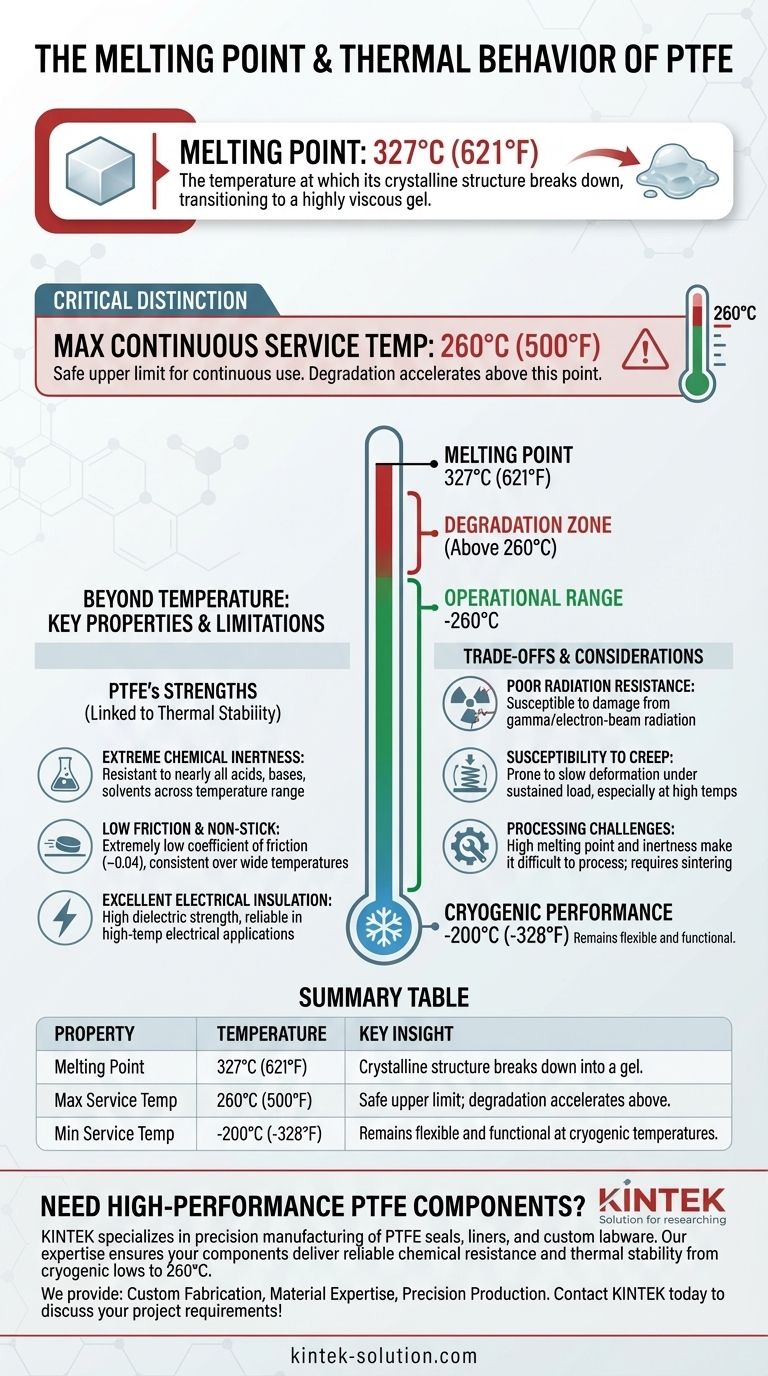

The melting point of PTFE is 327°C (621°F). This is the specific temperature at which its crystalline structure breaks down, transitioning it from a solid to a highly viscous gel-like state. However, for most engineering purposes, the more critical figure is its maximum continuous service temperature.

While PTFE's technical melting point is 327°C, its practical, safe upper limit for continuous use in most applications is significantly lower, around 260°C (500°F). Understanding this distinction is key to successfully applying the material.

Deconstructing PTFE's Thermal Behavior

To properly leverage Polytetrafluoroethylene (PTFE), one must look beyond a single data point. Its value comes from its performance across an exceptionally wide temperature range.

The Crystalline Melting Point

The official melting point of 327°C (621°F) represents the phase transition where the highly ordered crystalline regions of the polymer become disordered. Unlike many plastics that melt into a free-flowing liquid, PTFE becomes a translucent gel with extremely high viscosity, making it unsuitable for conventional melt processing like injection molding.

The Practical Service Temperature

The most important number for designers and engineers is the maximum continuous service temperature of 260°C (500°F). Above this temperature, PTFE begins to degrade at an accelerated rate, releasing potentially toxic fumes and losing its exceptional mechanical properties, even though it has not fully "melted."

Performance at Cryogenic Temperatures

PTFE's utility extends to extremely cold environments. It maintains its properties and does not become brittle even at cryogenic temperatures as low as -200°C (-328°F), a feat that few other polymers can achieve.

Why Temperature Range is Only Part of the Story

PTFE's thermal stability is intrinsically linked to the other properties that make it such a unique material. The strength of the carbon-fluorine bonds is responsible for its performance across the board.

Extreme Chemical Inertness

The same molecular stability that provides high heat resistance also makes PTFE resistant to nearly all acids, bases, and solvents. It maintains this chemical inertness across its entire functional temperature range.

Low Friction and Non-Stick Properties

PTFE is famous for its extremely low coefficient of friction (around 0.04) and non-stick surface. These characteristics remain remarkably consistent from cryogenic lows to its upper service temperature limit.

Excellent Electrical Insulation

PTFE is an outstanding electrical insulator with very high dielectric strength. Its thermal stability ensures it can perform reliably in high-temperature electrical applications without degrading or losing its insulating properties.

Understanding the Trade-offs and Limitations

No material is perfect. While PTFE excels in thermal stability and chemical resistance, it has notable weaknesses that must be considered for any application.

Poor Radiation Resistance

PTFE is susceptible to damage from high-energy radiation, such as gamma or electron-beam radiation. This exposure can break down the polymer's molecular chains, leading to a rapid loss of mechanical strength.

Susceptibility to Creep

Under sustained mechanical load, especially at elevated temperatures, PTFE is prone to creep, which is a slow, continuous deformation over time. This makes it unsuitable for high-load structural components without reinforcement.

Processing Challenges

The high melting point and chemical inertness that make PTFE so useful also make it difficult to process. It cannot be easily melt-processed, requiring specialized and often more costly manufacturing techniques like sintering.

Making the Right Choice for Your Application

Selecting the right material requires matching its properties to your primary goal.

- If your primary focus is high-temperature, non-stick performance: PTFE is an excellent choice for applications like non-stick coatings and seals, as long as you stay below the 260°C (500°F) continuous service limit.

- If your primary focus is broad chemical resistance: PTFE offers unparalleled protection against aggressive chemicals across a vast temperature range, making it ideal for linings, gaskets, and lab equipment.

- If your primary focus is mechanical strength under load: You should consider a reinforced grade of PTFE (e.g., glass- or carbon-filled) or an alternative high-performance polymer.

- If your application involves high-energy radiation: PTFE is a poor choice, and you should investigate other materials like PEEK or polyimides.

Ultimately, understanding both the high melting point and the practical service temperature of PTFE empowers you to use this remarkable material effectively and safely.

Summary Table:

| Property | Temperature | Key Insight |

|---|---|---|

| Melting Point | 327°C (621°F) | Crystalline structure breaks down into a gel. |

| Max Service Temp | 260°C (500°F) | Safe upper limit for continuous use; degradation accelerates above this. |

| Min Service Temp | -200°C (-328°F) | Remains flexible and functional at cryogenic temperatures. |

Need High-Performance PTFE Components That Withstand Extreme Temperatures?

KINTEK specializes in precision manufacturing of PTFE seals, liners, and custom labware for the semiconductor, medical, and industrial sectors. Our expertise ensures your components deliver reliable chemical resistance and thermal stability from cryogenic lows to 260°C.

We provide:

- Custom Fabrication: From prototypes to high-volume orders.

- Material Expertise: Optimal PTFE solutions for your specific thermal and chemical challenges.

- Precision Production: Components built to exact specifications for maximum performance and safety.

Contact KINTEK today to discuss your project requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are some applications of PTFE due to its properties? Discover Its Versatility in Demanding Industries

- What are the limitations of PTFE as a material? Key Mechanical Weaknesses to Consider

- Why is PTFE chemically resistant and what applications benefit from this? Discover the Ultimate Material for Harsh Environments

- What distinguishes Virgin PTFE from Reprocessed PTFE? Choose the Right Material for Your Application

- What is Teflon/PTFE material and what are its key properties? Unlock Its High-Performance Capabilities

- What are the characteristics of carbon-filled PTFE? A High-Performance Composite for Demanding Applications

- What are the notable physical and chemical properties of PTFE? Master Its Unique Strengths and Limitations

- What are the key properties of PTFE relevant to troubleshooting and maintenance? Master PTFE's Strengths and Weaknesses