To be direct, PTFE (Polytetrafluoroethylene) bushes are used across a vast spectrum of demanding industries. The most common include chemical processing, automotive, aerospace and defense, food and pharmaceutical manufacturing, and in precision equipment like textile or printing machinery.

The core reason for this widespread adoption is not a single feature, but a unique combination of properties. PTFE bushes are a go-to solution in environments where low friction, extreme chemical resistance, and high-temperature stability are non-negotiable.

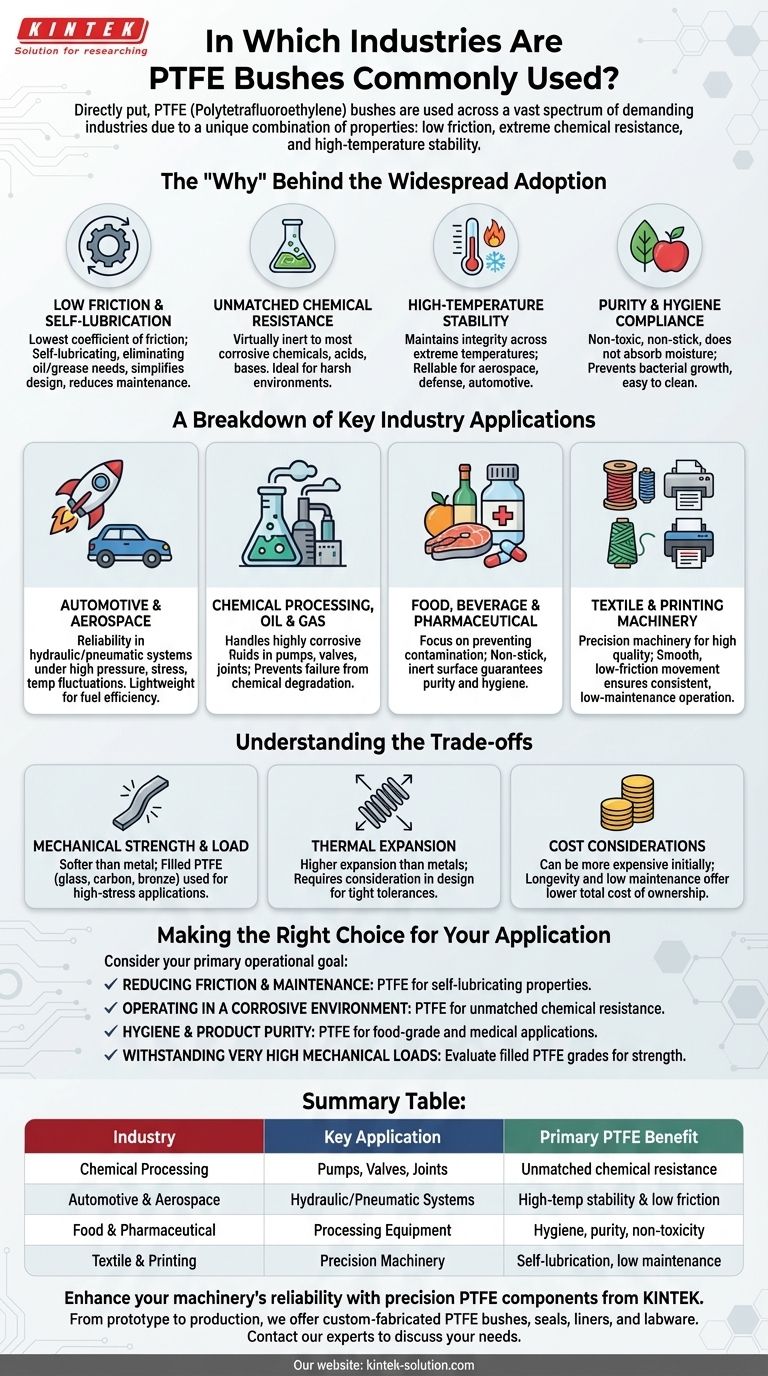

The "Why" Behind the Widespread Adoption

The versatility of PTFE stems from its fundamental material characteristics. Each property solves a critical engineering challenge faced by different industries, making it an invaluable component in modern machinery.

Exceptionally Low Friction and Self-Lubrication

PTFE possesses one of the lowest coefficients of friction of any solid material. This means components can move against each other with minimal resistance and wear.

Because they are self-lubricating, PTFE bushes eliminate the need for external oils or greases, which simplifies design, reduces maintenance, and prevents contamination.

Unmatched Chemical Resistance

PTFE is virtually inert and does not react with most corrosive chemicals, acids, or bases.

This property is critical in industries like chemical processing, oil and gas, and pharmaceuticals, where bushes are constantly exposed to harsh substances that would rapidly degrade traditional metal bearings.

High-Temperature Stability

These components maintain their structural integrity and performance across a wide range of temperatures.

This makes them essential for aerospace, defense, and high-performance automotive applications where components must function reliably under extreme heat or cold.

Purity and Hygiene Compliance

The material is non-toxic, non-stick, and does not absorb moisture, preventing bacterial growth.

This makes it an ideal choice for the food, beverage, and pharmaceutical industries, where hygiene standards are strict and equipment must be easily cleaned.

A Breakdown of Key Industry Applications

Seeing how PTFE bushes are applied in specific contexts reveals why they are often the superior choice over conventional materials.

Automotive and Aerospace

In these sectors, reliability is paramount. PTFE bushes and seals are used in hydraulic and pneumatic systems where high pressure, mechanical stress, and temperature fluctuations are common. Their light weight also contributes to fuel efficiency.

Chemical Processing, Oil & Gas

Equipment in this field often handles highly corrosive fluids. PTFE bushes are used in pumps, valves, and joints to ensure long service life and prevent catastrophic failures caused by chemical degradation.

Food, Beverage, and Pharmaceutical

Here, the focus is on preventing contamination. PTFE's non-stick surface and chemical inertness ensure that it does not react with products or cleaning agents, guaranteeing the purity of the final product.

Textile and Printing Machinery

These industries rely on precision machinery for high-quality output. The smooth, low-friction movement provided by PTFE bushes ensures consistent and reliable operation with minimal maintenance downtime.

Understanding the Trade-offs

While extremely capable, PTFE is not a universal solution. Understanding its limitations is key to successful implementation.

Mechanical Strength and Load

Standard PTFE is softer than metal and may deform under very high mechanical loads. For high-stress applications, filled PTFE—which includes additives like glass, carbon, or bronze—is used to significantly improve strength and wear resistance.

Thermal Expansion

PTFE has a higher coefficient of thermal expansion than most metals. This means it expands and contracts more with temperature changes, a factor that engineers must account for when designing parts with tight tolerances.

Cost Considerations

While offering immense value, high-performance PTFE can be more expensive than some traditional bearing materials. However, its longevity and low-maintenance nature often result in a lower total cost of ownership.

Making the Right Choice for Your Application

To determine if PTFE bushes are the correct component for your project, consider your primary operational goal.

- If your primary focus is reducing friction and maintenance: PTFE is an excellent choice due to its self-lubricating properties.

- If your primary focus is operating in a corrosive environment: Its unmatched chemical resistance makes it a leading candidate.

- If your primary focus is hygiene and product purity: PTFE is a standard and trusted material in food-grade and medical applications.

- If your primary focus is withstanding very high mechanical loads: You should evaluate filled PTFE grades to ensure the necessary strength and durability.

Ultimately, selecting PTFE bushes is a strategic decision to enhance reliability and performance in environments where other materials would fail.

Summary Table:

| Industry | Key Application | Primary PTFE Benefit |

|---|---|---|

| Chemical Processing | Pumps, Valves, Joints | Unmatched chemical resistance |

| Automotive & Aerospace | Hydraulic/Pneumatic Systems | High-temperature stability & low friction |

| Food & Pharmaceutical | Processing Equipment | Hygiene, purity, non-toxicity |

| Textile & Printing | Precision Machinery | Self-lubrication, low maintenance |

Enhance your machinery's reliability with precision PTFE components from KINTEK.

Whether you're in the semiconductor, medical, laboratory, or industrial sector, our custom-fabricated PTFE bushes, seals, liners, and labware are engineered to excel in demanding environments. We specialize in creating solutions that offer low friction, extreme chemical resistance, and high-temperature stability, from initial prototypes to high-volume production runs.

Ready to solve your toughest engineering challenges? Contact our experts today to discuss your specific application needs and receive a custom quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability