In short, encapsulated O-rings are a hybrid solution. They merge the superior chemical and temperature resistance of a fluoropolymer jacket (like FEP or PTFE) with the flexibility and compression of a traditional elastomeric rubber core. This dual-material design allows them to vastly outperform standard O-rings in aggressive environments where a conventional seal would rapidly degrade and fail.

The core decision is not about which O-ring is "better," but which is appropriate for the environment. Encapsulated O-rings solve the chemical and thermal weaknesses of traditional rubber seals but introduce trade-offs in flexibility, installation sensitivity, and cost.

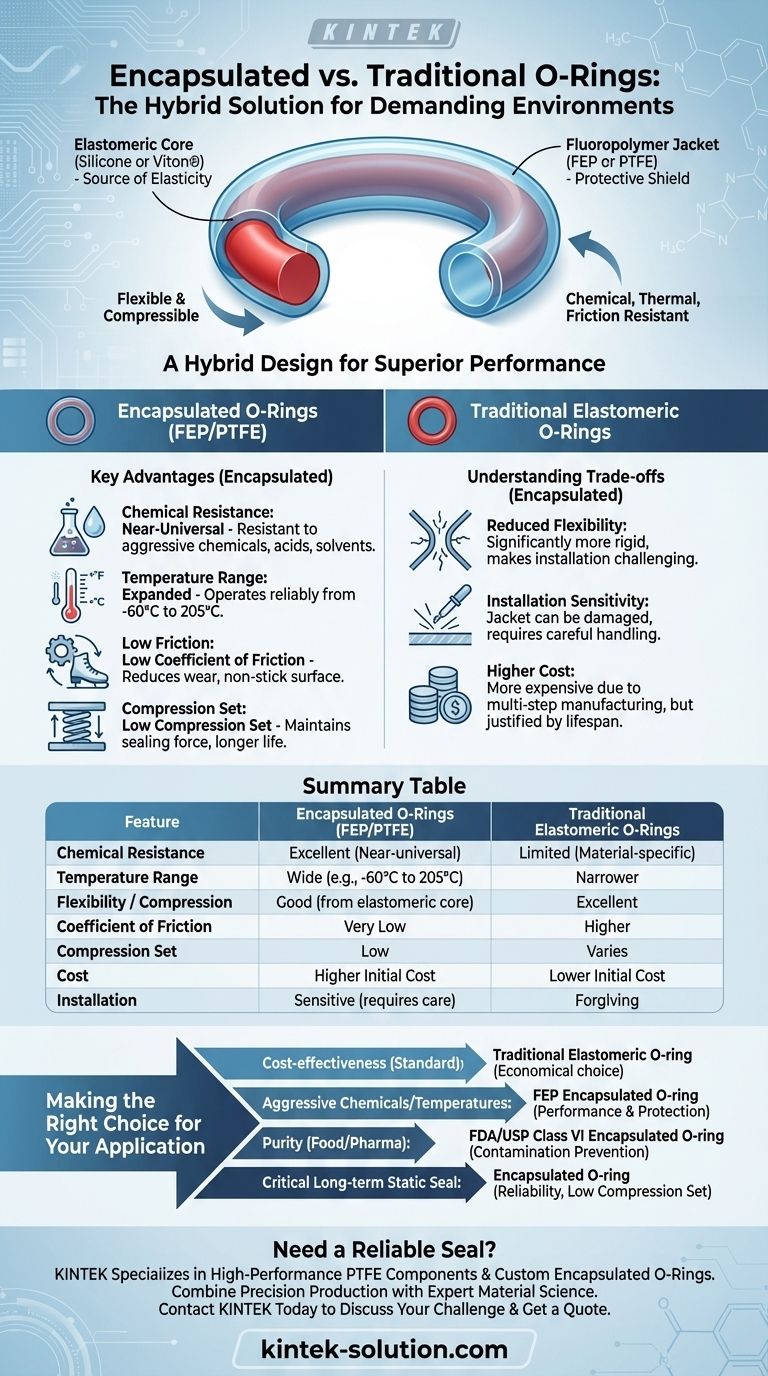

The Fundamental Design: A Best-of-Both-Worlds Approach

To understand the performance difference, you must first understand the construction. An encapsulated O-ring is not a single material but a composite of two distinct components.

The Elastomeric Core: The Source of Elasticity

The inner core is made from a conventional elastomer, typically Silicone or Viton® (FKM).

This core provides the O-ring's essential "springiness" and memory. It's responsible for generating the compressive force that creates a positive seal.

The Fluoropolymer Jacket: The Protective Shield

A thin, seamless jacket of FEP (Fluorinated Ethylene Propylene) or PTFE (Polytetrafluoroethylene) is extruded over the core.

This outer layer acts as a barrier, isolating the vulnerable rubber core from the surrounding environment. It provides virtually all of the chemical, thermal, and friction-resistance properties.

Key Advantages Over Traditional O-Rings

The hybrid design directly translates into measurable performance benefits in demanding applications, moving far beyond the capabilities of a standard nitrile or Viton seal.

Near-Universal Chemical Resistance

The FEP or PTFE jacket is chemically inert, making the O-ring resistant to a vast range of aggressive chemicals, including acids, bases, and solvents that would destroy a standard rubber seal.

This makes them ideal for chemical processing, pharmaceuticals, and other industries where media compatibility is critical.

Expanded Temperature Range

While the exact range depends on the core and jacket materials, FEP encapsulated O-rings can typically operate reliably from -60°C to 205°C (-75°F to 400°F).

This is a significantly wider operating window than many standard elastomers can tolerate without becoming brittle or degrading.

Low Coefficient of Friction

The fluoropolymer jacket has a very low-friction, non-stick surface. This reduces the force required to actuate parts, minimizes wear in dynamic sealing applications, and prevents sticking during assembly or maintenance.

Low Compression Set

Encapsulated O-rings resist taking a permanent "set" after being compressed for long periods. This ensures they maintain their sealing force over a much longer service life, reducing leaks and maintenance needs in critical static seals.

Understanding the Trade-offs and Limitations

While powerful, encapsulated O-rings are not a universal replacement for all other seals. Their specialized design comes with important considerations.

Reduced Flexibility

The fluoropolymer jacket is significantly more rigid than a pure elastomer. This makes the O-ring less flexible and gives it a "harder" feel, which can make installation more challenging.

Installation Sensitivity

The outer jacket, while durable, can be scratched or damaged by sharp edges or improper installation techniques. Any breach in the jacket exposes the inner core, completely negating the O-ring's chemical resistance benefits.

Higher Initial Cost

The multi-step manufacturing process for encapsulating the core makes these O-rings more expensive than standard, single-material seals. However, this cost is often justified by extended equipment lifespan and reduced downtime.

Sealing on Rough Surfaces

Because the outer jacket is less pliable than rubber, it may not conform as well to minor imperfections, scratches, or roughness on a sealing surface. A smooth, well-finished gland is more critical for optimal performance.

Making the Right Choice for Your Application

Your decision should be driven by the specific demands of your operating environment and the total cost of ownership, not just the initial price of the seal.

- If your primary focus is cost-effectiveness in a standard application: A traditional elastomeric O-ring (like Nitrile or Viton) is almost always the correct and most economical choice.

- If your primary focus is sealing against aggressive chemicals or wide temperature swings: An FEP encapsulated O-ring provides the necessary protection while balancing performance with cost.

- If your primary focus is preventing contamination in food or pharmaceutical processes: The FDA and USP Class VI compliant materials used in encapsulated O-rings ensure purity.

- If your primary focus is a critical, long-term static seal in a harsh environment: The low compression set and chemical inertness of an encapsulated O-ring ensure maximum reliability.

By matching the seal's properties to the application's demands, you ensure both the performance and longevity of your equipment.

Summary Table:

| Feature | Encapsulated O-Rings (FEP/PTFE) | Traditional Elastomeric O-Rings |

|---|---|---|

| Chemical Resistance | Excellent (Near-universal) | Limited (Material-specific) |

| Temperature Range | Wide (e.g., -60°C to 205°C) | Narrower |

| Flexibility / Compression | Good (from elastomeric core) | Excellent |

| Coefficient of Friction | Very Low | Higher |

| Compression Set | Low | Varies |

| Cost | Higher Initial Cost | Lower Initial Cost |

| Installation | Sensitive (requires care) | Forgiving |

Need a reliable seal for aggressive chemicals, extreme temperatures, or high-purity applications?

KINTEK specializes in manufacturing high-performance PTFE components, including custom encapsulated O-rings. We combine precision production with expert material science to deliver seals that protect your equipment and extend its service life in the most demanding semiconductor, medical, laboratory, and industrial environments.

From prototypes to high-volume orders, we provide the custom fabrication support you need. Contact KINTEK today to discuss your specific sealing challenge and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications