For harsh environments, spiral PTFE backup rings are the superior choice. Their seamless, continuous construction provides maximum resistance against O-ring extrusion under the high pressures, extreme temperatures, and aggressive chemical conditions that define demanding applications.

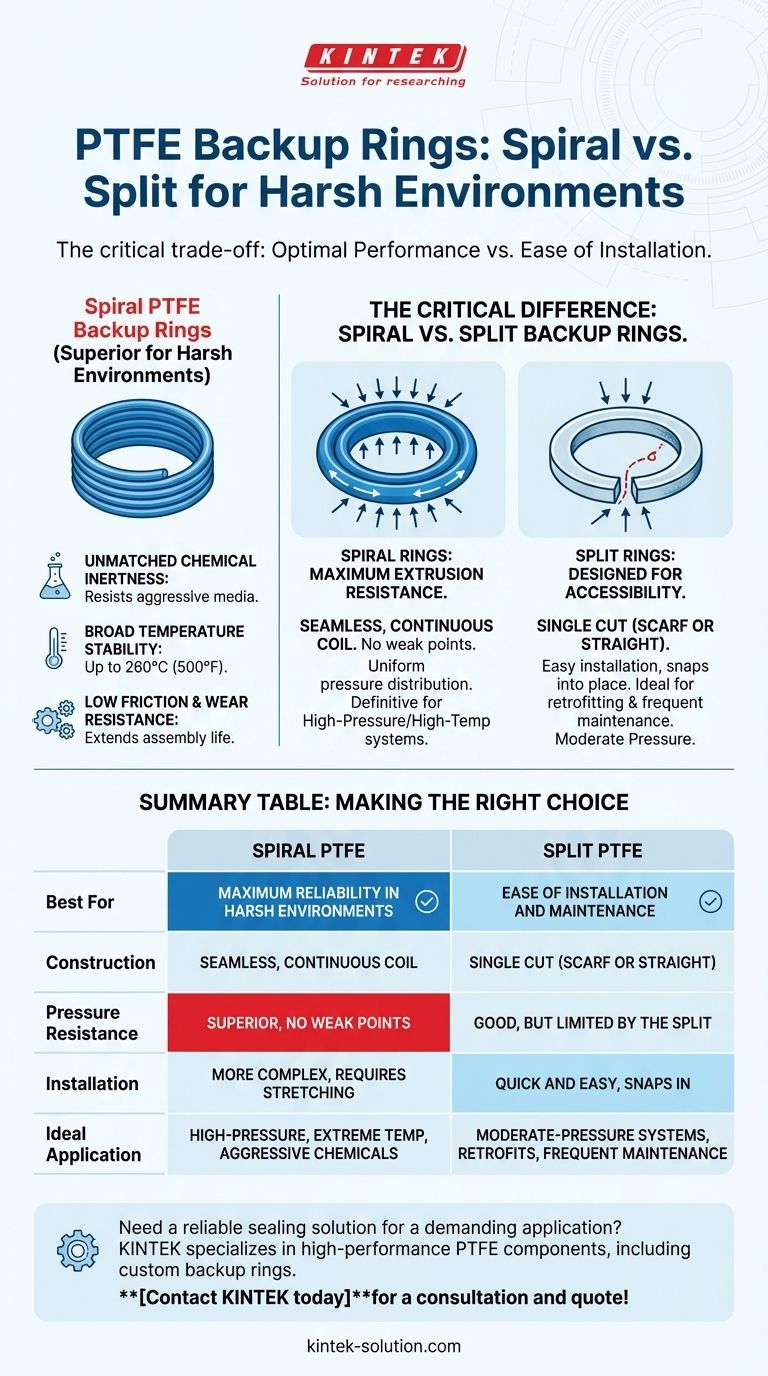

The decision between PTFE backup ring types hinges on a single trade-off: optimal performance versus ease of installation. While all PTFE rings leverage the material's inherent resilience, their physical form dictates their suitability for a specific operational challenge.

Why PTFE Excels in Harsh Environments

Before comparing ring types, it's essential to understand why Polytetrafluoroethylene (PTFE) is the material of choice for demanding seals. Its molecular structure gives it a unique combination of properties that other materials cannot match.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals and corrosive substances. This makes it an essential material for seals in chemical processing, oil and gas, and pharmaceutical industries where exposure to aggressive media is constant.

Broad Temperature Stability

PTFE components remain stable and functional across an exceptionally wide temperature range, often up to 260°C (500°F). This thermal stability ensures the seal's integrity is not compromised by extreme heat, a common condition in heavy machinery and processing pipelines.

Low Friction and Wear Resistance

PTFE has one of the lowest coefficients of friction of any solid material. This property minimizes wear and tear on both the seal and the surrounding hardware, extending the operational life of the entire assembly and reducing maintenance needs.

The Critical Difference: Spiral vs. Split Backup Rings

While the material is constant, the geometry of the backup ring is what truly defines its performance under pressure. The primary function of a backup ring is to prevent the softer O-ring from extruding into the clearance gap between hardware components.

Spiral Rings: Engineered for Maximum Extrusion Resistance

Spiral PTFE backup rings are manufactured as a continuous, uncut coil. This solid, seamless design provides a uniform and robust barrier against the O-ring.

Under high pressure, the force is distributed evenly around the spiral ring. There are no gaps or weak points where the O-ring could be forced through, making it the definitive choice for high-pressure and high-temperature systems where seal failure is not an option.

Split Rings: Designed for Accessibility

Split PTFE backup rings feature a single cut at an angle (a "scarf cut") or straight across. This design has one primary advantage: ease of installation.

The ring can be twisted open and snapped into a groove without needing to disassemble the entire component. This makes it ideal for retrofitting existing systems or for applications where frequent maintenance and quick assembly are prioritized over ultimate pressure resistance.

Understanding the Trade-offs

Choosing the right component requires an objective look at the limitations of each design. The ideal choice for one application may be a point of failure in another.

The Installation Challenge of Spiral Rings

The continuous nature of a spiral ring means it must be stretched over the hardware to be installed. This can be more time-consuming and requires careful handling to avoid damaging the ring or the component.

The Pressure Limitation of Split Rings

The cut in a split ring, while convenient for installation, creates a potential leak and extrusion path. Under very high pressure, the softer O-ring material can be forced into this small gap, leading to premature seal failure.

The Focus on Robust Construction

Ultimately, the term "harsh environment" implies high stakes and extreme conditions. The "robust construction" of a spiral ring directly addresses this by eliminating the inherent weak point—the split—found in other designs.

Making the Right Choice for Your Application

Your final decision should be guided by the single most critical priority of your system's design.

- If your primary focus is maximum reliability in high-pressure, high-temperature, or chemically aggressive systems: The seamless design of a spiral PTFE backup ring provides the best defense against seal extrusion.

- If your primary focus is ease of maintenance, rapid installation, or retrofitting existing equipment: A split PTFE backup ring offers unmatched convenience and is a practical choice for moderate-pressure applications.

By aligning the component's design with your system's operational demands, you ensure long-term reliability and performance.

Summary Table:

| Feature | Spiral PTFE Backup Ring | Split PTFE Backup Ring |

|---|---|---|

| Best For | Maximum reliability in harsh environments | Ease of installation and maintenance |

| Construction | Seamless, continuous coil | Single cut (scarf or straight) |

| Pressure Resistance | Superior, no weak points | Good, but limited by the split |

| Installation | More complex, requires stretching | Quick and easy, can be snapped in |

| Ideal Application | High-pressure systems, extreme temperatures, aggressive chemicals | Moderate-pressure systems, retrofits, frequent maintenance |

Need a reliable sealing solution for a demanding application?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom spiral and split backup rings, for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures your seals withstand extreme pressures, temperatures, and chemicals.

Let us provide the right PTFE solution for your specific needs, from prototypes to high-volume orders.

Contact KINTEK today for a consultation and quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why are PTFE spring-energized seals ideal for semiconductor manufacturing? Ensure Purity and Maximize Yield

- What makes molded PTFE sheet a cost-effective option? Reduce Long-Term Costs with Superior Durability

- What are the properties of stainless steel-filled PTFE balls? A Guide to Enhanced Strength & Performance

- What are the best practices for installing Teflon gland packing? Ensure a Reliable, Long-Lasting Seal

- Why does the spring PTFE sealing ring maintain effective sealing across its working pressure range? Discover the Engineering Secret

- How does the PTFE oil seal's design handle shaft eccentricity? Achieve Reliable Sealing Under Dynamic Conditions

- What are the disadvantages of unreinforced PTFE laminates? Navigating Manufacturing Challenges for High-Frequency Performance

- What environmental benefits do PTFE expansion joints provide? Achieve Sustainability and Compliance