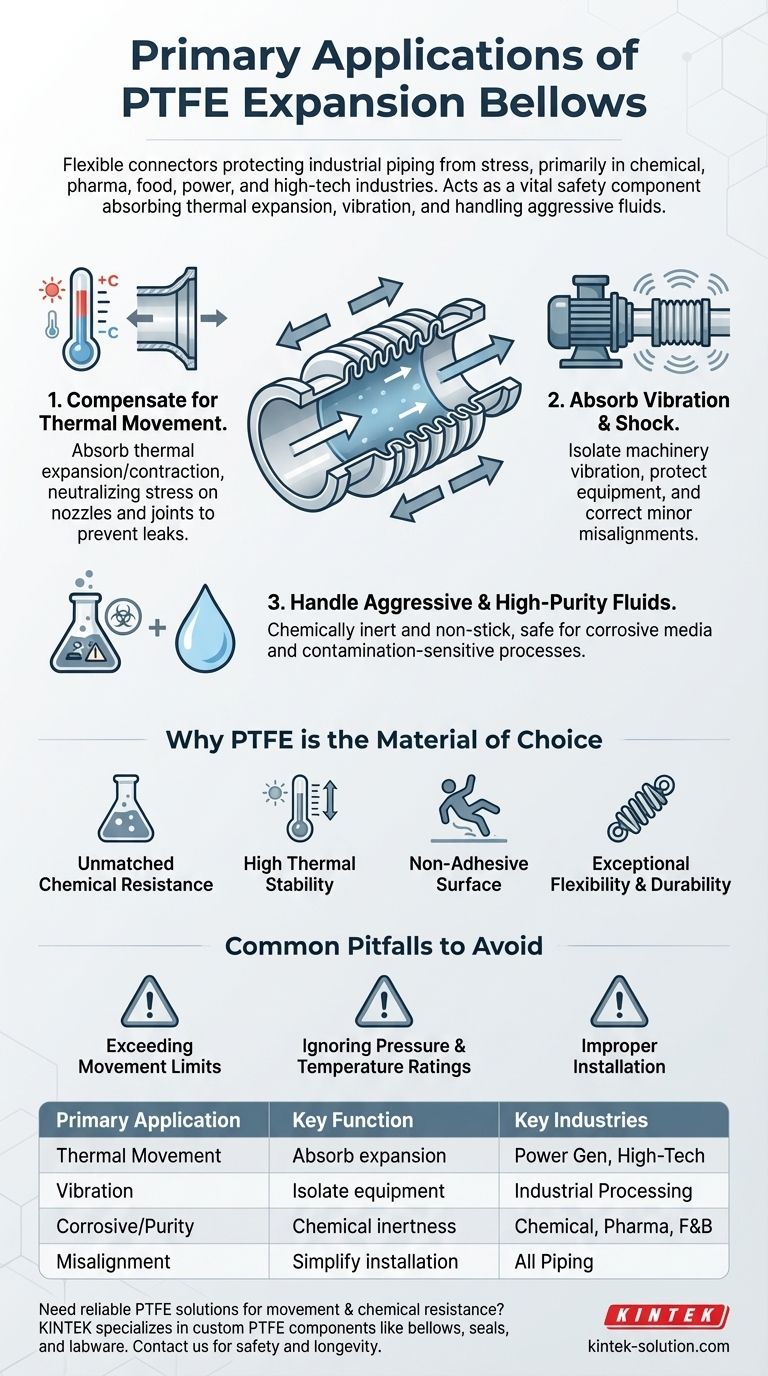

At their core, PTFE expansion bellows are flexible connectors used to protect industrial and commercial piping systems from stress. They are primarily applied in demanding industries like chemical processing, pharmaceuticals, food and beverage, power generation, and high-tech manufacturing where systems must handle aggressive chemicals, extreme temperatures, and mechanical vibration.

The crucial function of a PTFE expansion bellow is not just to connect pipes, but to act as a vital safety and maintenance component. It absorbs damaging forces—like thermal expansion, contraction, and vibration—that would otherwise lead to system failure, especially in environments where material purity and chemical resistance are non-negotiable.

The Core Problem: Managing Movement and Stress in Piping

Industrial piping is not static. It is a dynamic system subject to constant stress from temperature fluctuations, mechanical vibration, and slight misalignments. PTFE bellows are engineered to solve these fundamental problems.

Compensating for Thermal Expansion and Contraction

Piping systems expand when heated and contract when cooled. This movement creates immense stress on fixed points like nozzles, valves, and joints, which can lead to cracks and leaks.

PTFE bellows are designed to compress and extend, safely absorbing this thermal movement and neutralizing the stress on the overall system.

Absorbing Vibration and Misalignment

Pumps, compressors, and other machinery generate constant vibration. Over time, this mechanical shock can fatigue pipe welds and damage sensitive equipment connected to the line.

The flexibility of a bellow allows it to act as a shock absorber, isolating vibrations and preventing them from propagating through the pipeline. They also correct for minor initial pipe misalignment, simplifying installation.

Handling Aggressive and High-Purity Fluids

In many industries, the fluid itself is a major challenge. Highly corrosive chemicals can degrade metal components, while high-purity applications cannot tolerate any contamination from the piping material.

PTFE is nearly chemically inert and has a non-stick surface, ensuring it can safely transport aggressive fluids without corroding or leaching contaminants into the process media.

Why PTFE is the Material of Choice

The unique combination of properties inherent to Polytetrafluoroethylene (PTFE) makes it the ideal material for these demanding applications where others would quickly fail.

Unmatched Chemical Resistance

PTFE is resistant to nearly all industrial chemicals, acids, and solvents. This makes it the default choice for chemical processing and pharmaceutical manufacturing, where material integrity is paramount.

High Thermal Stability

These bellows can operate effectively across a very wide temperature range. This stability is critical in power generation, aerospace, and semiconductor manufacturing, where processes involve extreme heat or cold.

Non-Adhesive Surface

PTFE has one of the lowest coefficients of friction of any solid, creating a non-stick surface. This prevents material buildup and blockages, which is essential for ensuring efficient flow and easy cleaning in food, beverage, and pharmaceutical lines.

Exceptional Flexibility and Durability

Despite its robustness, PTFE is highly flexible. This allows the bellow to endure millions of cycles of compression and extension without fatiguing, ensuring a long and reliable service life.

Common Pitfalls to Avoid

While highly effective, the performance of PTFE bellows depends on correct application and installation. Overlooking these details can lead to premature failure.

Exceeding Movement Limits

Every bellow is rated for a maximum amount of axial (compression/extension) and lateral (sideways) movement. Stretching or compressing a bellow beyond its design limits will cause extreme stress and rapid failure.

Ignoring Pressure and Temperature Ratings

PTFE's mechanical strength can decrease at higher temperatures. It is critical to operate within the manufacturer's specified pressure and temperature ratings to prevent a rupture or catastrophic failure.

Improper Installation

Misalignment beyond the bellow's rated capacity, failure to use control rods in high-pressure systems, or torsion (twisting) during installation can place unintended stress on the component, leading to a drastically reduced lifespan.

Making the Right Choice for Your Goal

Selecting the correct component is about matching its capabilities to your primary operational challenge.

- If your primary focus is handling highly corrosive chemicals: The exceptional chemical inertness of PTFE makes it the safest and most reliable choice to prevent leaks and system degradation.

- If your primary focus is ensuring product purity: The non-adhesive and non-leaching properties of PTFE are critical for pharmaceutical and food-grade applications to avoid contamination.

- If your primary focus is protecting sensitive equipment: A PTFE bellow's ability to absorb vibration and shock is essential for isolating pumps, meters, and other machinery from pipeline stress.

Ultimately, integrating PTFE expansion bellows is a strategic decision to enhance the safety, longevity, and efficiency of your critical piping systems.

Summary Table:

| Primary Application | Key Function of PTFE Bellows | Key Industries Served |

|---|---|---|

| Compensate for Thermal Movement | Absorb expansion/contraction from temperature changes | Power Generation, High-Tech Manufacturing |

| Absorb Vibration & Shock | Isolate pumps/compressors, protect sensitive equipment | Industrial Processing, Manufacturing |

| Handle Corrosive & High-Purity Fluids | Provide chemical inertness & non-contaminating surface | Chemical Processing, Pharmaceuticals, Food & Beverage |

| Correct Minor Misalignments | Simplify installation and reduce stress on pipes | All Industrial Piping Systems |

Need a reliable, high-performance solution for your piping system's movement and chemical resistance challenges?

KINTEK specializes in the precision manufacturing of custom PTFE components, including expansion bellows, seals, liners, and labware. We serve demanding industries like semiconductor, medical, and laboratory, where material integrity is critical.

We partner with you from prototype to high-volume production to ensure your components meet exact specifications for durability, chemical resistance, and performance.

Contact KINTEK today to discuss your application and receive a quote for a custom PTFE solution that enhances your system's safety and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability