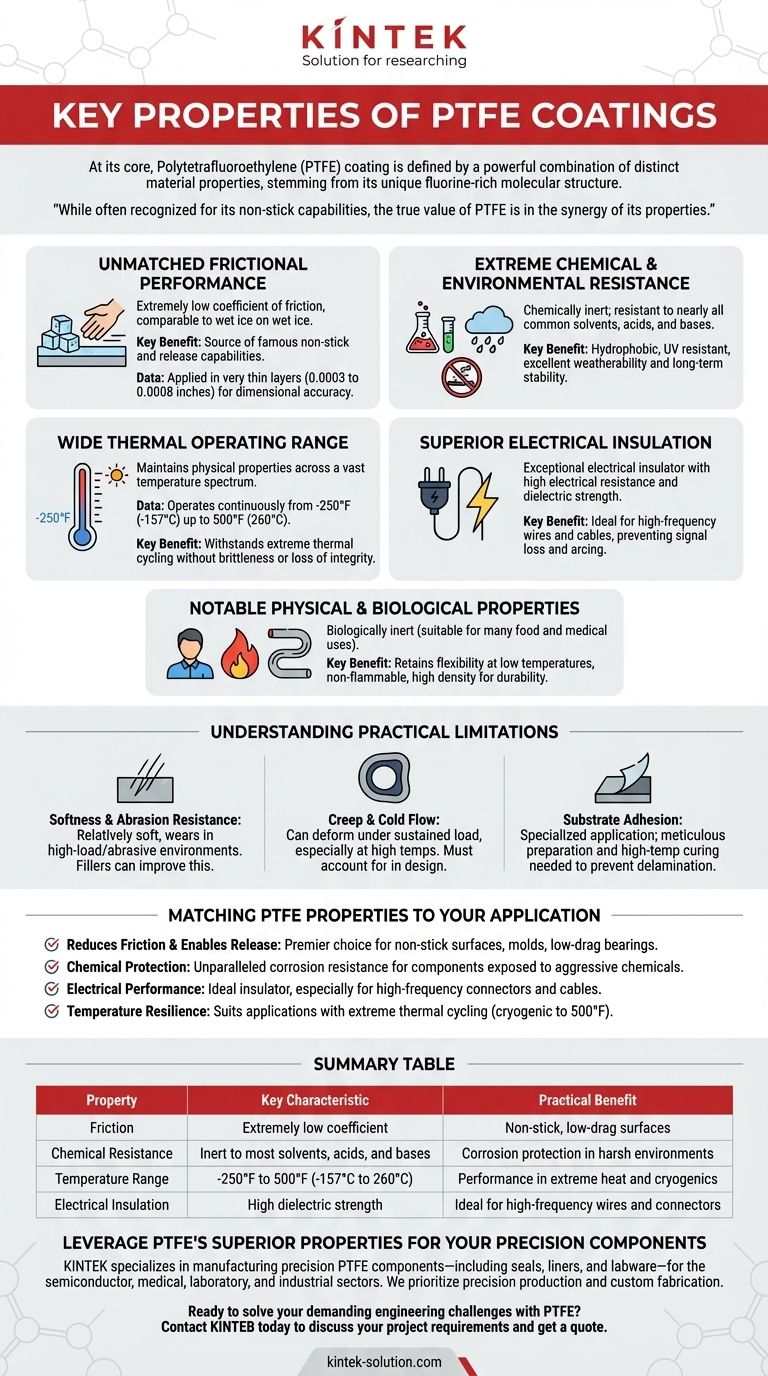

At its core, a Polytetrafluoroethylene (PTFE) coating is defined by a powerful combination of distinct material properties. These include an exceptionally low coefficient of friction, outstanding chemical inertness, a very wide operating temperature range, and excellent electrical insulation. These attributes stem from its unique molecular structure, which is rich in fluorine.

While often recognized for its non-stick capabilities, the true value of PTFE is in the synergy of its properties. Understanding how its thermal stability, chemical resistance, and low-friction surface intersect is the key to leveraging it for the correct high-performance industrial, electrical, or mechanical application.

A Breakdown of PTFE's Core Attributes

To select PTFE, you must understand how its individual characteristics translate into real-world performance. Each property serves a specific engineering function.

Unmatched Frictional Performance

PTFE has one of the lowest coefficients of friction of any known solid, comparable to wet ice on wet ice. This is the source of its famous non-stick and release capabilities.

Coatings are typically applied in very thin layers, often between 0.0003 and 0.0008 inches, ensuring dimensional accuracy while providing a highly effective low-friction surface.

Extreme Chemical and Environmental Resistance

PTFE is chemically inert, meaning it is nonreactive and resistant to corrosion from nearly all common solvents, acids, and bases, even at elevated temperatures.

It is also hydrophobic, actively repelling water, and does not absorb moisture. This, combined with its resistance to UV radiation, gives it excellent weatherability and long-term stability in harsh environments.

Wide Thermal Operating Range

A key advantage of PTFE is its ability to maintain its physical properties across a vast temperature spectrum.

It can operate continuously at temperatures as high as 500°F (260°C) and can withstand cryogenic temperatures as low as -250°F (-157°C) without becoming brittle or losing integrity.

Superior Electrical Insulation

PTFE is an exceptional electrical insulator with very high electrical resistance and dielectric strength. It effectively blocks the flow of electricity.

This makes it an ideal material for insulating high-frequency wires and cables, as it prevents signal loss and electrical arcing.

Notable Physical and Biological Properties

Beyond its primary attributes, PTFE is also biologically inert, making it suitable for many food processing and medical applications under normal use conditions.

It also retains its flexibility at low temperatures, is non-flammable, and has a high density for a polymer, contributing to its overall durability.

Understanding the Practical Limitations

No material is perfect. Acknowledging PTFE's trade-offs is critical for proper application and avoiding premature failure.

Softness and Abrasion Resistance

PTFE is a relatively soft material. In its pure form, it is not well-suited for high-load or abrasive environments where it can wear away quickly. Fillers like glass or carbon can be added to improve wear resistance, but this can alter other properties.

Creep and Cold Flow

Under a sustained load, especially at higher temperatures, PTFE can slowly deform or "creep." This must be accounted for in the design of structural components or tight-tolerance seals.

Substrate Adhesion

Applying a PTFE coating is a specialized process. The substrate surface must be meticulously prepared and the coating cured at high temperatures to achieve a durable bond. Poor application can lead to delamination and coating failure.

Matching PTFE Properties to Your Application

Your end goal determines which of PTFE's properties is most valuable. Use this guide to make your decision.

- If your primary focus is reducing friction and enabling release: PTFE's exceptionally low coefficient of friction makes it the premier choice for non-stick surfaces, molds, and low-drag bearings.

- If your primary focus is chemical protection: Its near-total chemical inertness provides unparalleled corrosion resistance for components exposed to aggressive acids, bases, and solvents.

- If your primary focus is electrical performance: Its high dielectric strength and low dissipation factor make it an ideal insulator, especially for high-frequency connectors and cables.

- If your primary focus is temperature resilience: Its ability to perform reliably from cryogenic conditions up to 500°F (260°C) suits applications with extreme thermal cycling.

By understanding this unique combination of attributes, you can confidently leverage PTFE to solve your most demanding engineering challenges.

Summary Table:

| Property | Key Characteristic | Practical Benefit |

|---|---|---|

| Friction | Extremely low coefficient | Non-stick, low-drag surfaces |

| Chemical Resistance | Inert to most solvents, acids, and bases | Corrosion protection in harsh environments |

| Temperature Range | -250°F to 500°F (-157°C to 260°C) | Performance in extreme heat and cryogenics |

| Electrical Insulation | High dielectric strength | Ideal for high-frequency wires and connectors |

Leverage PTFE's Superior Properties for Your Precision Components

Understanding the synergy of PTFE's properties is the first step. Implementing them in a high-quality, custom-fabricated component is the next. KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring your parts meet exact specifications for friction, chemical resistance, and thermal stability.

Ready to solve your demanding engineering challenges with PTFE? Contact KINTEB today to discuss your project requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

People Also Ask

- What are the mechanical properties of FR4 PCB material? Understanding Rigidity, Thermal Limits & Cost

- What maintenance practices ensure optimal PTFE performance? Preserve Performance with Proven Care

- How does PTFE perform as an electrical insulator? Unmatched Signal Integrity & High-Voltage Reliability

- What was the key finding about Teflon's friction mechanism? Unlocking the Secret of Its Self-Lubricating Slipperiness

- What are some common household uses of Teflon? Discover the Material Science in Your Home

- What is a disadvantage of PTFE in terms of mechanical strength? Overcome Its Weakness with Reinforced Solutions

- What makes PTFE coatings unique in terms of their chemical makeup? The Power of the Carbon-Fluorine Bond

- What are some common uses of PTFE? Unlock Extreme Performance for Your Industry