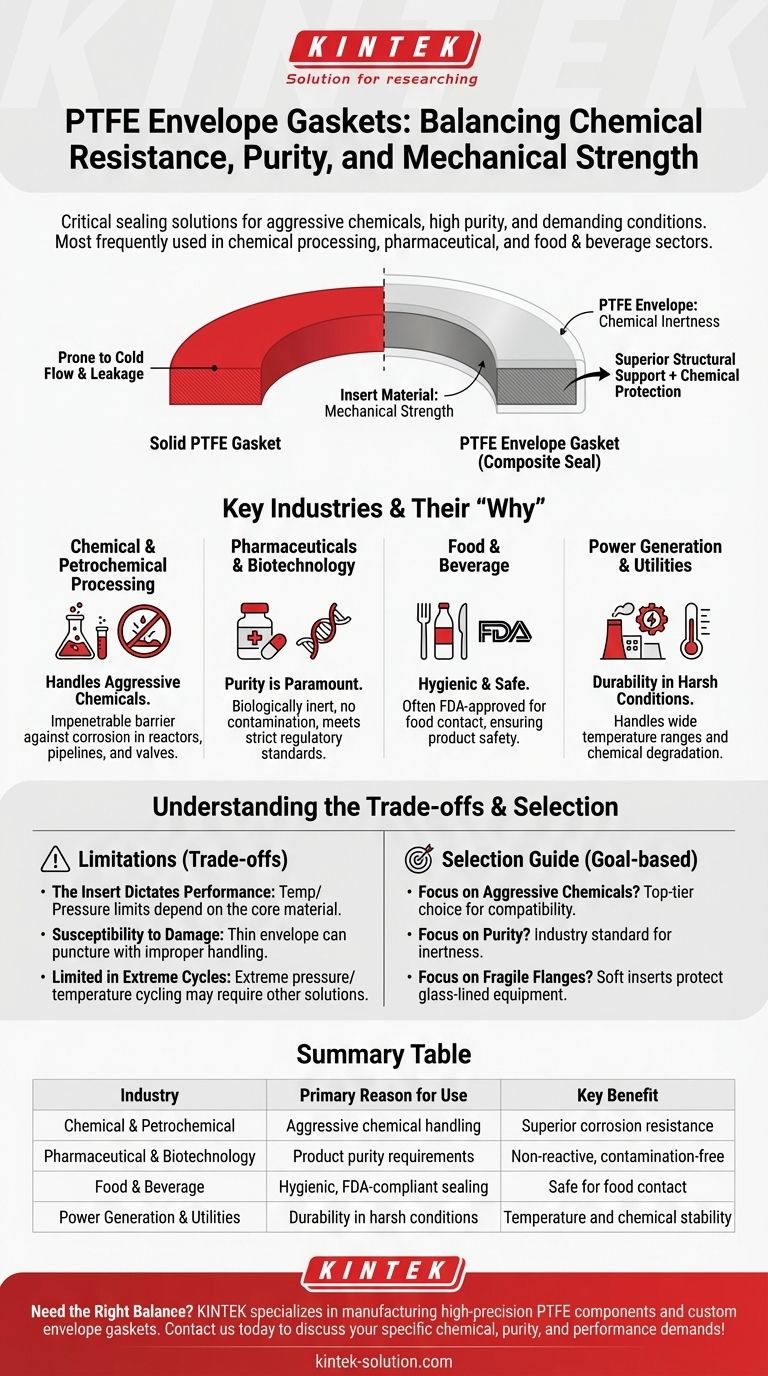

In short, PTFE envelope gaskets are critical sealing solutions in industries that handle aggressive chemicals, require high purity, or operate under demanding conditions. They are most frequently used in chemical processing, pharmaceutical manufacturing, and the food and beverage sectors due to their unique combination of chemical inertness and mechanical strength.

The central challenge is not just finding a chemically resistant seal, but finding one that is also mechanically stable and cost-effective. A PTFE envelope gasket solves this by combining a chemically inert PTFE shell with a structurally robust inner core, offering the best of both worlds for specific applications.

What Defines a PTFE Envelope Gasket?

A common point of confusion is the difference between a solid PTFE gasket and a PTFE envelope gasket. Understanding this distinction is key to knowing why it's chosen.

The Two-Material Solution

A PTFE envelope gasket is a composite seal. It consists of a softer, more robust insert material (like non-asbestos fiber or stainless steel) that is wrapped in a thin, protective PTFE envelope.

This design provides the exceptional chemical resistance of PTFE on all wetted surfaces while relying on the insert for mechanical strength, compressibility, and resistance to creep.

The Advantage Over Solid PTFE

Solid PTFE gaskets can be prone to cold flow, or creep, where the material deforms permanently under pressure, leading to a loss of bolt torque and potential leaks.

The internal core of an envelope gasket provides superior structural support, significantly reducing this issue and ensuring a more reliable, long-term seal under pressure.

Key Industries and Their "Why"

While many industries use these gaskets, a few rely on them for mission-critical processes. The reason is always tied back to the unique properties of that PTFE outer layer.

Chemical and Petrochemical Processing

This is the primary market. These industries handle highly corrosive media, including strong acids, solvents, and bases that would degrade most other sealing materials.

The PTFE envelope creates an impenetrable barrier, protecting the gasket's core and the integrity of the flange joint from chemical attack. They are used extensively in pipelines, reactors, and valve connections.

Pharmaceuticals and Biotechnology

Purity is the dominant concern here. PTFE is biologically inert and does not contaminate the process media, which is essential for maintaining product safety and efficacy.

These gaskets ensure that no unwanted materials leach into sensitive drug formulations or bioprocesses, meeting strict regulatory standards for cleanliness and non-reactivity.

Food and Beverage

Similar to pharmaceuticals, this industry requires materials that are safe for food contact. PTFE is often FDA-approved, making it a default choice for hygienic applications.

Envelope gaskets are used to seal pipes, tanks, and processing equipment, preventing contamination and ensuring the final product remains pure and safe for consumption.

Power Generation and Utilities

In power plants and water treatment facilities, seals must be stable and durable. These gaskets are used in applications involving harsh chemicals for water treatment or in auxiliary systems that require reliable, long-term sealing.

Their ability to handle a wide range of temperatures and resist chemical degradation makes them a dependable choice for ensuring operational stability.

Understanding the Trade-offs

No solution is perfect. Being an effective advisor means acknowledging limitations.

The Insert Dictates Performance

While the PTFE provides chemical protection, the gasket's overall temperature and pressure limits are determined by the insert material. A standard fiber insert will have a much lower rating than a stainless steel one.

You must specify the insert based on the system's mechanical and thermal demands, not just the chemical environment.

Susceptibility to Damage

The PTFE envelope is relatively thin. Careless handling or improper installation techniques, such as over-tightening or using damaged flange surfaces, can puncture or tear the envelope.

A compromised envelope exposes the non-resistant core material, leading to rapid gasket failure. Meticulous installation is not optional; it is a requirement.

Limited Use in Extreme Pressure/Temperature Cycles

While excellent in many scenarios, systems with extreme pressure and temperature cycling may demand a more robust solution like a spiral wound gasket. The differential expansion between the insert and the PTFE envelope can become a factor in the most demanding cyclic operations.

Making the Right Choice for Your Goal

To select the correct gasket, you must prioritize your single most important requirement.

- If your primary focus is aggressive chemical resistance: A PTFE envelope gasket is a top-tier choice, offering near-universal chemical compatibility at a lower cost than exotic metal seals.

- If your primary focus is product purity and hygiene: This gasket is an industry standard in pharmaceutical and food applications for its inertness and FDA compliance.

- If your primary focus is sealing fragile flanges (e.g., glass-lined or ceramic): The soft, compressible nature of many envelope gasket inserts allows for an effective seal with lower bolt load, protecting the flanges from cracking.

- If your primary focus is high pressure and temperature combined: Carefully evaluate the insert material's capabilities, or consider alternative gasket types like spiral wound gaskets specifically designed for those extremes.

By understanding its composite design, you can confidently determine if a PTFE envelope gasket provides the precise balance of chemical protection and mechanical performance your system demands.

Summary Table:

| Industry | Primary Reason for Use | Key Benefit |

|---|---|---|

| Chemical & Petrochemical | Aggressive chemical handling | Superior corrosion resistance |

| Pharmaceutical & Biotechnology | Product purity requirements | Non-reactive, contamination-free |

| Food & Beverage | Hygienic, FDA-compliant sealing | Safe for food contact |

| Power Generation & Utilities | Durability in harsh conditions | Temperature and chemical stability |

Need a PTFE envelope gasket that balances chemical resistance with mechanical strength?

KINTEK specializes in manufacturing high-precision PTFE components—including custom envelope gaskets—for semiconductor, medical, laboratory, and industrial applications. Whether you require prototypes or high-volume orders, our expertise ensures a seal that meets your exact chemical, purity, and performance demands.

Contact us today to discuss your specific requirements and get a solution tailored to your industry’s challenges!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What advantages do PTFE coatings offer in terms of durability and maintenance? Maximize Component Lifespan

- What are some polymers similar to PTFE? Discover Melt-Processible Fluoropolymer Alternatives

- What are the structural differences between PTFE lined and hard seal butterfly valves? A Guide to Sealing Mechanisms

- How does PTFE prevent corrosion in piping systems? A Complete Guide to Chemical & Galvanic Protection

- What are Teflon encapsulated O-Rings and what materials are they crafted with? Superior Seals for Harsh Environments

- What are the advantages of PTFE as a sealing material? Superior Performance in Extreme Conditions

- How are PTFE tubes manufactured and what are their uses? A Guide to High-Performance Tubing Solutions

- What electrical properties do PTFE gaskets possess? Unmatched Insulation for High-Frequency & High-Voltage Applications