At its core, Polytetrafluoroethylene (PTFE) is defined by a remarkable set of chemical properties. It is exceptionally non-reactive, thermally stable over a wide range of temperatures, and highly resistant to water and oils. These characteristics all stem from its unique molecular structure, which consists of a carbon backbone completely shielded by a dense sheath of fluorine atoms.

The key to understanding PTFE is recognizing the immense strength of the carbon-fluorine bond. This single structural feature is the origin of nearly all its valuable properties, from its chemical inertness and high melting point to its famous non-stick surface.

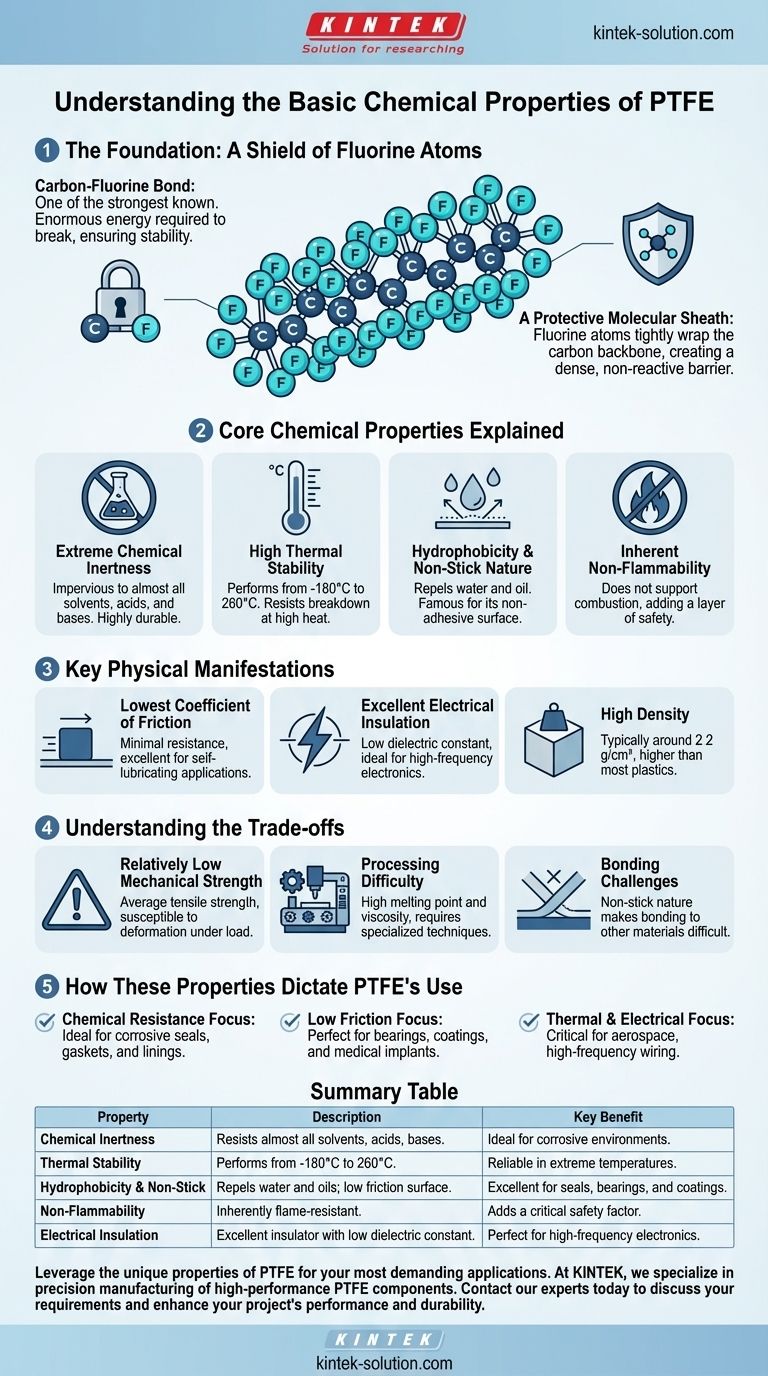

The Foundation: A Shield of Fluorine Atoms

The chemical behavior of PTFE is a direct result of its atomic makeup. Understanding this structure is the first step to appreciating its capabilities.

The Carbon-Fluorine Bond

The bond between carbon and fluorine atoms is one of the strongest known in organic chemistry. A tremendous amount of energy is required to break it, which is the primary reason for PTFE's stability.

A Protective Molecular Sheath

PTFE's structure consists of a long chain of carbon atoms tightly bonded to each other. More importantly, each carbon atom is also bonded to two fluorine atoms, which effectively wrap around the carbon chain, creating a dense, non-reactive protective sheath.

Core Chemical Properties Explained

This unique molecular architecture gives rise to a set of highly desirable chemical properties that make PTFE useful in demanding applications.

Extreme Chemical Inertness

Because of the strong C-F bonds and the protective fluorine sheath, PTFE is virtually impervious to chemical attack. It does not react with almost any common solvents, acids, or bases, making it one of the most durable plastics available.

High Thermal Stability

The energy required to break the C-F bonds means PTFE can withstand a very broad range of temperatures. It maintains its properties from cryogenic conditions (-180°C / -292°F) up to high-heat applications (260°C / 500°F), with a melting point around 327°C (621°F).

Hydrophobicity and Non-Stick Nature

Fluorine is the most electronegative element, meaning it strongly repels other molecules, including water and oil. This makes PTFE’s surface hydrophobic (water-repelling) and is the source of its famous non-stick, or non-adhesive, quality.

Inherent Non-Flammability

The stable chemical structure of PTFE makes it inherently resistant to combustion. It will not support a flame, adding a critical layer of safety to its applications.

Key Physical Manifestations

These chemical properties directly influence the material's physical behavior, leading to several other well-known characteristics.

Lowest Coefficient of Friction

The non-reactive fluorine sheath creates a surface with extremely low intermolecular forces. This means other substances slide off it with minimal resistance, giving PTFE one of the lowest coefficients of friction of any known solid material.

Excellent Electrical Insulation

The electrons in the carbon-fluorine bonds are held very tightly, preventing the flow of electricity. This makes PTFE an outstanding electrical insulator with a low dielectric constant, ideal for high-frequency electronics.

High Density

The presence of heavy fluorine atoms gives PTFE a high density compared to many other plastics, typically around 2.2 g/cm³.

Understanding the Trade-offs

No material is perfect, and PTFE's unique properties come with certain limitations that are important to understand.

Relatively Low Mechanical Strength

While PTFE is durable and flexible, it is a relatively soft material. It has only average tensile strength and can be susceptible to "creep" or deformation under a sustained load.

Processing Difficulty

The same thermal stability that makes PTFE so useful also makes it difficult to process. Its high melting point and high melt viscosity mean it cannot be processed using conventional techniques like injection molding.

Bonding Challenges

The non-stick surface that is so valuable for cookware and bearings also makes it extremely difficult to bond PTFE to other surfaces. Adhering PTFE to another material typically requires specialized and aggressive surface treatments like chemical etching.

How These Properties Dictate PTFE's Use

Your choice to use PTFE should be driven by its unique combination of strengths.

- If your primary focus is chemical resistance: PTFE is the benchmark material for seals, gaskets, and linings used to handle highly corrosive chemicals.

- If your primary focus is low friction: Its non-stick, self-lubricating nature makes it ideal for high-performance bearings, non-stick coatings, and medical implants.

- If your primary focus is temperature stability or electrical insulation: PTFE is a critical component in aerospace, high-frequency wiring, and other demanding thermal or electrical environments.

Ultimately, PTFE is a powerful example of how a simple and stable molecular structure can produce a material with truly extraordinary capabilities.

Summary Table:

| Property | Description | Key Benefit |

|---|---|---|

| Chemical Inertness | Resists almost all solvents, acids, and bases. | Ideal for corrosive environments. |

| Thermal Stability | Performs from -180°C to 260°C. | Reliable in extreme temperatures. |

| Hydrophobicity & Non-Stick | Repels water and oils; low friction surface. | Excellent for seals, bearings, and coatings. |

| Non-Flammability | Inherently flame-resistant. | Adds a critical safety factor. |

| Electrical Insulation | Excellent insulator with low dielectric constant. | Perfect for high-frequency electronics. |

Leverage the unique properties of PTFE for your most demanding applications.

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a prototype or a high-volume order, our expertise ensures you get components that deliver unmatched chemical resistance, thermal stability, and reliability.

Contact our experts today to discuss your specific requirements and discover how our custom PTFE solutions can enhance your project's performance and durability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance