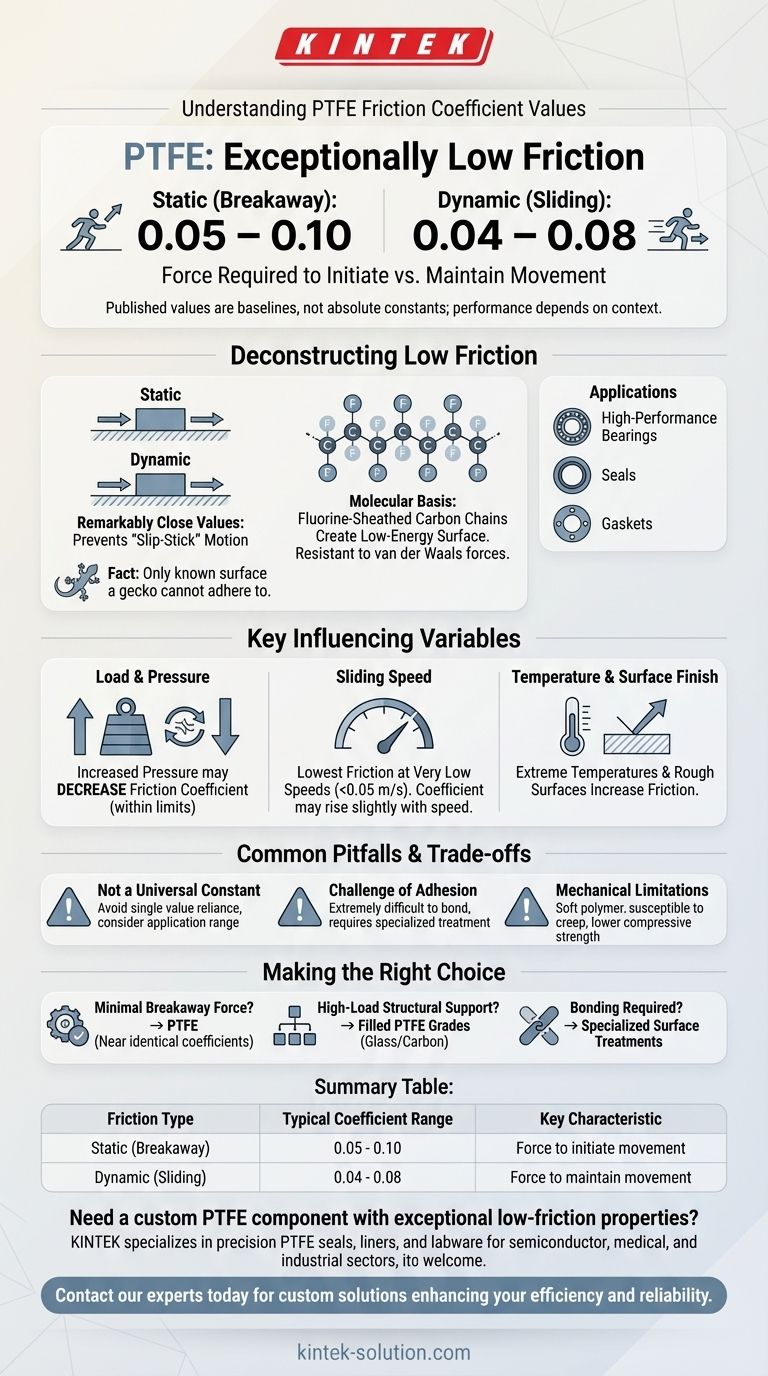

For practical engineering purposes, the coefficient of friction for PTFE (Polytetrafluoroethylene) is exceptionally low. Its static coefficient of friction, the force required to initiate movement, typically ranges from 0.05 to 0.10. The dynamic coefficient of friction, the force needed to maintain movement, is even lower, generally falling between 0.04 and 0.08.

While PTFE's published friction values are among the lowest for any solid material, they are not absolute constants. True performance in any application is influenced by external factors such as load, speed, and temperature, making it critical to understand the context behind the numbers.

Deconstructing PTFE's Uniquely Low Friction

To properly leverage PTFE, we must look beyond the numbers and understand the molecular basis for its performance. This characteristic dictates its ideal applications and its limitations.

Static vs. Dynamic Friction

The static coefficient represents the initial "stiction" or breakaway force. The dynamic (or kinetic) coefficient represents the resistance during sliding motion.

For PTFE, these two values are remarkably close. This proximity is highly desirable in mechanical systems, as it prevents the jerky "slip-stick" motion common in materials where static friction is significantly higher than dynamic friction.

The Molecular Basis for a "Slippery" Surface

PTFE's low friction is not a surface treatment; it is an inherent property of its molecular structure. The long carbon chains of the polymer are completely sheathed by fluorine atoms.

These fluorine atoms are tightly bonded and create a uniform, low-energy surface. This structure is highly resistant to the weak intermolecular attractions known as van der Waals forces, which are a primary component of friction in most other materials.

Practical Implications and Applications

This non-stick, low-friction nature makes PTFE an ideal material for specific, demanding roles.

It is frequently used for high-performance bearings, seals, and gaskets, where reducing energy loss and preventing wear are paramount. Its properties are so effective that it is the only known surface to which a gecko cannot adhere.

Understanding the Key Variables

The textbook values for PTFE's friction coefficient are a baseline. In any real-world scenario, you must account for the operating conditions, which can modify the effective friction.

The Effect of Load and Pressure

The load applied to the PTFE surface plays a significant role. Generally, for PTFE, an increase in pressure can lead to a decrease in the friction coefficient within its operational limits.

The Role of Sliding Speed

Sliding velocity also alters performance. The lowest friction values for PTFE are typically observed at very low speeds, such as under 10 ft/min (0.05 m/s). As speed increases, the coefficient can rise slightly.

Temperature and Surface Finish

Both ambient temperature and the finish of the mating surface are important factors. Extreme temperatures can alter the mechanical properties of PTFE, and a rougher mating surface will naturally lead to higher friction and wear than a polished one.

Common Pitfalls and Trade-offs

The extreme properties that make PTFE so useful also introduce critical design trade-offs that are often overlooked.

It Is Not a Universal Constant

Relying on a single published value for the coefficient of friction in a critical design is a common mistake. Always consider the full range of potential values based on your specific application's load, speed, and environmental conditions.

The Challenge of Adhesion

The same molecular property that repels other materials and creates low friction also makes PTFE extremely difficult to bond. Standard adhesives will not work, and joining it to other substrates requires specialized and costly surface preparation techniques like chemical etching.

Mechanical Limitations

While its friction properties are exceptional, PTFE is a relatively soft polymer. It is susceptible to creep (deformation under sustained load) and has lower compressive strength and wear resistance compared to harder bearing materials like metals or filled polymers.

Making the Right Choice for Your Application

Selecting or specifying PTFE requires aligning its unique characteristics with your primary engineering goal.

- If your primary focus is minimal breakaway force: PTFE is an exceptional choice because its static and dynamic friction coefficients are nearly identical, ensuring smooth motion initiation.

- If your primary focus is high-load structural support: You must consider using filled grades of PTFE (e.g., glass- or carbon-filled) to improve creep resistance and compressive strength.

- If your application requires bonding to other materials: Plan for specialized surface treatments from the outset, as standard adhesion is practically impossible.

By understanding these factors, you can effectively leverage PTFE's remarkable properties to design highly efficient and reliable mechanical systems.

Summary Table:

| Friction Type | Typical Coefficient Range | Key Characteristic |

|---|---|---|

| Static (Breakaway) | 0.05 - 0.10 | Force to initiate movement |

| Dynamic (Sliding) | 0.04 - 0.08 | Force to maintain movement |

Need a custom PTFE component with exceptional low-friction properties?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, and labware for the semiconductor, medical, and industrial sectors. Our expertise ensures your components are designed to deliver optimal performance, accounting for critical factors like load, speed, and temperature. We offer custom fabrication from prototypes to high-volume orders.

Contact our experts today to discuss how our PTFE solutions can enhance your application's efficiency and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments