For manufacturers and suppliers, the primary benefits of Teflon (PTFE) bellow mechanical seals are their material versatility and robust performance, which unlocks access to a wide range of demanding industries. This allows them to move beyond being simple parts providers and become suppliers of custom-engineered, high-value solutions, often supplemented by profitable long-term support and maintenance services.

The core business advantage lies in providing a single sealing technology that solves the most difficult challenges—corrosive chemicals, high temperatures, and mechanical misalignment—making it an indispensable component for industries where failure is not an option.

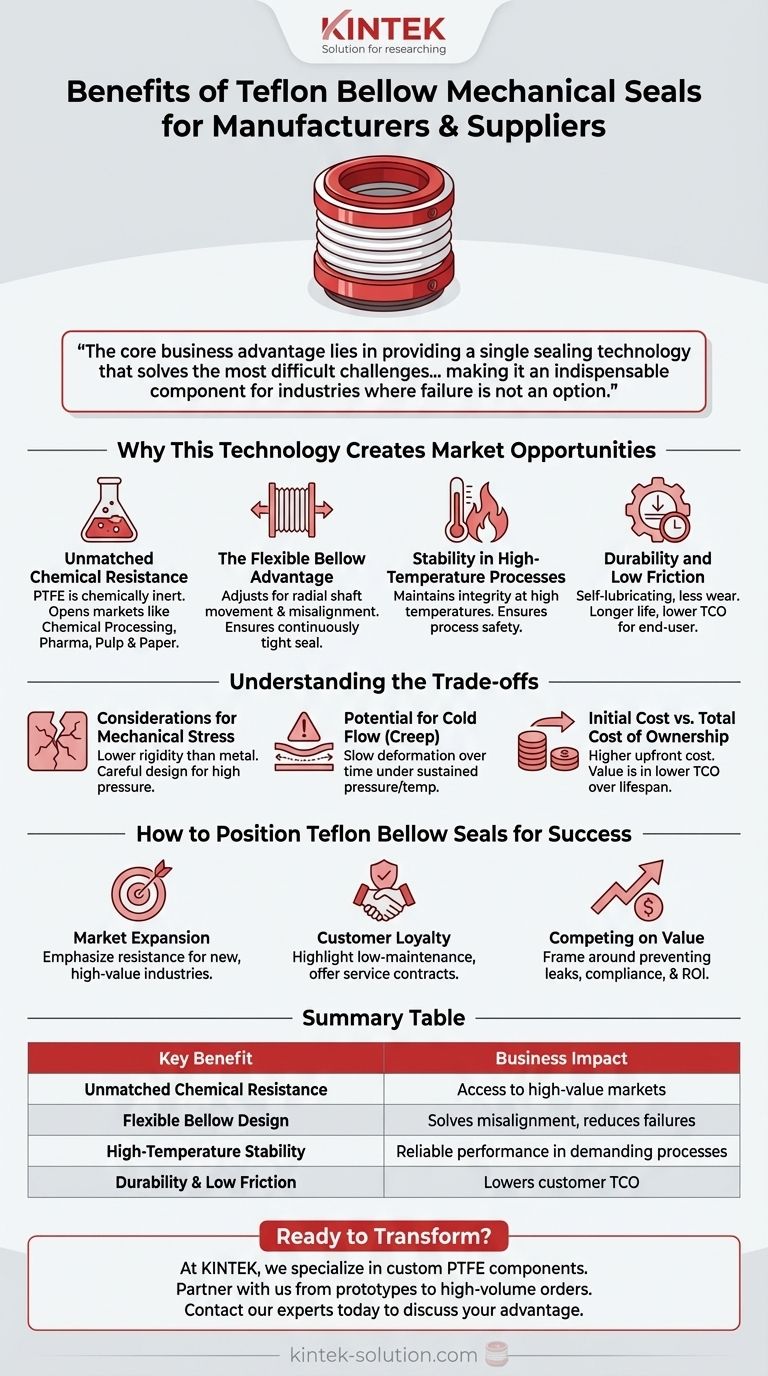

Why This Technology Creates Market Opportunities

The value proposition for a manufacturer or supplier is directly tied to the technical superiority of the product. Teflon bellow seals excel in environments where lesser materials would quickly fail, creating a durable market demand.

Unmatched Chemical Resistance

PTFE is one of the most chemically inert materials used in industry. This property makes these seals the default choice for applications involving aggressive acids, bases, and solvents.

This opens up critical markets such as chemical processing, pharmaceuticals, and pulp and paper manufacturing, where equipment integrity is paramount.

The Flexible Bellow Advantage

The signature "bellow" design is not just for show; it's a key mechanical feature. It allows the seal to flex, expand, and contract.

This flexibility means the seal can automatically adjust for radial shaft movement and minor misalignment, common issues in large rotating machinery like pumps and mixers. This ensures a continuously tight seal where a rigid seal might fail.

Stability in High-Temperature Processes

In processes like pulp digestion, extreme heat can compromise sealing performance. Teflon bellow seals maintain their integrity and sealing force at high temperatures.

This reliability prevents the escape of hazardous substances, ensuring process safety and equipment protection for the end-user, which is a powerful selling point.

Durability and Low Friction

PTFE is a self-lubricating material with a very low coefficient of friction. This translates directly to less wear and tear on both the seal and the equipment shaft.

For the end customer, this means longer operational life, reduced equipment downtime, and minimal maintenance costs—a compelling argument for a supplier to make.

Understanding the Trade-offs

To provide a complete picture, it's essential to understand the material's limitations. While PTFE is a superior material for many applications, it is not a universal solution.

Considerations for Mechanical Stress

PTFE is a polymer, not a metal. While durable, it has lower compressive strength and rigidity than materials like stainless steel or ceramics. In extremely high-pressure applications, the seal design must be engineered carefully to prevent deformation.

Potential for Cold Flow (Creep)

Under sustained pressure and temperature, PTFE can be subject to "creep," or cold flow, where the material slowly deforms over time. This is a known engineering characteristic that must be accounted for in the design of long-life, critical seals.

Initial Cost vs. Total Cost of Ownership

High-performance PTFE seals often have a higher initial purchase price than standard elastomeric or metal seals.

Therefore, the value conversation must shift from upfront cost to Total Cost of Ownership (TCO). The supplier's role is to demonstrate how the seal's reliability, longevity, and low maintenance requirements deliver a far lower TCO over the equipment's lifespan.

How to Position Teflon Bellow Seals for Success

As a manufacturer or supplier, your strategy should focus on leveraging the seal's strengths to solve specific customer problems.

- If your primary focus is market expansion: Emphasize the seal's unmatched chemical and temperature resistance to enter new, high-value industries like wastewater treatment and chemical manufacturing.

- If your primary focus is building customer loyalty: Highlight the low-maintenance, "set-it-and-forget-it" nature of the seals and offer value-added maintenance contracts to become a long-term partner.

- If your primary focus is competing on value: Frame the discussion around preventing costly leaks, ensuring regulatory compliance, and reducing equipment downtime, proving a higher return on investment.

Ultimately, offering Teflon bellow seals transforms a supplier from a parts provider into a critical problem-solver for the most demanding industrial applications.

Summary Table:

| Key Benefit | Business Impact for Manufacturers/Suppliers |

|---|---|

| Unmatched Chemical Resistance | Access to high-value markets like chemical processing and pharmaceuticals. |

| Flexible Bellow Design | Solves customer misalignment issues, reducing failure rates and support calls. |

| High-Temperature Stability | Enables reliable performance in demanding processes like pulp digestion. |

| Durability & Low Friction | Lowers customer TCO with longer seal life and reduced maintenance needs. |

Ready to transform your product line with high-performance PTFE seals?

At KINTEK, we specialize in the precision manufacturing of custom PTFE components, including bellow seals, for the semiconductor, medical, laboratory, and industrial sectors. We help manufacturers and suppliers like you deliver the reliability and chemical resistance your most demanding customers require.

Partner with us for custom fabrication from prototypes to high-volume orders. Contact our experts today to discuss how our PTFE solutions can become your competitive advantage.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components