At its core, the spring-energized PTFE sealing ring maintains effective sealing because its total contact stress is engineered to always exceed the pressure of the fluid it contains. This force comes from two sources: the initial mechanical force from the internal spring and the additional force generated by the system's own fluid pressure acting upon the seal itself. This dual-action mechanism ensures a tight seal from zero pressure up to its maximum working range.

The design's key principle is its adaptability. A mechanical spring provides a constant sealing force at low or zero pressure, while the system's own fluid pressure is harnessed to amplify that sealing force as operating pressure increases.

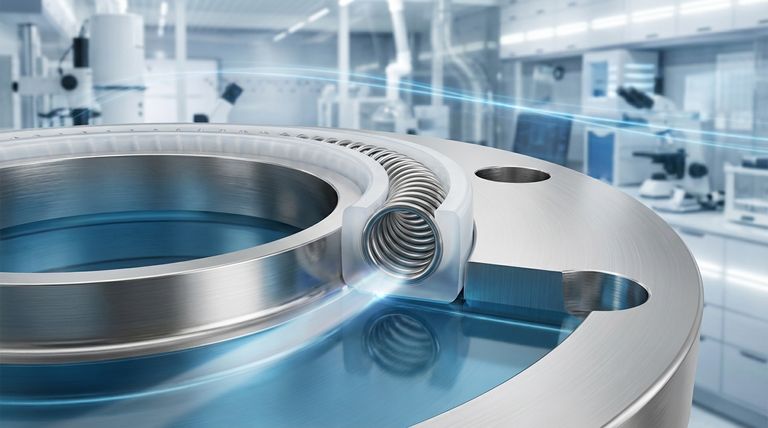

The Anatomy of a High-Performance Seal

To understand its performance, we must first look at its two critical components: the PTFE jacket and the metal spring energizer. Each plays a distinct and vital role.

The PTFE Jacket: The Sealing Surface

The outer part of the seal is a precisely machined jacket made of Polytetrafluoroethylene (PTFE). This material is chosen for its exceptional properties.

PTFE provides extremely high chemical resistance, a very low coefficient of friction, and the ability to operate across a vast temperature range, from -200°C to +260°C.

The Spring Energizer: The Source of Resilience

Inside the PTFE jacket sits a metal spring. This spring is the engine that provides the initial and continuous mechanical force for the seal.

Unlike seals made from rubber or other elastomers, which rely on material memory, this metal spring provides a more consistent and reliable force over the entire life of the seal, resisting compression set and material degradation.

The Physics of Sealing: A Two-Stage Process

The seal's effectiveness across a wide pressure range is due to a dynamic, two-stage sealing process that adapts to system conditions.

Stage 1: Initial Sealing at Low Pressure

When the seal is installed, the spring is compressed, generating a pre-tightening force.

This force pushes the flexible lips of the PTFE jacket outwards, creating a light but effective seal against the hardware surfaces even before any system pressure is applied.

Stage 2: Pressure-Assisted Sealing at High Pressure

As system pressure increases, the fluid enters the cavity of the seal. This pressure acts on the inner surfaces of the PTFE jacket.

The fluid pressure works in tandem with the spring, dramatically increasing the load on the sealing lips. The higher the system pressure, the stronger the sealing force becomes, ensuring the contact stress always remains greater than the pressure of the fluid being sealed.

From Line to Surface Contact

Under pressure, the resilient PTFE material also exhibits slight creep and elastic sliding.

This causes the seal to press firmly against the groove walls, transforming the initial "line contact" of the seal lips into a broader surface contact. This increases the sealing footprint and further improves its reliability.

Understanding the Trade-offs and Advantages

The design of a spring-energized seal provides distinct benefits over traditional elastomeric seals, but it's important to understand where it excels.

Consistent Long-Term Sealing Force

The primary advantage is the metal spring, which does not fatigue or degrade like rubber. This provides a much more consistent sealing force over time, especially in static applications or after long periods of inactivity.

Unmatched Environmental Resistance

The use of PTFE allows these seals to function in environments with aggressive chemicals or extreme temperatures that would cause standard seals to fail almost immediately.

Low-Friction Operation

PTFE's low coefficient of friction reduces wear on both the seal and the hardware. This is critical in dynamic applications to ensure smooth operation and prevent the "stick-slip" phenomenon common with other seal types.

Making the Right Choice for Your Goal

Selecting this seal is a matter of matching its unique capabilities to your application's demands.

- If your primary focus is reliability across a wide pressure range: This seal's ability to use system pressure to its own advantage makes it the ideal choice for dynamic systems.

- If your primary focus is resistance to harsh environments: The material properties of PTFE make it one of the only viable options for applications involving aggressive chemicals or extreme temperatures.

- If your primary focus is low friction and long life: The combination of a durable spring and low-friction PTFE ensures minimal drag and extended service life in dynamic sealing applications.

Ultimately, the spring-energized PTFE seal is a highly engineered solution that provides robust performance by intelligently adapting to the pressure it is designed to contain.

Summary Table:

| Feature | Key Component | Function |

|---|---|---|

| Sealing Surface | PTFE Jacket | Provides chemical resistance, low friction, and high-temperature stability. |

| Sealing Force | Metal Spring Energizer | Supplies consistent initial force and resists compression set for long-term reliability. |

| Sealing Mechanism | Two-Stage Process | Combines spring pre-load and system pressure to ensure contact stress always exceeds fluid pressure. |

Need a reliable sealing solution for demanding applications?

KINTEK specializes in manufacturing high-performance PTFE components, including custom spring-energized seals, for the semiconductor, medical, laboratory, and industrial sectors. Our precision engineering ensures your seals deliver consistent performance across extreme pressures, temperatures, and harsh chemical environments.

Contact us today to discuss your custom fabrication needs, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What makes PTFE coatings non-stick? The Science Behind the Ultimate Slippery Surface

- What are the applications of PTFE in the chemical industry? A Guide to Superior Corrosion Resistance

- What are the durability benefits of PTFE washers? Achieve Unmatched Chemical & Thermal Resistance

- What is the first step in both PTFE production methods? Unlocking the Key to High-Performance Polymer Manufacturing

- What are the key advantages of PTFE O-rings? Superior Chemical & Thermal Resistance

- Why should negative pressure be avoided with PTFE lined butterfly valves? Prevent Catastrophic Liner Failure

- How does PTFE perform in chemical resistance applications? Unmatched Inertness for Harsh Environments

- How do PTFE lined butterfly valves provide protection against chemicals and rust? Achieve Superior Corrosion Resistance