At its core, a traditional lubricant sabotages the very mechanism that makes a PTFE-lined bearing effective. Using oil, grease, or even some corrosion inhibitors on these components is a critical error. These substances create a physical barrier that prevents the self-lubricating PTFE liner from transferring onto the mating surface, which paradoxically leads to higher friction and drastically accelerated wear.

The fundamental mistake is treating a self-lubricating system as if it needs external help. PTFE-lined bearings are designed to run dry; adding a lubricant blocks their intended function and ultimately causes them to fail faster.

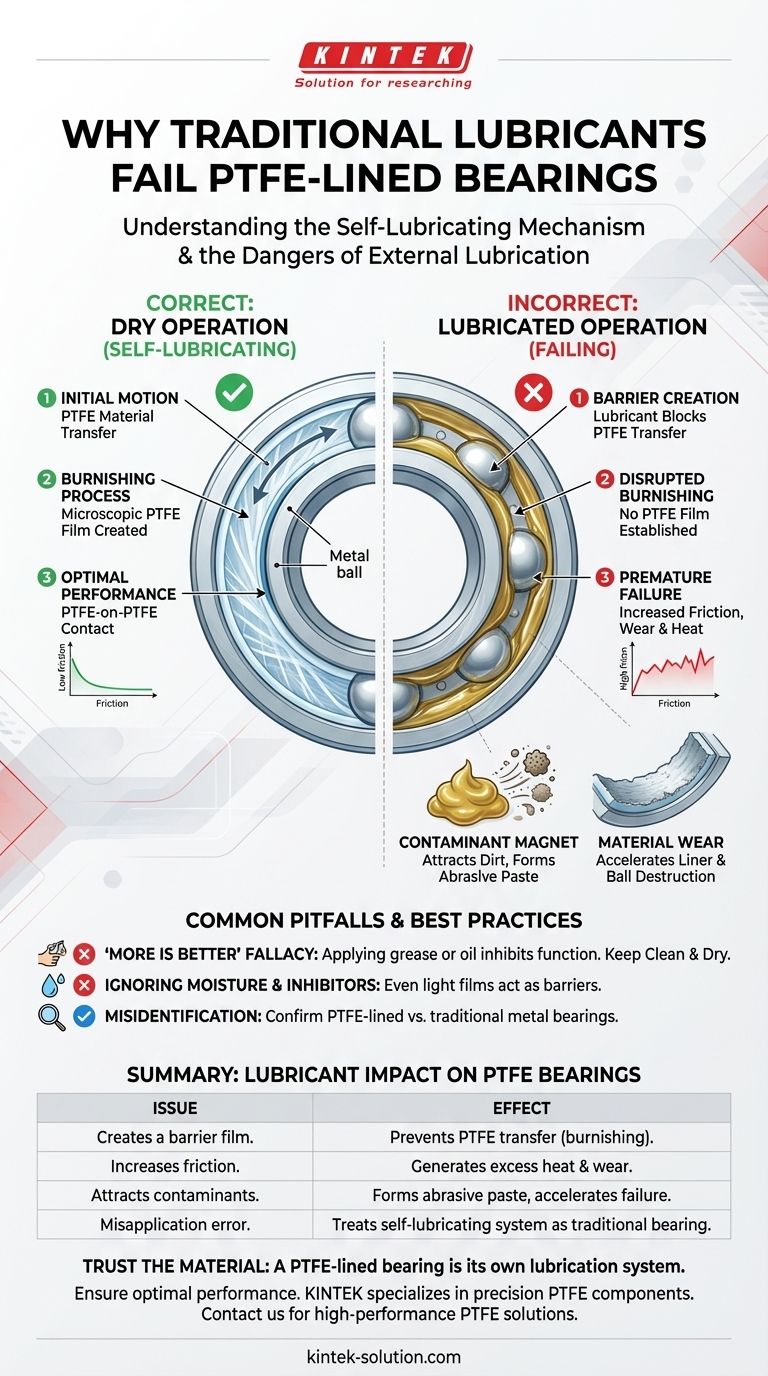

The Self-Lubricating Mechanism of PTFE Liners

To understand why adding lubricant is detrimental, we must first understand how these bearings are designed to function. They operate on a principle entirely different from traditional metal-on-metal bearings.

The Principle of "Transfer Lubrication"

PTFE (polytetrafluoroethylene) is an extremely low-friction material. In these bearings, the PTFE liner isn't just a surface—it is the lubricant.

The entire system is designed around the controlled transfer of this material to create an ideal sliding surface.

The Critical "Burnishing" Process

During the initial cycles of motion, a microscopic layer of the PTFE liner material physically transfers and bonds to the mating surface of the ball or shaft. This process is often called burnishing.

This transfer film is essential for proper performance. It effectively coats the metal surface with a layer of PTFE.

The Result: PTFE-on-PTFE Contact

Once the burnishing process is complete, the bearing operates with the PTFE liner sliding against the transferred PTFE film on the ball.

This PTFE-on-PTFE interface is what creates the extremely low friction and smooth operation characteristic of these components.

How External Lubricants Disrupt Performance

Introducing an external substance like oil or grease fundamentally disrupts the burnishing process and degrades the bearing's performance.

Creating a Barrier to Transfer

Oil and grease create a fluid film between the liner and the ball. This film acts as a barrier, physically preventing the liner from making the contact necessary to transfer its material.

Without this transfer, the low-friction PTFE-on-PTFE interface can never be established. The bearing is forced to operate in a way it was not designed for.

Increasing Friction and Wear

By blocking the burnishing process, the bearing operates at a much higher coefficient of friction.

This increased friction generates more heat and causes the liner to wear away rapidly, leading to premature failure of the component. The very lubricant intended to help instead causes damage.

Attracting Damaging Contaminants

Unlike dry-running PTFE, wet lubricants like grease are magnets for dust, dirt, and other environmental debris.

These contaminants can become embedded in the soft liner, creating an abrasive paste that grinds away at both the liner and the ball, accelerating destruction.

Common Pitfalls to Avoid

The instinct to lubricate a moving part is strong, but in this case, it's a critical mistake. Understanding these common pitfalls is key to ensuring reliability.

The "More is Better" Fallacy

The most common error is applying grease or oil out of habit, assuming it will protect the bearing. With PTFE liners, the opposite is true. The bearing must be kept clean and dry.

Ignoring Moisture and Inhibitors

Even light moisture or spray-on corrosion inhibitors can form a film that hinders the PTFE transfer process. Any substance that creates a barrier between the liner and the ball is a potential problem.

Misidentifying the Bearing Type

It is crucial to confirm that you are working with a self-lubricating, PTFE-lined bearing. A traditional metal bearing without a liner requires grease and will fail quickly without it. Misidentification leads to improper maintenance and failure.

Making the Right Maintenance Decision

Your goal is to allow the bearing to function exactly as its engineers designed it to.

- If your primary focus is maximum bearing life and low friction: Always install and operate the PTFE-lined bearing completely clean and dry.

- If you suspect a bearing was previously lubricated by mistake: Thoroughly clean the component with a manufacturer-approved solvent to remove all residue and allow it to dry completely before returning to service.

Trust the material's inherent properties; a PTFE-lined bearing is its own lubrication system.

Summary Table:

| Issue with Traditional Lubricants | Effect on PTFE-Lined Bearing |

|---|---|

| Creates a barrier film | Prevents PTFE transfer (burnishing) |

| Increases friction | Generates excess heat and wear |

| Attracts contaminants | Forms abrasive paste, accelerates failure |

| Misapplication error | Treats self-lubricating system as traditional bearing |

Ensure optimal performance and longevity for your PTFE-lined bearings. KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and labware—for semiconductor, medical, laboratory, and industrial applications. Our custom fabrication services, from prototypes to high-volume orders, guarantee that your equipment operates as designed.

Contact us today (#ContactForm) to discuss your specific needs and benefit from our expertise in high-performance PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech