In the medical field, PTFE's low friction and non-stick surface are crucial for minimizing patient trauma and reducing complications. These properties allow medical devices like catheters to glide smoothly through blood vessels and prevent wound dressings from sticking to healing tissue, which directly enhances patient safety and comfort during procedures and recovery.

The core challenge in medical device design is managing the interaction between a foreign material and sensitive biological tissue. PTFE's unique molecular structure solves this by creating an exceptionally smooth, non-reactive surface that reduces frictional damage and prevents biological adhesion, leading to safer procedures and better patient outcomes.

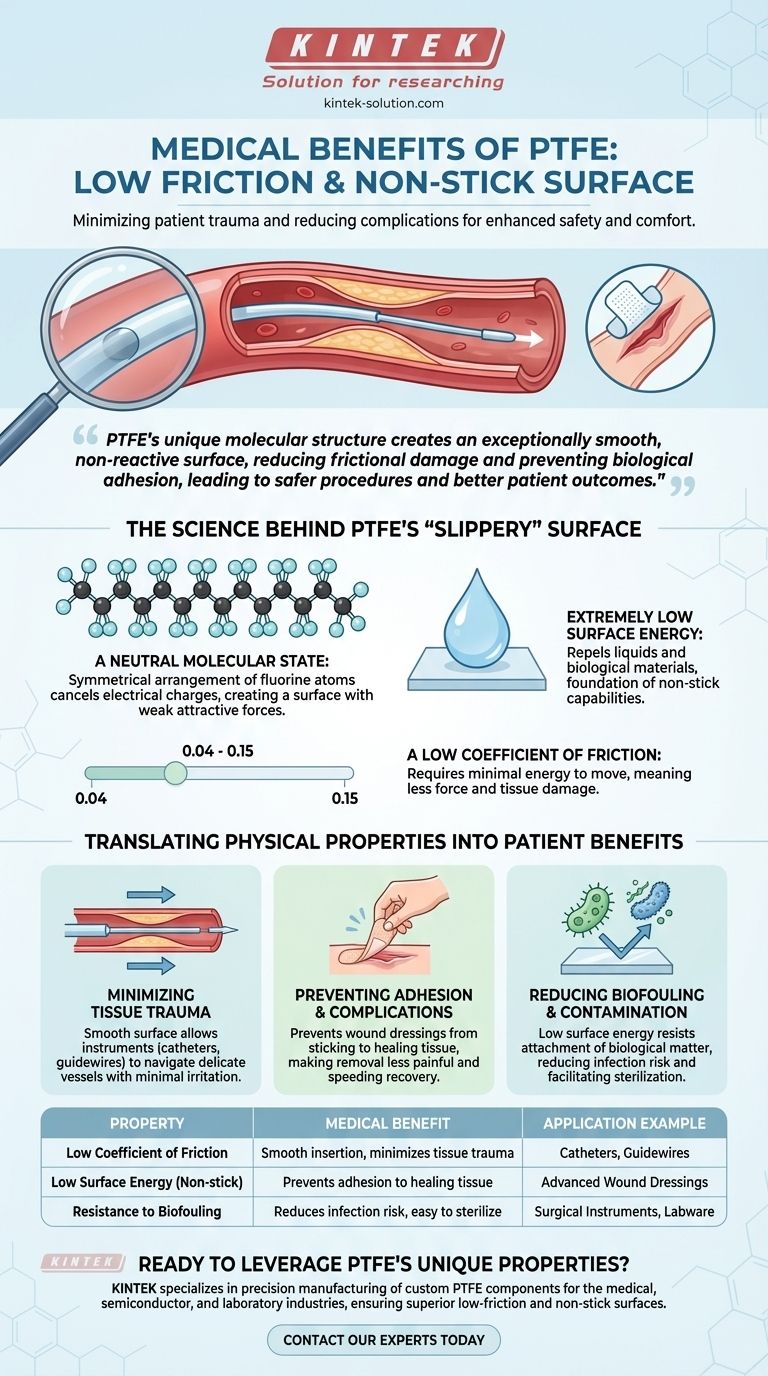

The Science Behind PTFE's "Slippery" Surface

To understand the medical benefits, we must first look at the fundamental properties of Polytetrafluoroethylene (PTFE). Its unique performance is not an accident but a direct result of its molecular architecture.

A Neutral Molecular State

PTFE is composed of long chains of carbon atoms completely surrounded by fluorine atoms. The symmetrical arrangement of these atoms causes their electrical charges to cancel each other out.

This creates a neutral electronic state, meaning the surface has very weak forces of attraction for other molecules.

Extremely Low Surface Energy

Because PTFE's surface is electronically neutral, liquids and biological materials are not attracted to it. This property is known as low surface energy.

Think of it like water beading up on a freshly waxed car. The surface actively repels substances, which is the foundation of its non-stick and anti-fouling capabilities.

A Low Coefficient of Friction

Quantitatively, PTFE has one of the lowest coefficients of friction of any solid, typically between 0.04 and 0.15.

This means it requires very little energy to move an object across its surface. In a medical context, this translates to less force and less potential for tissue damage.

Translating Physical Properties into Patient Benefits

These fundamental characteristics provide tangible advantages when PTFE is used in devices that come into contact with the human body.

Minimizing Tissue Trauma

For devices that must be navigated through the body, such as catheters or guidewires, low friction is paramount.

The smooth surface allows these instruments to be inserted and maneuvered through delicate blood vessels and other passages with minimal irritation or damage to the surrounding tissue.

Preventing Adhesion and Complications

PTFE's non-stick surface is critical for applications like advanced wound dressings.

It prevents the dressing from adhering to the sensitive, healing wound bed. This makes removal significantly less painful and avoids disrupting the new tissue, which speeds up recovery.

Reducing Biofouling and Contamination

The material's low surface energy makes it difficult for bacteria, proteins, and other biological matter to attach. This is known as resistance to biofouling.

This property helps reduce the risk of device-related infections and ensures instruments or containers made from PTFE are easy to clean and sterilize, promoting a hygienic environment.

Understanding the Trade-offs

While its properties are highly beneficial, PTFE is not the solution for every medical application. Its unique molecular structure also results in certain limitations.

Low Abrasion Resistance

The same weak intermolecular forces that make PTFE slippery also make it a relatively soft material.

It can be susceptible to scratching and mechanical wear in high-stress or long-term applications, which must be considered during the device design phase.

Difficulty in Bonding

Because nothing sticks to PTFE, it is also notoriously difficult to bond PTFE to other materials.

Engineers must use special surface treatments like chemical etching to create a bondable surface, which adds complexity and cost to the manufacturing process.

Applying This to Your Medical Application

The specific benefit you leverage depends entirely on the function of the medical device.

- If your primary focus is device navigation (catheters, endoscopes): The low coefficient of friction is the most critical property, as it ensures smooth, atraumatic insertion and movement.

- If your primary focus is wound care or implants: The low surface energy (non-stick) is key to preventing adhesion to tissue, reducing pain, and minimizing the risk of biofouling.

- If your primary focus is hygiene and sterility (labware, instruments): The easy-to-clean, non-stick surface is the main advantage for preventing cross-contamination and ensuring sterility.

Ultimately, PTFE's molecular inertness translates directly into creating safer, more effective, and less invasive medical technologies.

Summary Table:

| Property | Medical Benefit | Application Example |

|---|---|---|

| Low Coefficient of Friction | Smooth insertion, minimizes tissue trauma | Catheters, guidewires |

| Low Surface Energy (Non-stick) | Prevents adhesion to healing tissue | Advanced wound dressings |

| Resistance to Biofouling | Reduces infection risk, easy to sterilize | Surgical instruments, labware |

Ready to leverage PTFE's unique properties for your medical device?

KINTEK specializes in the precision manufacturing of custom PTFE components—from seals and liners to complex labware—for the medical, semiconductor, and laboratory industries. Our expertise ensures your devices benefit from superior low-friction and non-stick surfaces, enhancing patient safety and comfort.

Contact our experts today to discuss your project requirements, from prototypes to high-volume production.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs