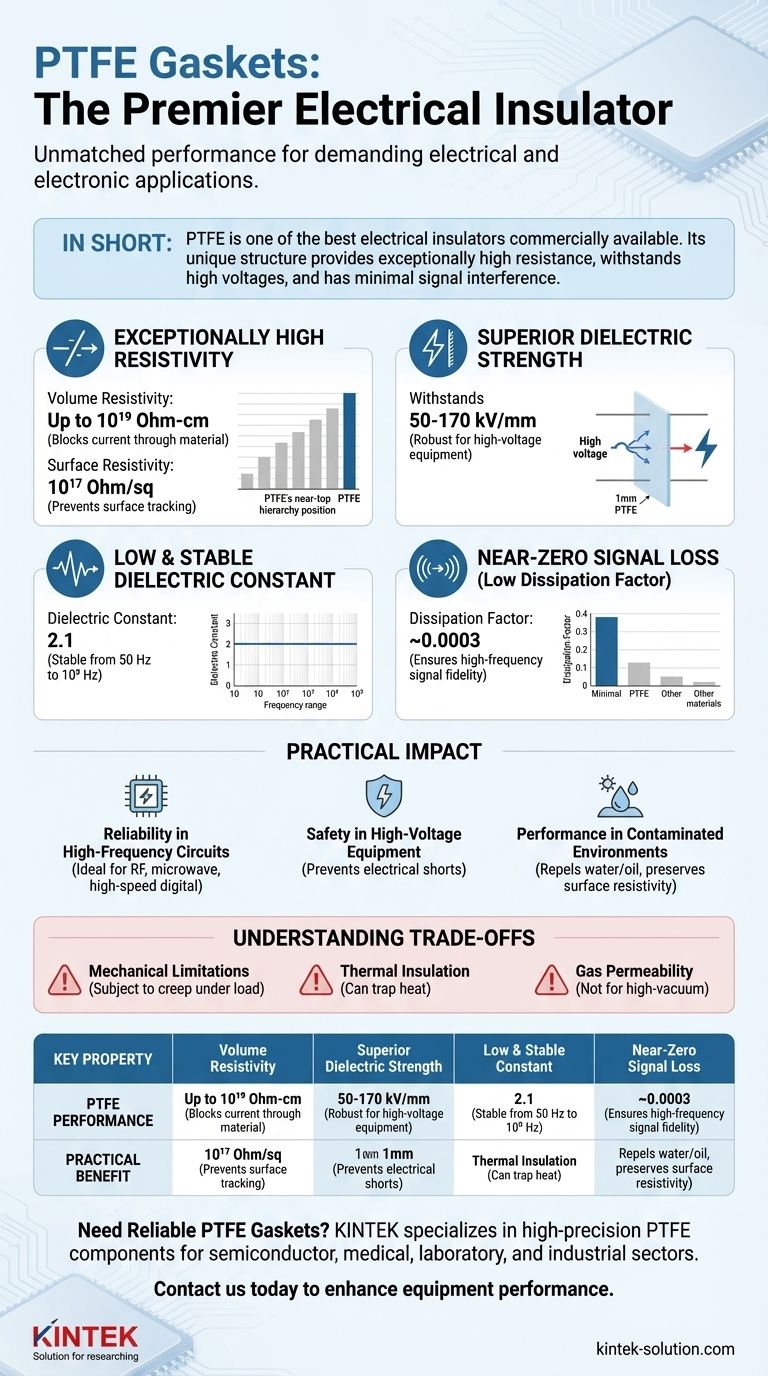

In short, PTFE is one of the best electrical insulators commercially available. Its unique molecular structure gives it a powerful combination of properties, including exceptionally high resistance to electrical current, the ability to withstand very high voltages without breaking down, and minimal interference with high-frequency signals. This makes PTFE gaskets a default choice for demanding electrical and electronic applications.

While many materials are good insulators, PTFE stands apart due to its elite performance across multiple electrical metrics simultaneously. Its value lies not just in its ability to block current, but in its stability at high frequencies and in harsh environmental conditions, making it a uniquely reliable material for sensitive applications.

Why PTFE Is an Elite Electrical Insulator

The exceptional insulating capability of PTFE stems from several distinct and measurable properties. Each contributes to its reliability in different ways.

Exceptionally High Resistivity

Resistivity measures a material's fundamental opposition to the flow of electrical current. PTFE excels in both volume resistivity (current flowing through the material) and surface resistivity (current flowing across its surface).

With a volume resistivity as high as 10¹⁹ Ohm-cm, PTFE is near the top of the insulation hierarchy. This astronomical resistance effectively stops current from passing through the gasket.

Its high surface resistivity of 10¹⁷ Ohm/sq ensures that electricity does not easily find a path along the gasket's exterior, preventing surface tracking currents.

Superior Dielectric Strength

Dielectric strength is the maximum electric field a material can withstand before it breaks down and begins to conduct electricity.

PTFE has a very high dielectric strength, typically in the range of 50 to 170 kV/mm. This means a 1mm thick sheet of PTFE can theoretically withstand up to 170,000 volts, making it a robust choice for high-voltage equipment.

Low and Stable Dielectric Constant

The dielectric constant indicates how a material can store electrical energy in an electric field. For high-frequency applications (like in circuit boards or antennas), a low number is critical.

PTFE has a very low dielectric constant of 2.1, and crucially, this value remains stable across a vast frequency range (from 50 Hz to 10⁹ Hz). This consistency prevents signal distortion and energy loss in sensitive electronics.

Near-Zero Signal Loss (Low Dissipation Factor)

The dissipation factor, or loss tangent, measures how much signal energy is lost as heat when it passes through the material. A low number signifies a highly efficient insulator.

PTFE's extremely low dissipation factor of ~0.0003 ensures that high-frequency signals pass through with almost perfect fidelity, minimizing heat buildup and signal degradation.

The Practical Impact of PTFE's Properties

These technical specifications translate directly into real-world performance advantages for engineering applications.

Reliability in High-Frequency Circuits

The combination of a low dielectric constant and a low dissipation factor makes PTFE an ideal material for RF, microwave, and high-speed digital circuits. It ensures signal integrity is maintained.

Safety in High-Voltage Equipment

The high dielectric strength and volume resistivity provide a powerful barrier against electrical shorts. This is critical for ensuring the safety and longevity of power electronics, transformers, and other high-voltage components.

Performance in Contaminated Environments

PTFE has extremely low surface tension, which makes it repel both water (hydrophobic) and oils (oleophobic).

This property is a significant advantage, as it prevents a conductive film of moisture or grease from forming on the gasket's surface. This preserves its high surface resistivity even in dirty or humid conditions.

Understanding the Trade-offs

No material is perfect for every situation. While its electrical properties are superb, its mechanical and thermal characteristics present important trade-offs.

Mechanical Limitations

PTFE is a relatively soft material. Under sustained compressive load, it is subject to creep, or "cold flow," where the material slowly deforms. This must be accounted for in gasket designs that require long-term, high-pressure sealing.

Thermal Insulation

The references note that PTFE is an excellent thermal insulator. While often a benefit, this can be a drawback in applications where components generate heat. The PTFE gasket can trap this heat, potentially raising the operating temperature of the assembly.

Gas Permeability

PTFE has a relatively high gas permeability, similar to silicone. This makes it unsuitable for high-vacuum applications or situations where preventing gas leakage is the primary requirement.

Making the Right Choice for Your Application

Selecting PTFE should be a deliberate decision based on your primary engineering goal.

- If your primary focus is high-frequency signal integrity: PTFE is a top-tier choice due to its low and stable dielectric constant and minimal dissipation factor.

- If your primary focus is high-voltage insulation: PTFE's massive dielectric strength and volume resistivity provide an exceptional factor of safety.

- If your application involves potential surface contamination: PTFE's natural resistance to water and oil helps guarantee its surface insulation performance over time.

- If your design involves high mechanical loads or vacuum sealing: You must account for PTFE's tendency to creep and its gas permeability, potentially considering a filled-PTFE or an alternative material.

By understanding these distinct electrical and mechanical characteristics, you can confidently leverage PTFE where its unique strengths provide maximum value and reliability.

Summary Table:

| Key Electrical Property | PTFE Performance | Practical Benefit |

|---|---|---|

| Volume Resistivity | Up to 10¹⁹ Ohm-cm | Blocks current flow through the gasket |

| Dielectric Strength | 50-170 kV/mm | Withstands extremely high voltages |

| Dielectric Constant | 2.1 (stable across frequencies) | Maintains signal integrity in high-frequency circuits |

| Dissipation Factor | ~0.0003 | Minimizes signal loss and heat generation |

Need reliable PTFE gaskets for your critical electrical applications?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals, liners, and custom labware, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get components that deliver the superior electrical insulation and signal integrity your projects demand.

Contact us today to discuss how our PTFE solutions can enhance the performance and reliability of your equipment. Get in touch →

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the primary uses of Teflon encapsulated O-Rings? Seal Against Aggressive Chemicals & High Temperatures

- What are the material properties of PTFE relevant to CNC machining? Mastering Softness & Heat for Precision

- What makes PTFE-lined diaphragm valves suitable for wastewater treatment? Ensure Reliability and Cost Savings

- What are some common fillers used to improve PTFE properties for valve seats? Boost Performance & Durability

- What industrial applications commonly use PTFE packing? Essential Sealing Solutions for Demanding Industries

- Why are PTFE-free bushings considered environmentally friendly? Reduce PFAS Risk & Enhance Sustainability

- How to choose the right PTFE lined butterfly valve? A Guide for Maximum Chemical Resistance & Reliability

- What guidelines should be followed for the installation and maintenance of Teflon parts? Ensure Longevity & Performance