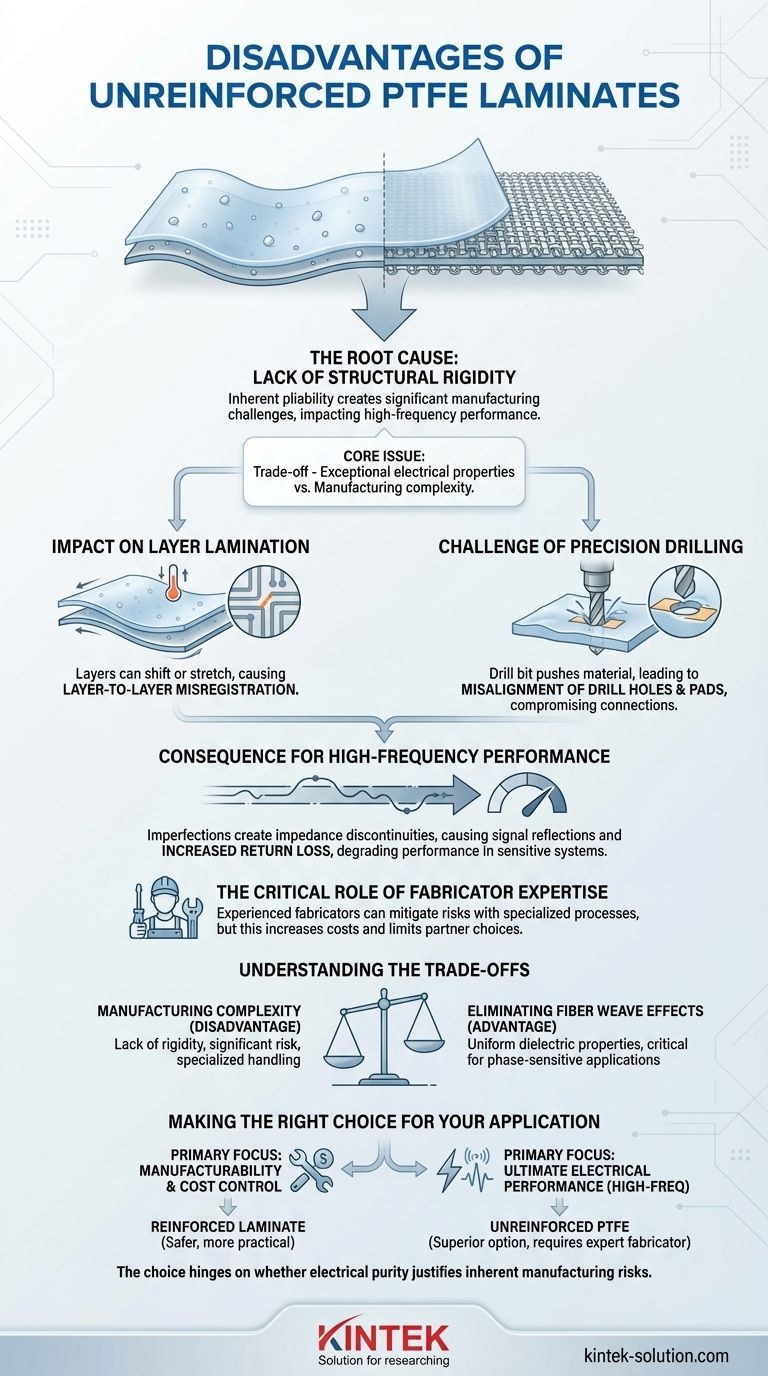

The primary disadvantage of unreinforced PTFE laminates is their lack of mechanical rigidity before the circuit board is fully cured. This inherent pliability creates significant challenges during the manufacturing process, which can directly impact the final product's high-frequency performance.

The core issue with unreinforced PTFE is a trade-off: its exceptional electrical properties for high-frequency applications come at the cost of manufacturing complexity. The material's softness can lead to physical inaccuracies during fabrication, demanding specialized handling to avoid performance degradation.

The Root Cause: Lack of Structural Rigidity

Unreinforced Polytetrafluoroethylene (PTFE) laminates are, by definition, missing the internal glass fiber weave that provides structural stability in reinforced materials. While often filled with ceramic particles to achieve specific dielectric properties, their fundamental nature is soft and pliable.

The Impact on Layer Lamination

During the multi-layer board fabrication process, heat and pressure are applied to bond the layers together.

Because unreinforced PTFE is so pliable, the individual layers can easily shift or stretch. This leads to layer-to-layer misregistration, where features on one layer do not align perfectly with features on another.

The Challenge of Precision Drilling

The material's softness also complicates drilling, especially for vias that connect different layers.

The drill bit can push the pliable material aside rather than cutting it cleanly. This results in misalignment of drill holes and pads, compromising the integrity of the electrical connections.

Consequence for High-Frequency Performance

These seemingly minor manufacturing defects have significant consequences for circuits operating at very high frequencies, where physical precision is paramount.

Increased Return Loss

Misregistration and drilling misalignment create impedance discontinuities in the signal path.

These imperfections can cause signal reflections, leading to a measurable degradation known as return loss. For sensitive systems like advanced radar, this can compromise overall performance.

The Critical Role of Fabricator Expertise

It is crucial to understand that these disadvantages are not insurmountable.

An experienced fabricator with specific expertise in handling soft materials can implement specialized processes to mitigate these risks. However, this reliance on expert handling can increase costs and limit your choice of manufacturing partners.

Understanding the Trade-offs

Choosing unreinforced PTFE is a deliberate engineering decision that balances manufacturing challenges against electrical benefits.

The Disadvantage: Manufacturing Complexity

As outlined, the lack of rigidity introduces significant risk and requires specialized handling during lamination and drilling to achieve the required physical tolerances.

The Advantage: Eliminating Fiber Weave Effects

The primary reason to accept these challenges is to eliminate the glass fiber weave found in reinforced materials.

This weave can introduce inconsistencies in the dielectric constant and cause fiber weave skew, where signals traveling over different parts of the weave arrive at different times. Unreinforced PTFE provides a more uniform medium, which is critical for phase-sensitive applications.

Making the Right Choice for Your Application

Your decision should be based on a clear understanding of your project's primary goal.

- If your primary focus is manufacturability and cost control: A reinforced laminate is almost always a safer and more practical choice.

- If your primary focus is ultimate electrical performance at very high frequencies: Unreinforced PTFE is a superior option, provided you partner with a fabricator who has proven expertise with these materials.

Ultimately, the choice hinges on whether the pursuit of electrical purity justifies the inherent manufacturing risks.

Summary Table:

| Disadvantage | Impact on Manufacturing | Effect on Performance |

|---|---|---|

| Lack of Rigidity | Layer shifting, drilling misalignment | Increased return loss, signal degradation |

| Manufacturing Complexity | Requires specialized handling, expert fabrication | Higher costs, limited partner options |

| Trade-off with Electrical Benefits | Necessary for uniform dielectric properties | Eliminates fiber weave effects for high-frequency apps |

Need precision PTFE components for demanding applications?

At KINTEK, we specialize in manufacturing high-performance PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production and custom fabrication—from prototypes to high-volume orders—ensures your PTFE parts meet the strictest tolerances and performance requirements.

Let’s discuss your project: Contact us today to learn how we can help you overcome manufacturing challenges and achieve optimal results.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs