In Direct-to-Garment (DTG) printing, a Teflon sheet is used as a protective cover placed between the printed garment and the heat press during the final curing stage. Its primary functions are to ensure the ink cures properly by distributing heat evenly and to protect both the garment and the heat press from damage. This simple tool prevents scorching, eliminates ink transfer, and helps produce a smooth, professional finish.

A Teflon sheet is more than just a protective layer in DTG printing; it is a critical tool for process control. It guarantees consistent heat application for proper ink curing while safeguarding the garment and your heat press from damage.

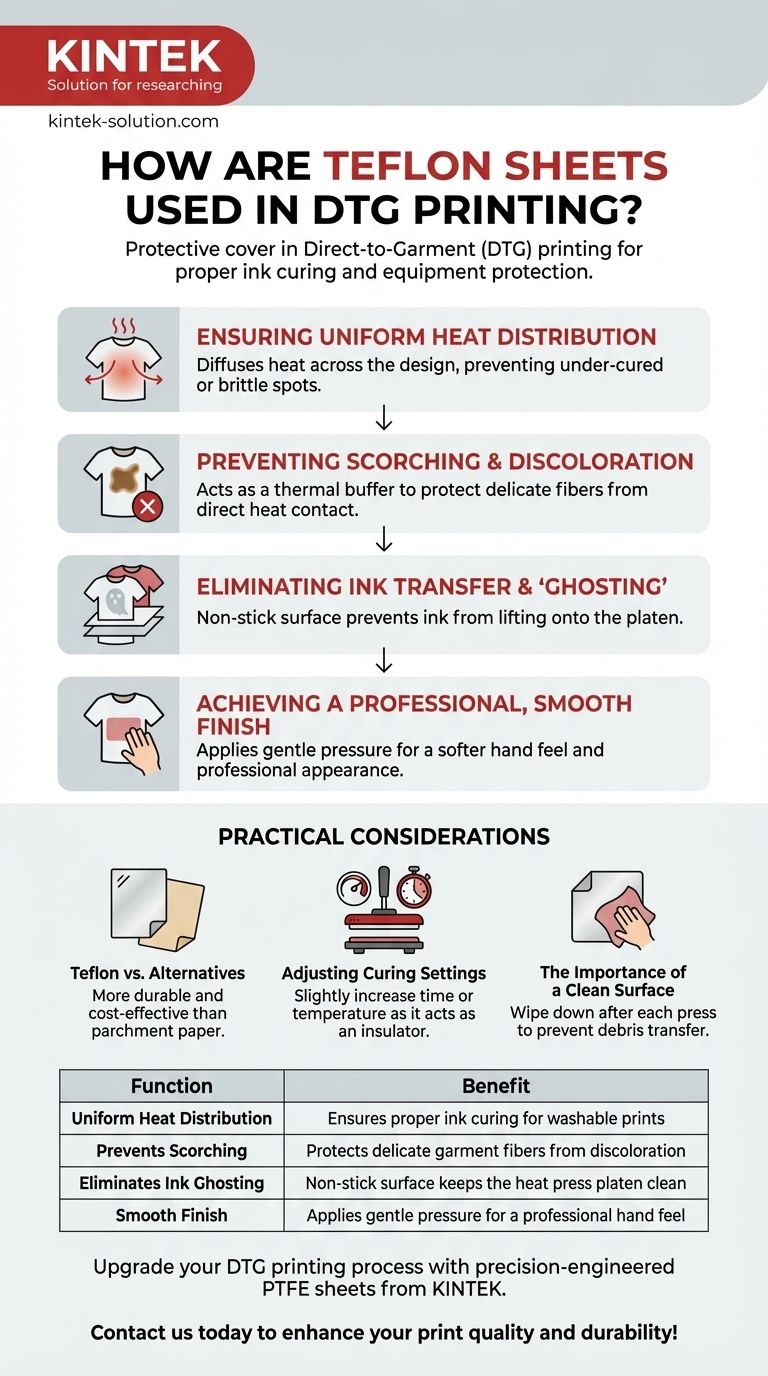

The Core Functions of a Teflon Sheet in DTG Curing

To understand why a Teflon sheet is essential, we need to look at the problems it solves during the heat-curing process, which permanently bonds the water-based DTG ink to the fabric fibers.

Ensuring Uniform Heat Distribution

The heating elements within a press platen can create subtle hot spots. A Teflon sheet acts as a diffuser, evening out the heat distribution across the entire surface of the design.

This uniform heat is critical for proper ink curing. Inconsistent temperatures can lead to under-cured areas that wash out prematurely or over-cured spots where the ink and fabric become brittle.

Preventing Garment Scorching and Discoloration

Direct contact with a hot metal platen can easily scorch or yellow certain fabrics, especially light-colored cotton and synthetic blends.

The Teflon sheet provides a thermal buffer. It moderates the intensity of the heat transfer, protecting the delicate garment fibers from direct, harsh contact and significantly reducing the risk of discoloration.

Eliminating Ink Transfer and "Ghosting"

During curing, it's possible for a small amount of ink to lift from the garment and adhere to the hot upper platen of the heat press.

This residue can then transfer onto the next garment you press, creating a faint, unwanted image known as "ghosting." The non-stick surface of the Teflon sheet prevents ink from ever touching the platen, keeping your equipment clean and your prints sharp.

Achieving a Professional, Smooth Finish

The sheet applies gentle, even pressure that helps lay down the garment fibers and press the ink smoothly into the fabric. This process results in a print with a softer "hand" (the way it feels to the touch) and a more integrated, professional appearance.

Understanding the Practical Considerations

While highly effective, incorporating a Teflon sheet requires a few minor adjustments to your workflow for optimal results.

Teflon vs. Alternatives

Parchment paper can be used as a disposable alternative. However, Teflon is far more durable and cost-effective over time due to its reusability. It also imparts a slightly different, smoother finish compared to the more matte texture left by parchment.

Adjusting Your Curing Settings

Because the Teflon sheet adds a layer between the heat source and the ink, it acts as a slight insulator. You may need to marginally increase your curing time or temperature (e.g., by 5-10 seconds or degrees) to ensure the ink reaches the required curing threshold. Always perform a wash test on a sample to dial in your settings.

The Importance of a Clean Surface

The Teflon sheet must be kept clean. After each press, quickly wipe it down to remove any potential ink residue or lint. A dirty sheet can transfer old ink or debris onto your next print, defeating one of its primary purposes.

Making the Right Choice for Your Goal

Integrating a Teflon sheet is a simple, low-cost step that pays significant dividends in quality and consistency.

- If your primary focus is print longevity and washability: Use a Teflon sheet to guarantee the ink is fully and evenly cured, which is the single most important factor for durability.

- If your primary focus is protecting your equipment investment: A Teflon sheet is non-negotiable for preventing ink buildup on your heat press platen, saving you cleaning time and costly replacements.

- If your primary focus is achieving a consistent, high-quality finish: The sheet standardizes the final look of your prints by controlling heat and pressure uniformly across every garment.

Incorporating a Teflon sheet into your process is a simple step that elevates your DTG results from acceptable to professional.

Summary Table:

| Function | Benefit |

|---|---|

| Uniform Heat Distribution | Ensures proper ink curing for washable prints |

| Prevents Scorching | Protects delicate garment fibers from discoloration |

| Eliminates Ink Ghosting | Non-stick surface keeps the heat press platen clean |

| Smooth Finish | Applies gentle pressure for a professional hand feel |

Upgrade your DTG printing process with precision-engineered PTFE sheets from KINTEK.

Our high-quality Teflon sheets are manufactured to provide the consistent, non-stick surface you need to protect your garments and equipment while achieving a superior finish. Whether you're running a small shop or a large-scale operation, we offer custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Contact us today to discuss how our PTFE components can enhance your print quality and durability!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability