Teflon, technically known as Polytetrafluoroethylene (PTFE), is a high-performance fluoropolymer used across a remarkably diverse set of industries. Its most common applications are found in aerospace, chemical processing, medical, electronics, and automotive sectors due to its unique combination of properties that solve critical engineering challenges.

The core reason for Teflon's widespread adoption is not a single feature, but its powerful combination of properties: it is nearly impervious to chemical attack, stable across extreme temperatures, and possesses one of the lowest coefficients of friction of any solid material. This versatility makes it an essential problem-solver in environments where other materials would quickly fail.

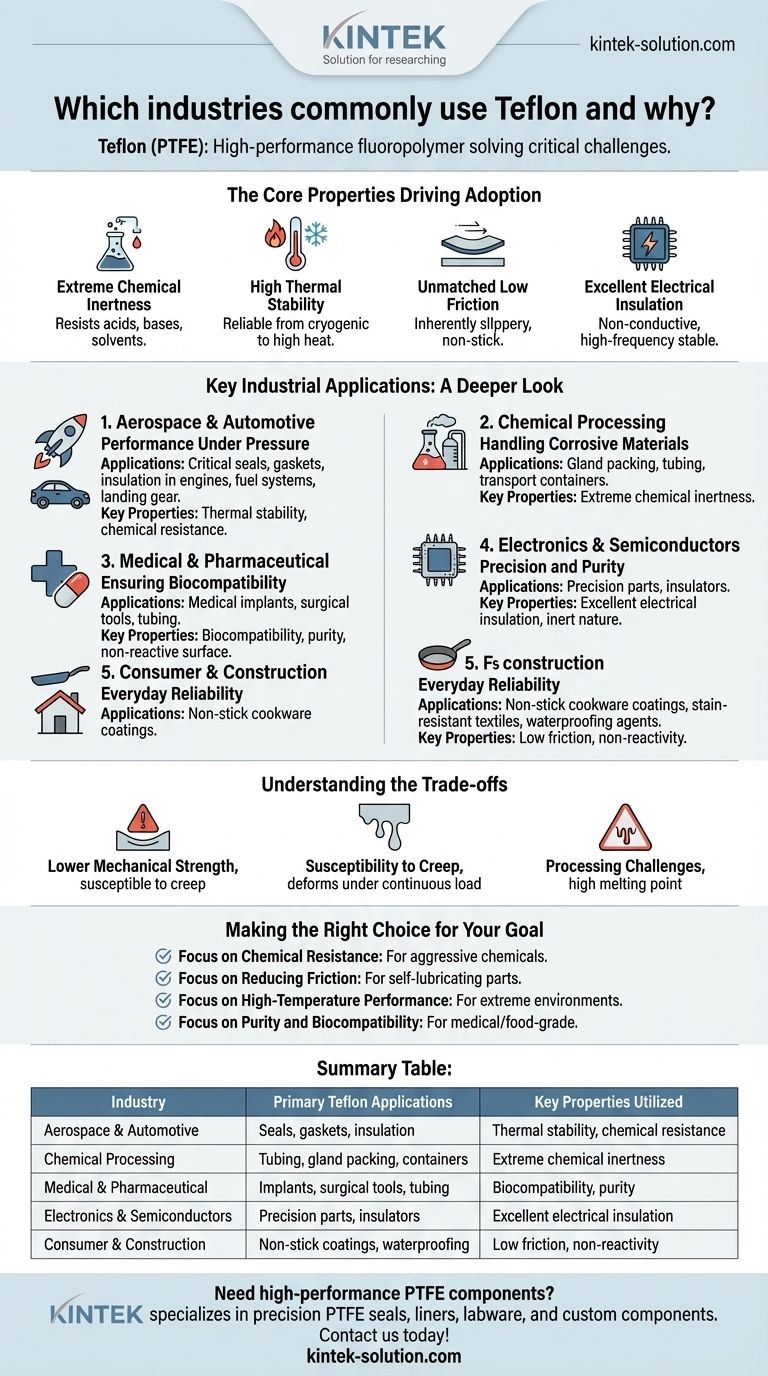

The Core Properties Driving Adoption

To understand why Teflon is so ubiquitous, we must first look at its fundamental characteristics. These properties are the reason engineers in demanding fields consistently specify it for critical components.

Extreme Chemical Inertness

Teflon is exceptionally non-reactive. It resists corrosion and degradation from the most aggressive acids, bases, and solvents.

This makes it the material of choice for containing or transporting harsh chemicals where purity and safety are paramount.

High Thermal Stability

Teflon performs reliably across a vast temperature range. It maintains its structural integrity and properties in environments from cryogenic lows to high-heat applications.

This thermal resilience is critical for components used in engines, industrial processing, and aerospace systems.

Unmatched Low Friction

Famously known for its non-stick quality, Teflon has an extremely low coefficient of friction. This "slipperiness" is inherent to the material itself.

This property is invaluable for creating self-lubricating bearings, non-stick coatings, and surfaces that prevent material buildup.

Excellent Electrical Insulation

Teflon is an outstanding electrical insulator, meaning it does not conduct electricity. It maintains this property even at high frequencies and temperatures.

This makes it a vital material for insulating wires, cables, and sensitive components in electronics and semiconductor manufacturing.

Key Industrial Applications: A Deeper Look

Different industries leverage specific Teflon properties to solve their unique challenges.

Aerospace & Automotive: Performance Under Pressure

In these sectors, components must withstand extreme temperatures, high pressure, and exposure to fuels and hydraulic fluids.

Teflon is used for critical seals, gaskets, and insulation in engines, fuel systems, and landing gear. Its thermal stability and chemical resistance ensure reliability and prevent leaks in harsh operating conditions.

Chemical Processing: Handling Corrosive Materials

The chemical industry relies on materials that can safely manage highly corrosive substances without degrading.

Teflon's chemical inertness makes it ideal for gland packing, tubing, and transport containers. It ensures the integrity of the process and the purity of the materials being handled.

Medical & Pharmaceutical: Ensuring Biocompatibility

Purity and non-reactivity are non-negotiable in medical applications to ensure patient safety.

Because Teflon is inert and biocompatible, it is used for medical implants, surgical tools, and tubing. Its clean, non-reactive surface does not trigger adverse reactions within the body.

Electronics & Semiconductors: Precision and Purity

Manufacturing semiconductors and electronics requires materials that are both excellent insulators and extremely pure to avoid contamination.

Teflon is machined into precision parts and insulators for this industry. Its electrical properties prevent interference, and its inert nature ensures it doesn't contaminate the pristine manufacturing environment.

Consumer & Construction: Everyday Reliability

Teflon's properties also translate to common household and industrial applications.

It serves as the non-stick coating on cookware, a stain-resistant treatment for textiles and fabrics, and a waterproofing agent in construction, all thanks to its low-friction, non-reactive surface.

Understanding the Trade-offs

No material is perfect, and relying on Teflon requires an understanding of its limitations. Being aware of these trade-offs is crucial for proper material selection.

Lower Mechanical Strength

Compared to metals and some engineering plastics, Teflon is relatively soft and has lower tensile strength and rigidity. It is not suitable for high-load structural applications on its own.

Susceptibility to Creep

Under a continuous load, especially at elevated temperatures, Teflon can slowly deform over time. This phenomenon, known as "creep," must be accounted for in component design.

Processing Challenges

Teflon's high melting point and viscosity make it more difficult to process than common plastics like polyethylene or polypropylene. This can increase manufacturing complexity and cost.

Making the Right Choice for Your Goal

Selecting Teflon is about matching its unique strengths to a specific engineering problem.

- If your primary focus is chemical resistance: Teflon is an elite choice for handling aggressive chemicals where other polymers would corrode or degrade.

- If your primary focus is reducing friction: Its inherently low friction is ideal for creating self-lubricating mechanical parts and non-stick surfaces.

- If your primary focus is high-temperature performance: It maintains its properties and integrity in environments that would melt or destroy many other materials.

- If your primary focus is purity and biocompatibility: Its inertness makes it a safe and reliable option for medical, pharmaceutical, and food-grade applications.

Understanding these core strengths is the key to leveraging Teflon's remarkable capabilities in any industrial application.

Summary Table:

| Industry | Primary Teflon Applications | Key Properties Utilized |

|---|---|---|

| Aerospace & Automotive | Seals, gaskets, insulation | Thermal stability, chemical resistance |

| Chemical Processing | Tubing, gland packing, containers | Extreme chemical inertness |

| Medical & Pharmaceutical | Implants, surgical tools, tubing | Biocompatibility, purity |

| Electronics & Semiconductors | Precision parts, insulators | Excellent electrical insulation |

| Consumer & Construction | Non-stick coatings, waterproofing | Low friction, non-reactivity |

Need high-performance PTFE components for your industry? KINTEK specializes in manufacturing precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders, ensuring your parts meet the exacting demands of chemical resistance, thermal stability, and purity. Contact us today to discuss your specific application and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is the melting point of PTFE? Master Its Thermal Limits for Better Performance

- What are the challenges in processing PTFE? Overcoming High Melt Viscosity and Machining Difficulties

- What is expanded PTFE and what are its key properties? A Guide to the Microporous Wonder Material

- What are some key properties of PTFE coatings? Master Non-Stick, Chemical & Thermal Resistance

- What is PTFE and why is it significant? Unlock the Power of a High-Performance Polymer

- What are the basic chemical properties of PTFE? Unlocking Extreme Chemical Resistance and Non-Stick Performance

- What is the tensile strength range of PTFE? Understanding Its Mechanical Limits for Your Design

- What industrial applications does PTFE have? Unlock Performance in Extreme Environments