failure. KINTEK specializes in manufacturing high-precision PTFE components—including custom-coated seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume production, our expertise ensures your components are protected from friction and corrosion. Contact our team today to discuss how we can enhance the reliability of your critical assemblies.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- Why are PTFE heat press sheets essential for custom printing? Achieve Flawless, Professional Results

- What are mechanical seals with PTFE sealing rings? High-Performance Seals for Extreme Conditions

- What is the disadvantage of using glass as a filler in PTFE? The Critical Trade-off for Wear Resistance

- What environmental conditions were studied for PTFE sliding rubber bearing corrosion? Simulate Decades of Harsh Exposure

- What makes PTFE an excellent choice for gaskets, rings, and bearings? Unlock Unmatched Reliability with KINTEK PTFE

- What are the properties and uses of bronze-filled PTFE? A Guide to High-Performance Mechanical Components

- What are the limitations of machining Teflon? Overcoming Burrs, Creep, and Thermal Instability

- What are the characteristics of Modified PTFE with Premium Organic Fill? Superior Wear Resistance Without Abrasion