In industrial applications, PTFE guide strips provide a powerful combination of extremely low friction, exceptional chemical resistance, and high-temperature tolerance. These properties work together to protect equipment from wear, reduce maintenance requirements, and improve the overall efficiency and reliability of dynamic systems like hydraulic and pneumatic cylinders.

The core value of PTFE guide strips is not just in their material properties, but in their ability to solve the fundamental engineering problems of friction and wear. By creating a self-lubricating, wear-resistant barrier, they extend the life of expensive equipment and dramatically lower long-term operational costs.

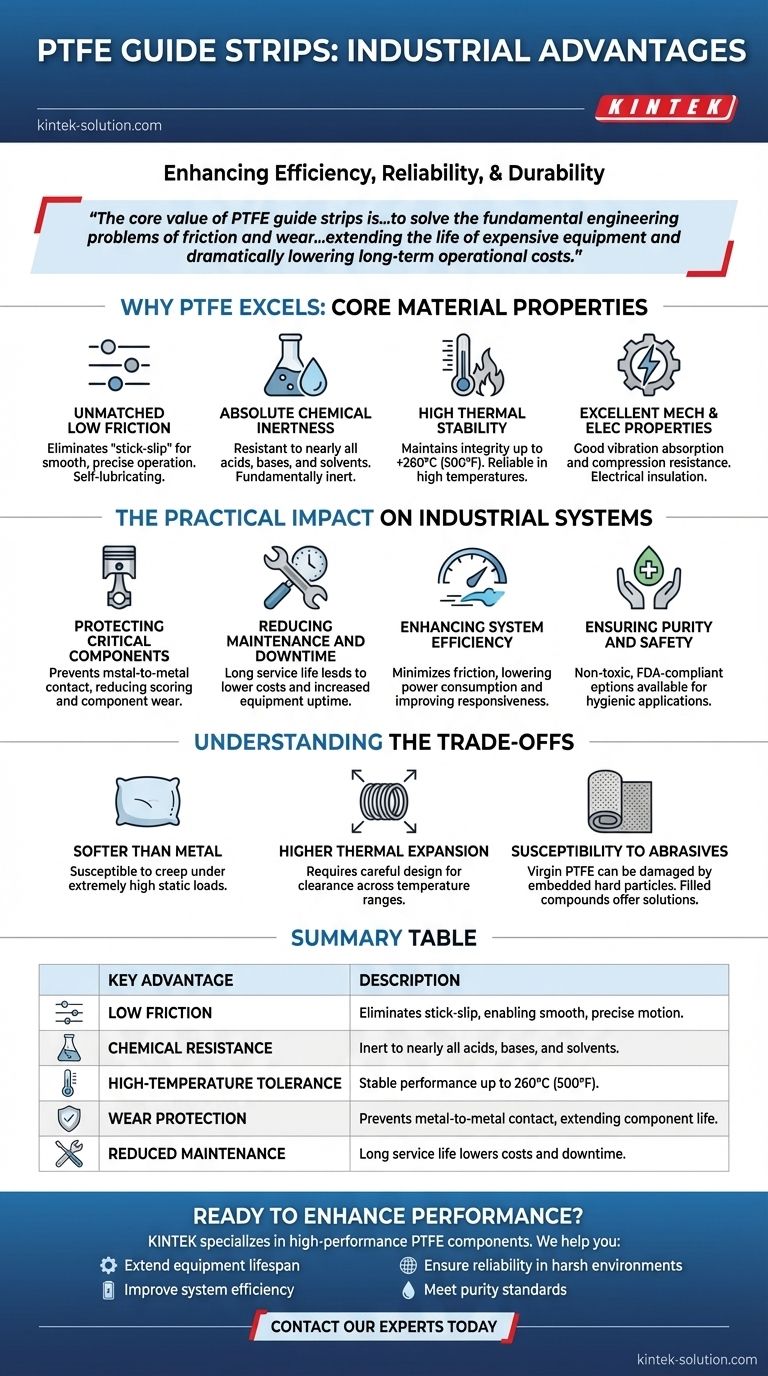

Why PTFE Excels: The Core Material Properties

To understand the benefits of PTFE guide strips, you must first understand the unique characteristics of Polytetrafluoroethylene (PTFE) itself. These intrinsic properties are what make it an ideal choice for demanding bearing and guide applications.

Unmatched Low Friction

PTFE possesses one of the lowest coefficients of friction of any solid material. This self-lubricating nature is critical for dynamic applications.

It effectively eliminates the "stick-slip" effect, where components jerk at the start of motion. This results in smoother, more precise, and more predictable equipment operation.

Absolute Chemical Inertness

PTFE is resistant to nearly all industrial chemicals, including aggressive acids, bases, and solvents. It is fundamentally inert.

This makes it the default choice for systems handling corrosive substances, from chemical processing plants to pharmaceutical manufacturing, where material degradation is not an option.

High Thermal Stability

PTFE guide strips maintain their integrity and performance across a wide temperature range, with a continuous working temperature of up to +260°C (500°F).

This thermal resilience ensures reliable performance in high-temperature hydraulic systems, engines, and other environments where lesser polymers would fail.

Excellent Mechanical & Electrical Properties

Beyond its primary benefits, PTFE offers good vibration absorption and high compression resistance for a polymer, allowing it to handle significant radial loads without fracturing.

Furthermore, its excellent electrical insulation properties make it valuable for applications where preventing electrical conductivity is a design requirement.

The Practical Impact on Industrial Systems

The material properties of PTFE translate directly into tangible operational advantages, solving common challenges in hydraulics, pneumatics, and mechanical assemblies.

Protecting Critical Components

The primary function of a guide strip is to prevent metal-to-metal contact between moving parts, such as a piston and a cylinder bore.

By absorbing transverse (radial) loads, PTFE guide strips prevent scoring and damage to critical surfaces, which is the leading cause of premature seal failure and component wear.

Reducing Maintenance and Downtime

The combination of high wear resistance and chemical durability means PTFE guide strips have a very long service life.

This directly translates to lower maintenance costs and, more importantly, reduced equipment downtime. The reliability of these simple components protects the uptime of the entire system.

Enhancing System Efficiency

By minimizing friction, PTFE guide strips allow systems to operate more efficiently. Less energy is wasted overcoming resistance, which can lead to lower power consumption.

The smooth, responsive motion they enable also improves the precision and overall performance of dynamic sealing systems.

Ensuring Purity and Safety

PTFE is inherently non-toxic and can be manufactured to be food-grade and FDA-compliant.

This makes it essential for hygienic applications in the food and beverage, pharmaceutical, and medical industries, where preventing product contamination is paramount.

Understanding the Trade-offs

While highly effective, PTFE is not a universal solution. An objective assessment requires understanding its limitations to ensure proper design and application.

Softer than Metal

PTFE is a polymer, not a metal. While it has good compression resistance, it is much softer than steel or bronze. In applications with extremely high, static radial loads, it may be susceptible to creep (slow deformation over time).

Higher Thermal Expansion

Like most polymers, PTFE has a higher coefficient of thermal expansion than metals. This must be accounted for during design, particularly with wide operating temperature ranges, to ensure proper clearances are maintained.

Susceptibility to Abrasives

While virgin PTFE has excellent wear resistance due to its low friction, it can be susceptible to damage from hard abrasive particles embedded in a system. For such environments, filled PTFE compounds (e.g., bronze-filled or carbon-filled) are often used to increase hardness and abrasion resistance.

Making the Right Choice for Your Application

Selecting the right material is about matching its properties to your primary engineering goal. PTFE guide strips offer a versatile solution for improving long-term reliability.

- If your primary focus is extending equipment life: PTFE is an ideal choice for preventing metal-to-metal contact and absorbing vibrations that cause wear.

- If your primary focus is operational efficiency: The ultra-low friction of PTFE reduces energy loss and eliminates stick-slip for smoother, more precise motion.

- If your primary focus is operating in harsh environments: PTFE’s unmatched chemical and thermal resistance ensures survival where other materials would quickly degrade.

- If your primary focus is hygiene and product purity: Its inert, non-toxic, and FDA-compliant nature makes PTFE the safe and reliable option for sensitive applications.

Ultimately, integrating PTFE guide strips is a strategic decision to enhance the durability and performance of your mechanical systems.

Summary Table:

| Key Advantage | Description |

|---|---|

| Low Friction | Eliminates stick-slip, enabling smooth, precise motion. |

| Chemical Resistance | Inert to nearly all acids, bases, and solvents. |

| High-Temperature Tolerance | Stable performance up to 260°C (500°F). |

| Wear Protection | Prevents metal-to-metal contact, extending component life. |

| Reduced Maintenance | Long service life lowers costs and downtime. |

Ready to solve friction, wear, and chemical resistance challenges in your equipment?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom guide strips. We serve the semiconductor, medical, laboratory, and industrial sectors, delivering solutions from prototypes to high-volume orders.

We can help you:

- Extend equipment lifespan and reduce maintenance costs.

- Improve system efficiency with ultra-low friction components.

- Ensure reliability in harsh chemical or high-temperature environments.

- Meet purity standards for sensitive applications.

Contact our experts today to discuss your specific requirements and discover how our PTFE solutions can enhance your project's performance and durability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Can expanded PTFE gaskets handle high temperatures? Ensure Reliable Sealing Up to 500°F

- What are the key characteristics of PTFE coated fasteners? Enhance Durability in Harsh Environments

- What are the benefits of Teflon bellow mechanical seals for manufacturers and suppliers? Unlock New Market Opportunities

- What media restrictions apply to PTFE lined butterfly valves? Ensure Long-Term Reliability for Corrosive Fluids

- What types of media are suitable for PTFE Bellow Mechanical Seals? Sealing the Most Aggressive Chemicals

- What are the challenges of cleaning Teflon residue from a screw and barrel? A Guide to Safe, Effective Removal

- What are the typical friction coefficient values for PTFE? A Guide to Low-Friction Performance

- How do FEP and PTFE encapsulated O-rings compare to traditional O-rings? A Hybrid Solution for Harsh Environments