At its core, Polytetrafluoroethylene (PTFE) is a high-performance synthetic fluoropolymer. Best known by the brand name Teflon, it is composed of a carbon chain fully encased by fluorine atoms. This unique molecular structure gives PTFE an exceptional combination of properties—including extreme chemical resistance, high-temperature stability, and an incredibly low-friction, non-stick surface—making it one of the most versatile and significant materials in modern engineering.

The true significance of PTFE lies not in a single characteristic, but in the rare combination of its properties. Its strong carbon-fluorine bonds create a material that is simultaneously chemically inert, thermally stable, and exceptionally slippery, a trifecta that solves critical challenges across countless industries.

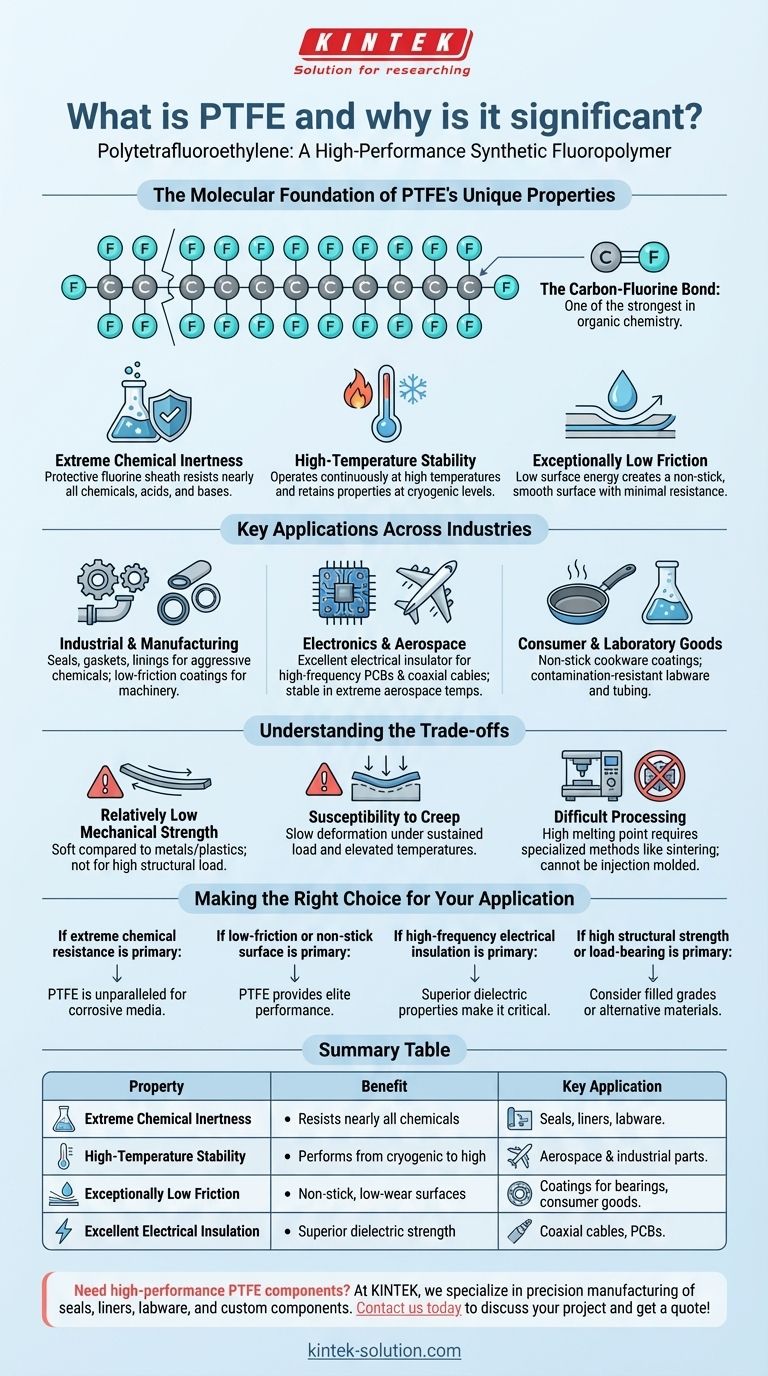

The Molecular Foundation of PTFE's Unique Properties

To understand PTFE's value, you must first understand its structure. Its remarkable capabilities are a direct result of its simple but powerful molecular makeup.

The Carbon-Fluorine Bond

PTFE consists of a long chain of carbon atoms, where each carbon is bonded to two fluorine atoms. The bond between carbon and fluorine is one of the strongest known in organic chemistry.

This powerful bond creates a tight, protective "sheath" of fluorine atoms around the carbon backbone, effectively shielding it from external chemical and thermal attacks.

Extreme Chemical Inertness

Because of this protective fluorine sheath, PTFE is one of the most non-reactive substances known. It is resistant to nearly all chemicals, acids, and bases.

Only highly reactive substances like molten alkali metals or hot fluorine gas can affect it, making PTFE an essential material for handling highly corrosive materials in laboratories and industrial plants.

High-Temperature Stability

The strength of the carbon-fluorine bonds also gives PTFE a very high melting point and excellent thermal stability. It can operate continuously at high temperatures without degrading.

Furthermore, it maintains its strength and flexibility even at cryogenic temperatures, a rare quality that makes it valuable for aerospace and specialized industrial applications.

Exceptionally Low Friction

The fluorine atoms on the surface of the PTFE molecule create a very low surface energy. This means other substances have a difficult time sticking to it, resulting in its famous non-stick quality.

This property also gives PTFE one of the lowest coefficients of friction of any solid material, making it an ideal coating for machine parts, bearings, and other applications where smooth, low-resistance movement is critical.

Key Applications Across Industries

PTFE's unique combination of properties has made it indispensable in a wide range of fields.

Industrial and Manufacturing

In industrial settings, PTFE is used for seals, gaskets, and linings for pipes and tanks that handle aggressive chemicals. Its low-friction properties are leveraged in coatings for bearings and machine parts to reduce wear and energy consumption.

Electronics and Aerospace

PTFE is an excellent electrical insulator with a high dielectric strength, making it a preferred material for high-frequency applications like coaxial cables and printed circuit boards (PCBs). Its stability across a wide temperature range is critical for aerospace components.

Consumer and Laboratory Goods

The most widely known application is the non-stick coating on cookware. In scientific settings, its extreme chemical resistance makes it the material of choice for laboratory equipment, containers, and tubing that must remain uncontaminated and resist corrosion.

Understanding the Trade-offs

No material is perfect, and making an informed decision requires understanding PTFE's limitations. Its unique strengths come with inherent compromises.

Relatively Low Mechanical Strength

While durable and tough, PTFE is a relatively soft material compared to engineering plastics or metals. It is not suitable for applications requiring high structural rigidity or load-bearing capacity on its own.

Susceptibility to Creep

Under a sustained load, especially at elevated temperatures, PTFE can slowly deform over time. This phenomenon, known as "creep" or "cold flow," must be accounted for in the design of parts like seals and gaskets.

Difficult Processing

PTFE's high melting point and high melt viscosity make it impossible to process using conventional techniques like injection molding. Instead, it requires specialized processes like compression molding and sintering, which can increase manufacturing complexity and cost.

Making the Right Choice for Your Application

Selecting PTFE depends entirely on whether its unique strengths align with your primary engineering goal.

- If your primary focus is extreme chemical resistance: PTFE is an unparalleled choice for handling corrosive media where nearly all other polymers and metals would fail.

- If your primary focus is creating a low-friction or non-stick surface: PTFE provides an elite level of performance for bearings, seals, and coatings that demand minimal resistance.

- If your primary focus is high-frequency electrical insulation: Its superior dielectric properties and thermal stability make it a critical material for demanding electronics and communication hardware.

- If your primary focus is high structural strength or load-bearing: You should consider filled grades of PTFE (e.g., glass or carbon-filled) or alternative materials, as pure PTFE will likely deform under significant mechanical stress.

Understanding PTFE's molecular structure is the key to unlocking its powerful capabilities for your specific engineering challenge.

Summary Table:

| Property | Benefit | Key Application |

|---|---|---|

| Extreme Chemical Inertness | Resists nearly all chemicals and acids | Seals, liners, and labware for corrosive environments |

| High-Temperature Stability | Performs from cryogenic to high temperatures | Aerospace components and high-temp industrial parts |

| Exceptionally Low Friction | Provides non-stick, low-wear surfaces | Coatings for bearings, seals, and consumer goods |

| Excellent Electrical Insulation | Superior dielectric strength for high-frequency use | Coaxial cables and printed circuit boards (PCBs) |

Need high-performance PTFE components tailored to your specific requirements?

At KINTEK, we specialize in the precision manufacturing of PTFE seals, liners, labware, and custom components. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise ensures your parts meet the highest standards for chemical resistance, thermal stability, and low friction.

We offer custom fabrication from prototypes to high-volume orders, helping you solve critical engineering challenges. Contact us today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What material is the PTFE bottle made from? Discover the Benefits of 100% Virgin PTFE

- What makes the PTFE bottle durable? Unmatched Chemical & Thermal Stability for Demanding Applications

- What are the unique properties of PTFE that make it commercially valuable? Unlock Unmatched Performance

- What are the common characteristics of Teflon? Unlocking Extreme Chemical and Thermal Resistance

- Why are PTFE vials considered environmentally friendly? Reduce Lab Waste with Durable Reusables