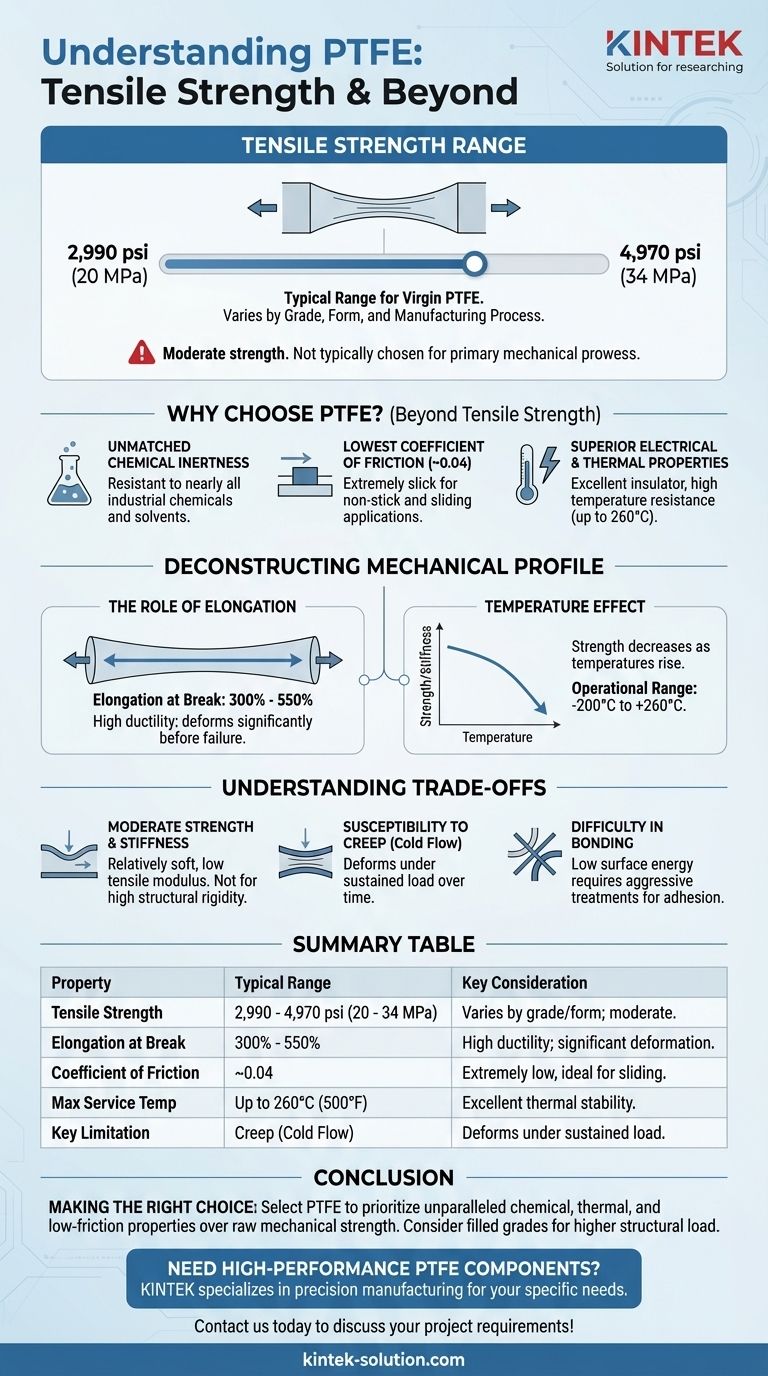

As a raw material, Polytetrafluoroethylene (PTFE) exhibits a tensile strength that typically ranges from 2,990 to 4,970 psi (approximately 20 to 34 MPa). The exact value within this range depends heavily on the specific grade of the material, its form factor (like a sheet, rod, or O-ring), and the manufacturing process used.

While its tensile strength is a key data point, PTFE is rarely chosen for its mechanical prowess. Instead, its selection is almost always driven by its extraordinary combination of chemical inertness, thermal stability, and an extremely low coefficient of friction.

Deconstructing PTFE's Mechanical Profile

Understanding the tensile strength of PTFE requires looking beyond a single number. Its behavior under load is fundamentally linked to other properties that define its performance in real-world applications.

The Meaning of the Tensile Strength Range

The broad range of 2,990 to 4,970 psi exists because "PTFE" is not a single, uniform material. Factors like the specific resin used, whether it's molded or extruded, and its final form (e.g., O-rings often have a narrower range of 3,625 to 4,496 psi) all influence its final mechanical properties.

The Critical Role of Elongation

Tensile strength only tells you the force required to break the material. Elongation at break, which for PTFE can be very high (300-550%), tells you how much the material will stretch before it fails. This high elongation means PTFE is a ductile, not brittle, material; it deforms significantly rather than snapping.

How Temperature Affects Performance

PTFE is famous for its wide operational temperature range, from as low as -200°C up to +260°C. However, its mechanical properties, including tensile strength, are not constant across this range. Strength and stiffness decrease as temperatures rise.

Why Tensile Strength Isn't the Main Story

Engineers and designers specify PTFE for its unique characteristics that other materials cannot match. Its moderate strength is often a secondary consideration to these primary benefits.

Unmatched Chemical Inertness

PTFE is virtually inert and resistant to almost all industrial chemicals and solvents. This makes it an essential material for seals, gaskets, and linings in corrosive environments where material degradation is the primary concern.

The Lowest Coefficient of Friction

With a dynamic coefficient of friction as low as 0.04, PTFE has one of the slickest surfaces of any known solid. This property makes it the default choice for non-stick coatings, low-friction bearings, and sliding applications where lubricity is paramount.

Superior Electrical and Thermal Properties

PTFE is an excellent electrical insulator with a high dielectric strength (19.7 kV/mm). This, combined with its ability to withstand high temperatures, makes it invaluable for high-frequency electronics and wire insulation.

Understanding the Trade-offs

To use PTFE effectively, you must be aware of its inherent limitations. Its unique strengths come with corresponding weaknesses that are critical for design consideration.

Moderate Strength and Stiffness

Compared to other engineering plastics like PEEK or Nylon, virgin PTFE is a relatively soft and flexible material. Its tensile modulus (a measure of stiffness) is low, meaning it is not suitable for applications requiring high structural rigidity on its own.

Susceptibility to Creep (Cold Flow)

Under a sustained compressive load, PTFE has a tendency to deform permanently over time. This phenomenon, known as creep or cold flow, is a significant design limitation, especially for seals and gaskets that are under constant pressure.

Difficulty in Bonding

The same low surface energy (18 Dynes/g) that gives PTFE its non-stick properties also makes it very difficult to bond to other materials. Adhesion requires aggressive chemical or plasma surface treatments, adding complexity and cost to assemblies.

Making the Right Choice for Your Application

Selecting the right material requires aligning its properties with your primary engineering goal.

- If your primary focus is low-friction movement or sealing: PTFE is an exceptional choice where its lubricity and chemical resistance are paramount, and the mechanical loads are relatively low.

- If your primary focus is resisting corrosive chemicals or extreme temperatures: PTFE is a top-tier performer, providing stability where most other plastics would fail, making its moderate strength acceptable.

- If your primary focus is high structural load-bearing: You should evaluate filled grades of PTFE (like glass or carbon-filled) or consider alternative high-strength polymers, as virgin PTFE will likely deform.

Ultimately, selecting PTFE is a decision to prioritize its unparalleled chemical, thermal, and low-friction properties over raw mechanical strength.

Summary Table:

| Property | Typical Range for PTFE | Key Consideration |

|---|---|---|

| Tensile Strength | 2,990 - 4,970 psi (20 - 34 MPa) | Varies by grade and form; moderate compared to other plastics |

| Elongation at Break | 300% - 550% | High ductility; deforms significantly before failure |

| Coefficient of Friction | ~0.04 | Extremely low, ideal for non-stick and sliding applications |

| Maximum Service Temperature | Up to 260°C (500°F) | Excellent thermal stability, but strength decreases with heat |

| Key Limitation | Creep (Cold Flow) | Deforms under sustained load; critical for seals and gaskets |

Need high-performance PTFE components that balance strength with unmatched chemical and thermal resistance?

At KINTEK, we specialize in precision manufacturing of PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise ensures your parts meet exact specifications while leveraging PTFE's full benefits—chemical inertness, low friction, and extreme temperature stability.

Contact us today to discuss your project requirements and get a custom solution tailored to your needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- How is PTFE used in industrial processes? Maximize Safety and Efficiency