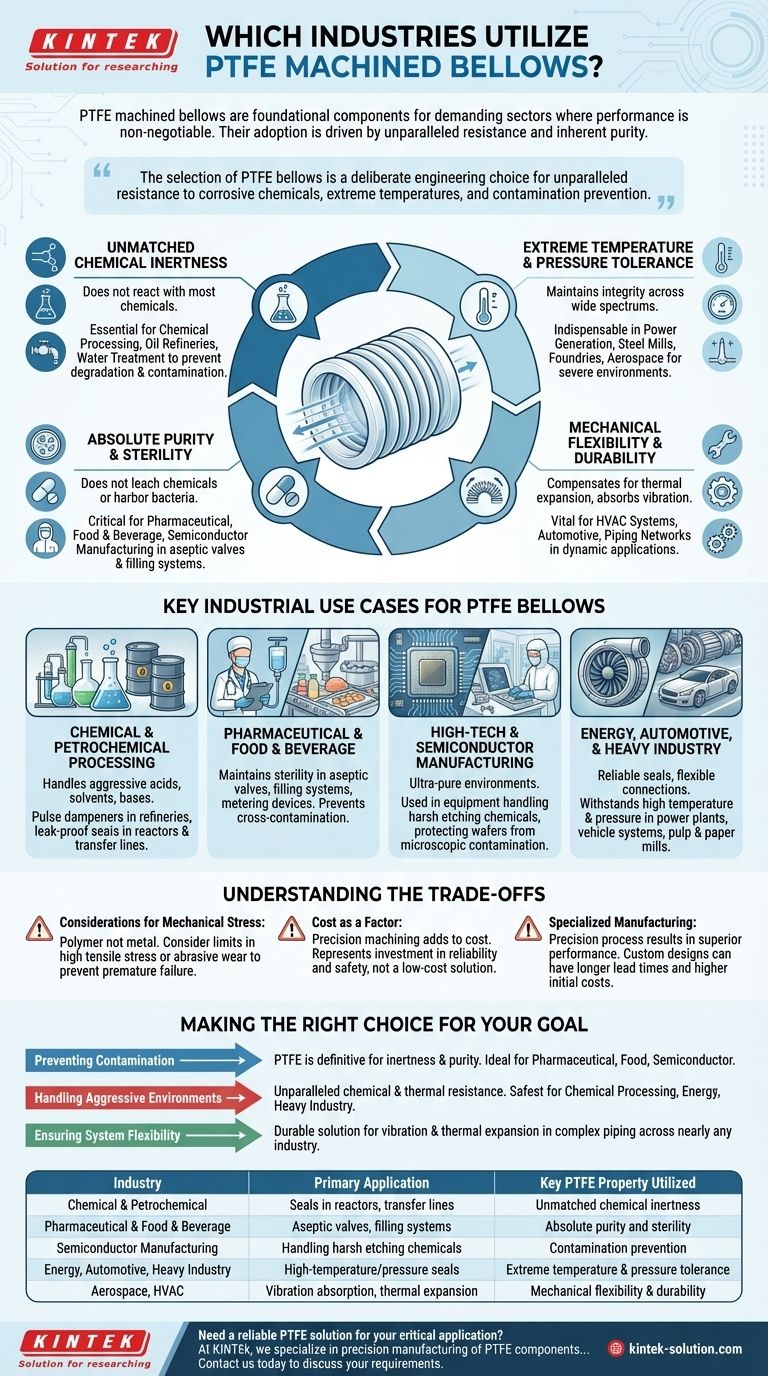

PTFE machined bellows are foundational components across a wide range of demanding industries. They are specified in sectors where performance is non-negotiable, including chemical processing, pharmaceuticals, food and beverage, automotive, semiconductor manufacturing, energy, and aerospace. Their adoption is driven by an ability to perform reliably under conditions that would cause most other materials to fail.

The selection of PTFE bellows is not arbitrary; it is a deliberate engineering choice driven by the material's unparalleled resistance to corrosive chemicals, extreme temperatures, and its inherent purity, which is critical for preventing contamination in sensitive processes.

Why PTFE is the Material of Choice for Critical Applications

The value of a PTFE bellow is not in the component itself, but in the problems it solves. Industries choose this material for a specific combination of properties that ensure operational safety, product purity, and system longevity.

Unmatched Chemical Inertness

Polytetrafluoroethylene (PTFE) is famously inert, meaning it does not react with most chemicals. This property is essential in industries like chemical processing, oil refineries, and water treatment, where bellows are constantly exposed to highly corrosive or aggressive media.

This resistance prevents both the degradation of the bellow and the contamination of the fluid it contains.

Extreme Temperature and Pressure Tolerance

PTFE maintains its integrity across a wide temperature spectrum and can be engineered to handle high-pressure applications.

This makes it indispensable in power generation, steel mills, foundries, and aerospace, where components must withstand severe operational environments without compromising performance.

Absolute Purity and Sterility

In the pharmaceutical, food and beverage, and semiconductor manufacturing industries, preventing contamination is the primary goal.

PTFE is an exceptionally pure material that does not leach chemicals or harbor bacteria. This makes it ideal for use in aseptic valves, filling systems, and any application where product purity is paramount.

Mechanical Flexibility and Durability

Despite its robustness, PTFE is highly flexible. Machined bellows are designed to compensate for thermal expansion, absorb vibration, and correct for misalignment in complex piping systems.

This durability in dynamic applications is vital across nearly all industries, from HVAC systems to intricate automotive and piping networks.

Key Industrial Use Cases for PTFE Bellows

Understanding the material properties helps explain where and why these components are deployed. The applications are a direct result of the material's strengths.

Chemical and Petrochemical Processing

In these environments, PTFE bellows are used to handle the most aggressive acids, solvents, and bases. They serve as pulse dampeners in refineries and provide flexible, leak-proof seals in chemical reactors and transfer lines.

Pharmaceutical and Food & Beverage

The core function here is maintaining sterility. PTFE bellows are integral to aseptic valves, filling systems, and metering devices, ensuring no cross-contamination between batches and protecting the final product.

High-Tech and Semiconductor Manufacturing

The manufacturing of microchips requires ultra-pure environments. PTFE bellows are used in equipment that handles harsh etching chemicals, where even microscopic contamination could ruin entire wafers of electronics.

Energy, Automotive, and Heavy Industry

From power plants to vehicle fluid systems, PTFE bellows provide reliable seals and flexible connections that can withstand high temperatures and pressures. Their use in pulp and paper mills and foundries demonstrates their resilience in harsh physical environments.

Understanding the Trade-offs

While highly capable, PTFE bellows are a specialized solution. Acknowledging their limitations is key to proper application.

Considerations for Mechanical Stress

Although durable, PTFE is a polymer, not a metal. In applications involving high tensile stress or abrasive wear, its mechanical limits must be carefully considered during the design phase to prevent premature failure.

Cost as a Factor

PTFE is a high-performance material, and the precision machining required for bellows adds to the cost. It is often more expensive than standard elastomers or metal alternatives, representing an investment in reliability and safety rather than a low-cost solution.

Specialized Manufacturing

The term "machined bellow" implies a precise manufacturing process. This results in superior performance but means that custom designs can have longer lead times and higher initial costs compared to molded or formed components.

Making the Right Choice for Your Goal

The decision to use a PTFE bellow should be based on the primary challenge you need to solve.

- If your primary focus is preventing contamination: PTFE is the definitive choice for its inertness and purity, making it ideal for pharmaceutical, food, and semiconductor applications.

- If your primary focus is handling aggressive environments: The unparalleled chemical and thermal resistance of PTFE makes it the safest and most reliable option for chemical processing, energy, and heavy industry.

- If your primary focus is ensuring system flexibility: PTFE bellows provide a durable solution for absorbing vibration and thermal expansion in complex piping systems across nearly any industry.

Understanding these core strengths allows you to specify PTFE bellows with confidence, knowing they are the correct technical solution for the most demanding applications.

Summary Table:

| Industry | Primary Application | Key PTFE Property Utilized |

|---|---|---|

| Chemical & Petrochemical | Seals in reactors, transfer lines | Unmatched chemical inertness |

| Pharmaceutical & Food & Beverage | Aseptic valves, filling systems | Absolute purity and sterility |

| Semiconductor Manufacturing | Handling harsh etching chemicals | Contamination prevention |

| Energy, Automotive, Heavy Industry | High-temperature/pressure seals | Extreme temperature & pressure tolerance |

| Aerospace, HVAC | Vibration absorption, thermal expansion | Mechanical flexibility & durability |

Need a reliable PTFE solution for your critical application?

At KINTEK, we specialize in precision manufacturing of PTFE components—including custom machined bellows—for semiconductor, medical, laboratory, industrial, and other specialized industries. Whether you require prototypes or high-volume orders, our expertise ensures your components meet the highest standards for chemical resistance, purity, and durability.

Contact us today to discuss your specific requirements and let our team deliver a solution that enhances your operational safety and product integrity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- How do lined valves compare to plastic pipes in terms of pressure and temperature resistance? Unlock Superior Performance

- What are the advantages of using PTFE guide strips in industrial applications? Enhance Equipment Life & Efficiency

- What medical benefits does PTFE's low friction and non-stick surface provide? Minimize Patient Trauma & Complications

- In which industries are PTFE bushes commonly used? A Guide to High-Performance Applications

- What are the key considerations when choosing an O-ring? A Guide to Reliable Sealing Performance

- What are the challenges of cleaning Teflon residue from a screw and barrel? A Guide to Safe, Effective Removal

- What are the key properties of PTFE valves? Ensure Purity, Safety, and Reliability in Demanding Processes

- How are Teflon sheets used in Direct-to-Garment (DTG) printing? Achieve a Professional, Durable Finish