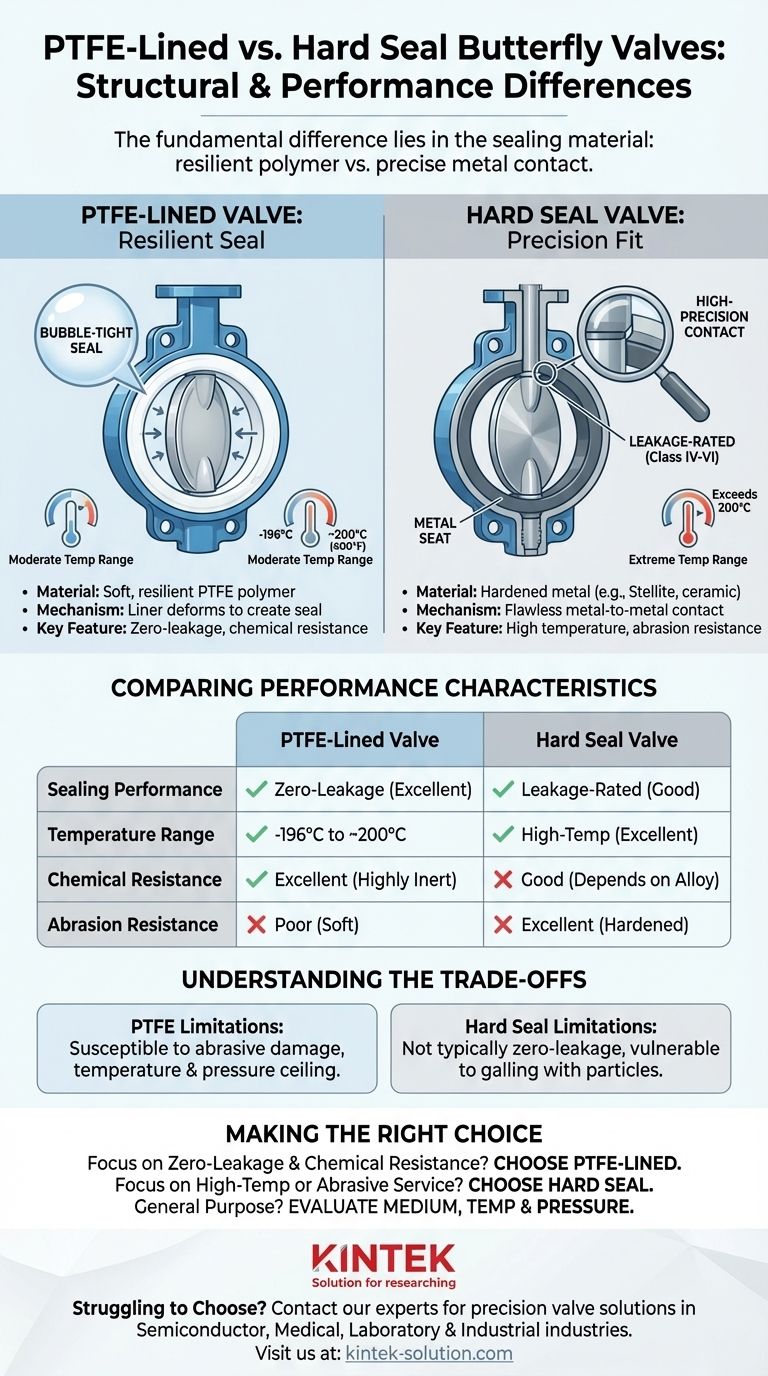

The fundamental structural difference between PTFE-lined and hard seal butterfly valves lies entirely in the materials used at the point of sealing. A PTFE-lined valve uses a soft, resilient polymer (polytetrafluoroethylene) on its sealing surfaces to create the seal. In contrast, a hard seal valve relies on the precise contact between two metal or other hard material surfaces, such as Stellite or ceramic.

The choice between these two valve types is a direct trade-off. PTFE-lined valves offer superior, zero-leakage sealing and chemical resistance, while hard seal valves provide unmatched durability in high-temperature and high-abrasion environments.

Deconstructing the Sealing Mechanism

To understand the performance differences, you must first understand how each valve type achieves a seal. The structural design dictates the valve's core capabilities.

PTFE-Lined Valves: The Resilient Seal

A PTFE-lined valve functions much like a gasket. The disc of the valve closes against a soft, thick liner made of PTFE.

This resilient material deforms slightly under pressure, filling any microscopic imperfections to create an exceptionally tight, or bubble-tight, seal.

Because PTFE is one of the most chemically inert substances available, this design is ideal for isolating and controlling highly corrosive media. The liner also protects the valve's metal body from chemical attack.

Hard Seal Valves: The Precision Fit

A hard seal valve achieves its seal through high-precision engineering. The edge of the metal disc and the valve's metal seat are machined to fit together with extremely tight tolerances.

Unlike a soft seal, there is no resilient material to deform. The quality of the seal depends entirely on the flawless, forceful contact between these two hardened surfaces.

This metal-to-metal design is inherently robust and can withstand conditions that would destroy a soft polymer liner.

Comparing Key Performance Characteristics

The structural differences in sealing mechanisms lead to distinct advantages and disadvantages in real-world applications.

Sealing Performance

PTFE-lined valves are the clear winner for applications requiring a zero-leakage seal. Their ability to create a bubble-tight shutoff makes them essential for handling hazardous chemicals or in processes where no leakage is permissible.

Hard seal valves, by design, are not typically zero-leakage. They are rated according to leakage classes (e.g., ANSI/FCI 70-2 Class IV, V, or VI), which permit a very small, defined amount of leakage. While excellent, it is not a "perfect" seal.

Temperature and Pressure Range

Hard seal valves excel in extreme temperature environments. Their all-metal construction allows them to operate reliably in high-heat processes well above the limits of any polymer.

PTFE-lined valves have a broad but finite operating temperature range, typically from cryogenic levels (-196°C) up to approximately 200°C (400°F). Exceeding this upper limit will cause the PTFE to degrade and fail.

Chemical and Abrasion Resistance

PTFE-lined valves offer unparalleled corrosion resistance. They are the standard choice for aggressive media like strong acids, bases, and other corrosive chemicals.

Hard seal valves are the superior choice for abrasion resistance. In services with abrasive particles, such as slurries or high-particulate gas, a soft PTFE liner would be quickly eroded and destroyed. The hardened metal surfaces of a hard seal valve are built to withstand this physical wear.

Understanding the Trade-offs

Choosing the right valve requires acknowledging the inherent limitations of each design. There is no single "best" valve, only the best valve for a specific task.

The Cost of a Perfect Seal: PTFE Limitations

The primary weakness of a PTFE liner is its lack of physical robustness. It is susceptible to damage from abrasive particles and cannot be used in high-wear applications. Furthermore, its performance is strictly limited by its temperature and pressure ceiling.

The Price of Durability: Hard Seal Limitations

The main compromise with a hard seal valve is its sealing capability. Achieving a near-perfect seal requires more expensive, high-precision manufacturing, and even then, it may not achieve the bubble-tight shutoff of a soft seal. These valves are also vulnerable to galling or scoring if particulate gets trapped between the metal sealing surfaces.

Making the Right Choice for Your Application

Your selection should be driven entirely by your process conditions and performance requirements.

- If your primary focus is zero-leakage sealing and chemical resistance: Choose a PTFE-lined valve for its bubble-tight shutoff and inertness, especially when handling corrosive media within its temperature limits.

- If your primary focus is high-temperature or abrasive service: Opt for a hard seal valve for its unmatched durability in processes exceeding 200°C or containing abrasive particles that would destroy a soft seal.

- If your primary focus is general-purpose flow control: Carefully evaluate your medium, temperature, and pressure. For many standard applications, a PTFE-lined valve offers an excellent balance of sealing performance and cost-effectiveness.

Understanding this core structural trade-off empowers you to select the right valve based on engineering requirements, not just material labels.

Summary Table:

| Feature | PTFE-Lined Valve | Hard Seal Valve |

|---|---|---|

| Sealing Mechanism | Resilient PTFE liner deforms for a bubble-tight seal. | Precision metal-to-metal contact. |

| Sealing Performance | Zero-leakage (bubble-tight). | Leakage-rated (e.g., ANSI Class IV-VI). |

| Temperature Range | -196°C to ~200°C (400°F). | High-temperature (exceeds 200°C). |

| Chemical Resistance | Excellent (highly inert). | Good (depends on metal alloy). |

| Abrasion Resistance | Poor (PTFE is soft). | Excellent (hardened surfaces). |

Struggling to Choose the Right Valve for Your Process?

At KINTEK, we understand that the right seal is critical to your system's performance, safety, and longevity. Whether your application demands the zero-leakage sealing and chemical inertness of a PTFE component or the high-temperature durability of a hard seal, our expertise is your solution.

We specialize in the precision manufacturing and custom fabrication of high-performance PTFE components—including seals, liners, and custom labware—for the most demanding industries:

- Semiconductor

- Medical & Pharmaceutical

- Laboratory & Analytical

- Industrial Processing

Let us help you optimize your fluid handling systems. We provide everything from initial prototypes to high-volume production, ensuring you get a valve solution perfectly engineered for your specific media, temperature, and pressure requirements.

Contact our experts today for a consultation and let's discuss how we can bring reliability and precision to your application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the different types of Teflon gland packing available? Select the Right PTFE Seal for Your Application

- What is the conclusion regarding gasket selection for ISO tank applications? PTFE Envelope Gaskets for Safe Transport

- What challenges should be identified for an O-ring application? A Guide to Ensuring Seal Success

- What are the standard sizes available for PTFE wear strips and bands? Custom Sizes for Optimal Performance

- What role does PTFE's temperature resistance play in medical applications? Ensuring Sterilization & Implant Safety

- What customization options are available for Teflon rotary shaft seals? Tailor for Performance & Reliability

- How do PTFE O-rings perform against chemicals? Achieve Unmatched Chemical Resistance

- What material can enhance the benefits of ring-type gaskets? Boost Performance with PTFE in Harsh Environments