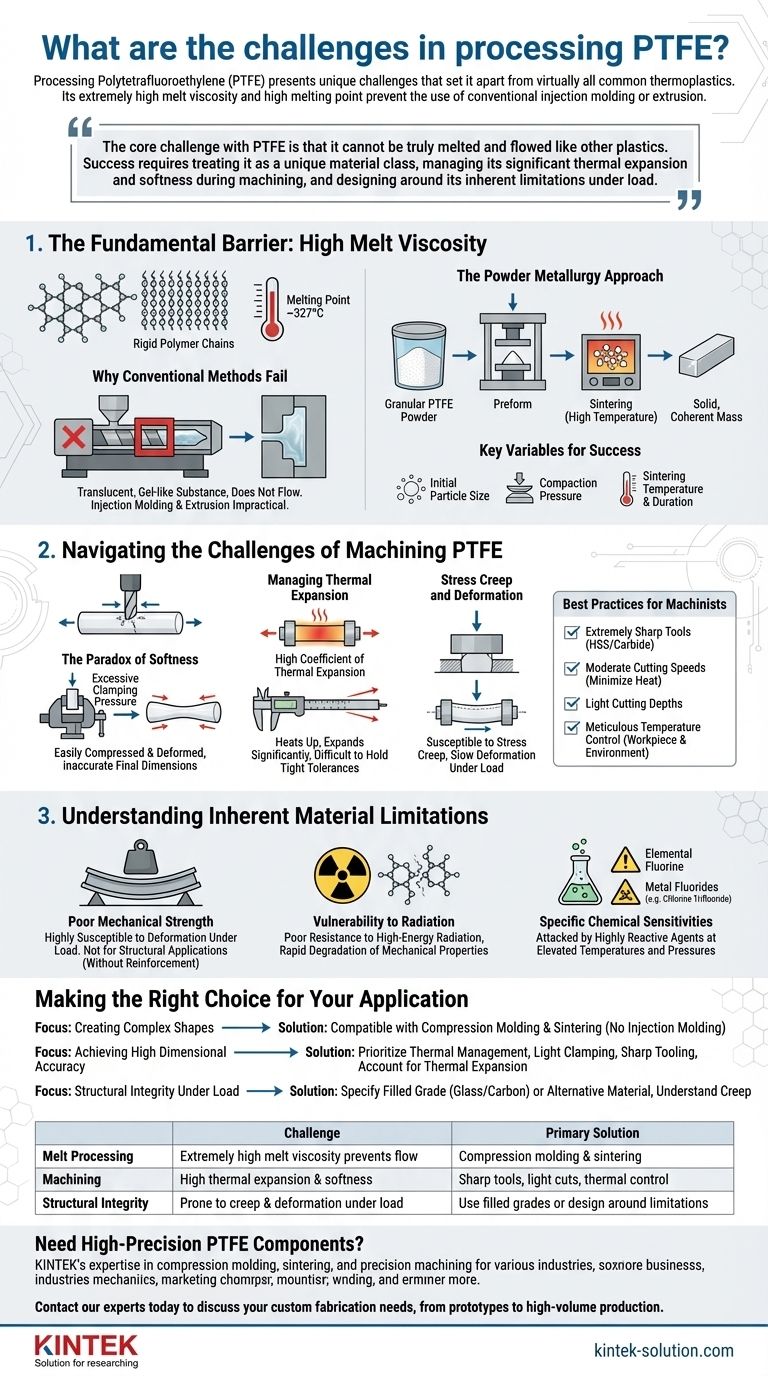

Processing Polytetrafluoroethylene (PTFE) presents unique challenges that set it apart from virtually all common thermoplastics. Its extremely high melt viscosity and high melting point prevent the use of conventional injection molding or extrusion. This forces a reliance on specialized techniques like compression molding and sintering, which are more similar to powder metallurgy than traditional polymer processing.

The core challenge with PTFE is that it cannot be truly melted and flowed like other plastics. Success requires treating it as a unique material class, managing its significant thermal expansion and softness during machining, and designing around its inherent limitations under load.

The Fundamental Barrier: High Melt Viscosity

The most significant hurdle in processing PTFE stems from its molecular structure. The rigid polymer chains result in an exceptionally high viscosity even when heated past its melting point of approximately 327°C.

Why Conventional Methods Fail

Unlike plastics like polypropylene or polycarbonate, PTFE does not transition to a liquid state that can be easily pushed into a mold. Instead, it becomes a translucent, gel-like substance that does not flow.

This behavior makes standard injection molding and extrusion impractical for pure PTFE.

The Powder Metallurgy Approach

Processing PTFE requires a multi-step method. It begins with compressing granular PTFE powder into a desired shape, known as a preform.

This preform is then heated in a process called sintering. The part is held at a high temperature, allowing the individual polymer particles to fuse together into a solid, coherent mass.

Key Variables for Success

The final mechanical properties of a sintered PTFE part are not guaranteed. They depend heavily on three factors: the initial particle size of the powder, the compaction pressure used to create the preform, and the precise sintering temperature and duration.

Navigating the Challenges of Machining PTFE

Once a stock shape (like a rod or sheet) is formed, PTFE is often machined to its final dimensions. While it is soft and easy to cut, achieving precision is difficult.

The Paradox of Softness

PTFE’s softness makes cutting effortless, but it also means the material can be easily compressed and deformed. Excessive clamping pressure in a vise or chuck will distort the workpiece, leading to inaccurate final dimensions once the pressure is released.

Managing Thermal Expansion

PTFE has a very high coefficient of thermal expansion. As it heats up from the friction of machining, it expands significantly, which can throw off measurements and make holding tight tolerances exceptionally challenging.

Stress Creep and Deformation

Even under moderate, constant pressure, PTFE is susceptible to stress creep, meaning it will slowly deform over time. This must be considered in the design of any component that will be under a sustained load.

Best Practices for Machinists

To achieve good results, use extremely sharp tools (HSS or carbide), moderate cutting speeds to minimize heat buildup, and light cutting depths. Meticulous control over the temperature of the workpiece and environment is essential for precision.

Understanding Inherent Material Limitations

Beyond melt and machining issues, PTFE has inherent properties that act as processing and design constraints. These must be understood to avoid application failure.

Poor Mechanical Strength

Unfilled, or "virgin," PTFE lacks sturdiness and is highly susceptible to deformation under load. It is an excellent material for low-friction surfaces but is not suitable for most structural or load-bearing applications without reinforcement (e.g., glass or carbon fillers).

Vulnerability to Radiation

PTFE has poor resistance to high-energy radiation. Exposure can cause the polymer chains to break down, leading to a rapid degradation of its mechanical properties.

Specific Chemical Sensitivities

While famous for its chemical inertness, PTFE is not invincible. It can be attacked by highly reactive agents like elemental fluorine and certain metal fluorides (such as chlorine trifluoride), especially at elevated temperatures and pressures.

Making the Right Choice for Your Application

- If your primary focus is creating complex shapes: Recognize that you cannot use injection molding and must design parts that are compatible with compression molding and sintering processes.

- If your primary focus is achieving high dimensional accuracy: Prioritize thermal management, light clamping forces, and extremely sharp tooling during machining, and account for thermal expansion in your design tolerances.

- If your primary focus is structural integrity under load: Understand that unfilled PTFE is prone to creep; specify a filled grade or choose an alternative material for any significant load-bearing role.

By respecting PTFE's unique properties instead of fighting them, you can successfully harness its exceptional performance for your most demanding applications.

Summary Table:

| Challenge | Key Issue | Primary Solution |

|---|---|---|

| Melt Processing | Extremely high melt viscosity prevents flow | Compression molding & sintering |

| Machining | High thermal expansion & softness | Sharp tools, light cuts, thermal control |

| Structural Integrity | Prone to creep & deformation under load | Use filled grades or design around limitations |

Need High-Precision PTFE Components?

Successfully navigating the challenges of PTFE processing requires specialized expertise. At KINTEK, we manufacture precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, and industrial sectors. Our mastery of compression molding, sintering, and precision machining ensures your parts meet the strictest tolerances and performance requirements.

Let us handle the complexities so you can leverage PTFE's unique properties. Contact our experts today to discuss your custom fabrication needs, from prototypes to high-volume production.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications