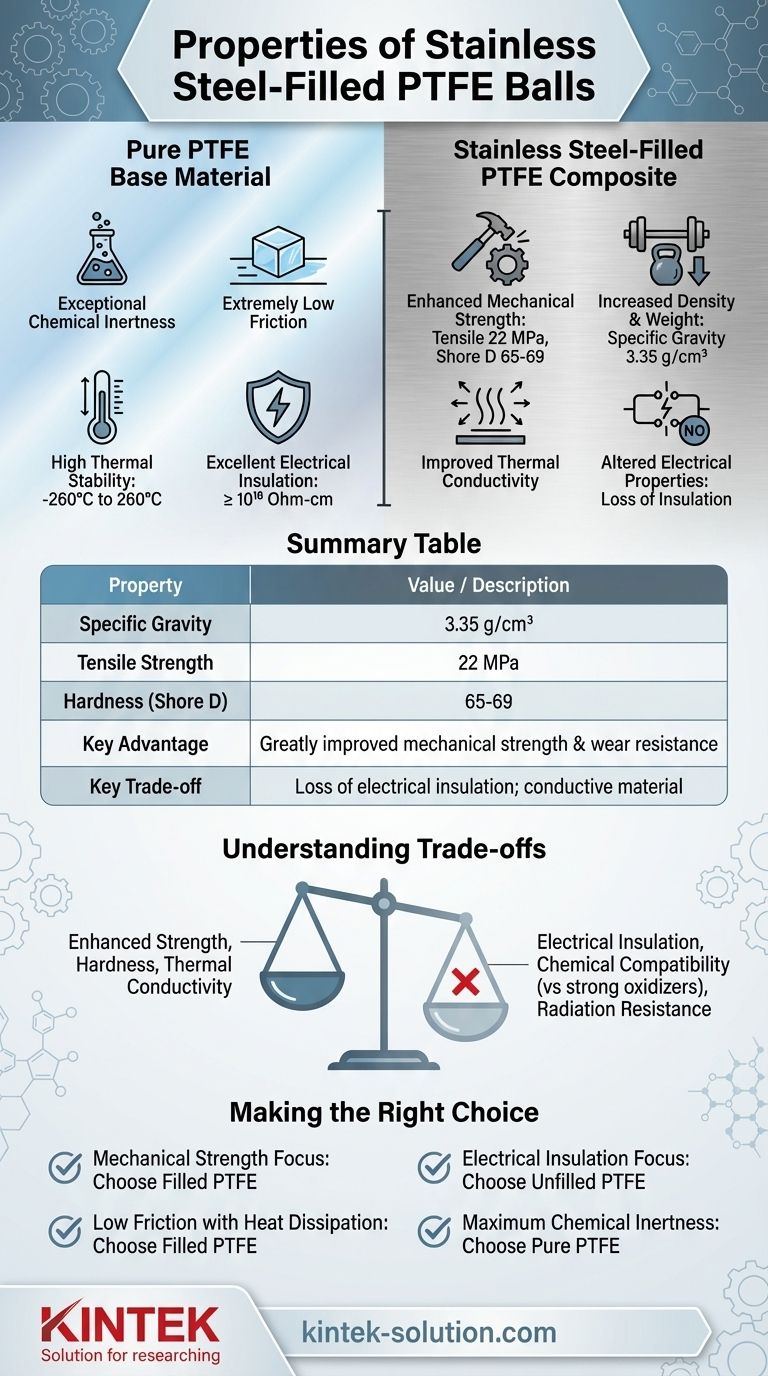

In short, stainless steel-filled PTFE balls are a composite material designed to enhance the mechanical properties of standard Polytetrafluoroethylene (PTFE). They possess a specific gravity of 3.35 g/cm³, a tensile strength of 22 MPa, and a Shore D hardness of 65-69. This filler significantly increases the material's strength, hardness, and density compared to pure PTFE.

By adding stainless steel particles to a PTFE base, you create a material that trades the exceptional electrical insulation of pure PTFE for vastly improved mechanical strength, wear resistance, and thermal conductivity.

Understanding the Base Material: Pure PTFE

To understand the composite, we must first appreciate the properties of its foundation. Pure PTFE is a remarkable polymer known for several key characteristics derived from its strong carbon-fluorine molecular bonds.

Exceptional Chemical Inertness

PTFE is resistant to nearly all chemicals and solvents. This makes it an ideal choice for components that will be exposed to corrosive environments.

Extremely Low Friction

Often known by the trade name Teflon, PTFE has one of the lowest coefficients of friction of any solid. This results in a non-stick, self-lubricating surface ideal for bearings and seals.

High Thermal Stability

Pure PTFE has a very wide operating temperature range, from as low as -260°C up to 260°C. However, it is a poor thermal conductor, meaning it does not dissipate heat well.

Excellent Electrical Insulation

With a volume resistivity of 10¹⁸ Ohm-cm or higher, PTFE is one of the best electrical insulators available.

The Impact of the Stainless Steel Filler

Introducing stainless steel particles into the PTFE matrix fundamentally changes the material's behavior, creating a composite with a new set of advantages and disadvantages.

Enhanced Mechanical Strength

This is the primary reason for the filler. The addition of steel dramatically increases tensile strength (22 MPa) and hardness (65-69 Shore D), making the material far more resistant to wear, deformation, and compression.

Increased Density and Weight

The specific gravity of the composite is 3.35 g/cm³, a significant increase from the 2.2 g/cm³ of pure PTFE. This added weight can be a critical design consideration.

Improved Thermal Conductivity

Metals are excellent thermal conductors. Adding steel particles allows the composite to dissipate heat far more effectively than pure PTFE, making it better for high-speed or high-load applications where friction generates heat.

Altered Electrical Properties

The most significant trade-off is the loss of electrical insulation. The presence of conductive metal particles throughout the material effectively negates PTFE's insulating properties.

Understanding the Trade-offs and Limitations

No material is perfect. Choosing stainless steel-filled PTFE requires acknowledging its specific compromises.

Compromised Electrical Insulation

This material is unsuitable for any application that requires electrical insulation. The steel filler creates a path for electrical current to flow.

Reduced Chemical Compatibility

While still highly resistant, the composite is vulnerable to strong oxidizing agents which can attack the stainless steel filler. Pure PTFE offers broader chemical resistance.

Poor Radiation Resistance

The PTFE base has poor resistance to high-energy radiation, and the steel filler does not mitigate this weakness.

Making the Right Choice for Your Application

Selecting the correct material depends entirely on your primary engineering goal.

- If your primary focus is mechanical strength and wear resistance: The hardness and tensile strength of stainless steel-filled PTFE make it an excellent choice over the unfilled version.

- If your primary focus is electrical insulation: You must use unfilled, virgin PTFE, as the stainless steel filler makes the composite conductive.

- If your primary focus is low friction with heat dissipation: The enhanced thermal conductivity of the steel-filled variant makes it superior for managing friction-generated heat in bearings or seals.

- If your primary focus is maximum chemical inertness: Pure PTFE is the safer choice, especially if the component will be exposed to strong oxidizing agents.

By understanding these distinct properties, you can confidently select the material that precisely matches your engineering requirements.

Summary Table:

| Property | Value / Description |

|---|---|

| Specific Gravity | 3.35 g/cm³ |

| Tensile Strength | 22 MPa |

| Hardness (Shore D) | 65-69 |

| Key Advantage | Greatly improved mechanical strength & wear resistance |

| Key Trade-off | Loss of electrical insulation; conductive material |

Need high-performance PTFE components tailored to your specific requirements?

At KINTEK, we specialize in the precision manufacturing of PTFE components, including advanced composites like stainless steel-filled PTFE. Whether you need the enhanced strength and thermal conductivity of filled PTFE or the supreme chemical resistance of pure PTFE, our expertise ensures your parts meet exact specifications.

We serve the semiconductor, medical, laboratory, and industrial sectors with custom fabrication from prototypes to high-volume orders.

Contact our experts today to discuss your project and discover how our tailored PTFE solutions can enhance your application's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions