Polytetrafluoroethylene (PTFE) is a premier sealing material primarily because of its extraordinary chemical inertness, an exceptionally wide operating temperature range, and one of the lowest coefficients of friction of any solid. This unique combination of properties makes it a default choice for the most demanding industrial, medical, and food-grade applications.

The core advantage of PTFE isn't just one elite property, but its rare ability to deliver several at once. It solves sealing challenges in extreme environments where most other materials would fail from chemical attack, temperature degradation, or excessive friction.

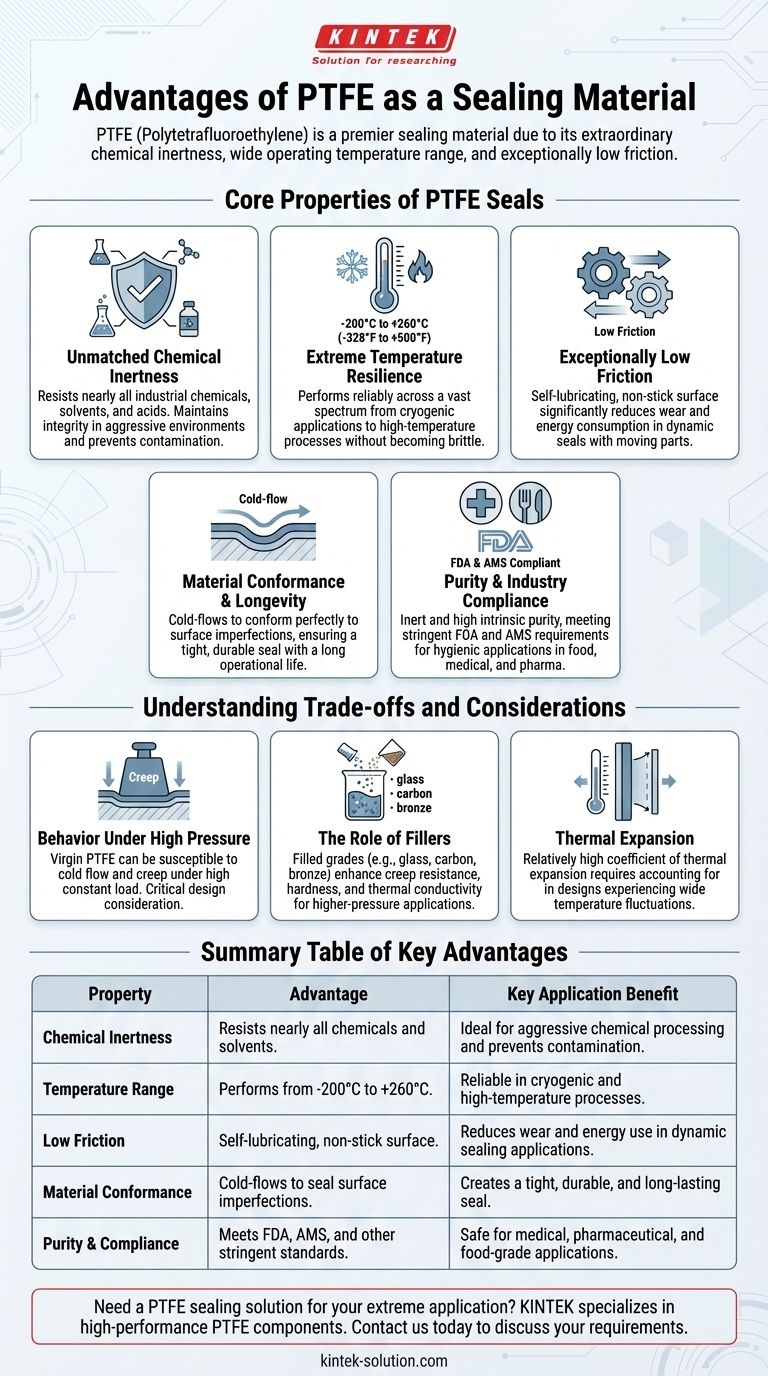

The Core Properties of PTFE Seals

To understand why PTFE is so effective, we must examine its fundamental characteristics. Each property addresses a specific set of engineering challenges that other materials struggle to overcome.

Unmatched Chemical Inertness

PTFE is renowned for its resistance to nearly all industrial chemicals, solvents, acids, and corrosive agents. It is highly insoluble and maintains its integrity even in the most aggressive environments.

This chemical stability prevents the seal from degrading and, just as importantly, prevents it from contaminating sensitive mediums. The only known exceptions are molten alkali metals and certain highly reactive fluorine compounds under extreme conditions.

Extreme Temperature Resilience

PTFE performs reliably across a vast temperature spectrum, typically from -200°C to +260°C (-328°F to +500°F).

This allows it to be used in everything from cryogenic applications to high-temperature industrial processes without becoming brittle or losing its sealing capability, a range that few other polymers can match.

Exceptionally Low Friction

With an extremely low coefficient of friction, PTFE is a self-lubricating, non-stick material. For dynamic seals involving moving parts, this means significantly reduced wear and tear on the components.

This high gliding ability lowers the energy required for movement and prevents the "stick-slip" phenomenon, ensuring smooth and consistent operation over the seal's long life.

Material Conformance and Longevity

A critical, and often misunderstood, property of PTFE is its lack of "memory," which results in material creep. While often a negative trait, in sealing this allows the PTFE to cold-flow and conform perfectly to the microscopic imperfections of a mating surface.

This ensures an exceptionally tight and durable seal. This high resilience, combined with its resistance to degradation, gives PTFE seals a very long operational life.

Purity and Industry Compliance

Because of its inertness and high intrinsic purity, PTFE meets stringent FDA and AMS requirements. This makes it a go-to material for hygienic applications in the food, beverage, medical, and pharmaceutical industries where preventing contamination is paramount.

Understanding the Trade-offs

No material is perfect for every scenario. An objective assessment requires acknowledging PTFE's limitations to ensure it is applied correctly.

Behavior Under High Pressure

Pure, or "virgin," PTFE can be susceptible to cold flow and creep under high mechanical pressure. Over time, a constant high load can cause the material to deform, potentially compromising the seal.

This is a critical design consideration in high-pressure static sealing applications.

The Role of Fillers

To counteract its limitations, PTFE is often blended with fillers like glass, carbon, or bronze. These filled grades of PTFE significantly enhance properties like creep resistance, hardness, and thermal conductivity, making them suitable for higher-pressure and higher-load scenarios.

Thermal Expansion

PTFE has a relatively high coefficient of thermal expansion compared to metals. In assemblies that experience wide temperature fluctuations, this expansion and contraction must be accounted for in the design to maintain seal integrity.

Making the Right Choice for Your Application

Selecting the right material depends entirely on the operational demands of your system. PTFE should be considered when performance under extreme conditions is non-negotiable.

- If your primary focus is aggressive chemical environments: PTFE's chemical inertness is virtually unparalleled, protecting both the seal and the medium from contamination.

- If your primary focus is a wide operating temperature range: PTFE maintains its integrity from cryogenic lows to high industrial heat, offering reliability where other polymers would fail.

- If your primary focus is dynamic sealing with low friction: PTFE's self-lubricating properties reduce wear and energy consumption in applications with moving parts.

- If your primary focus is high-pressure or high-load applications: You should strongly consider a filled grade of PTFE to mitigate the material's natural tendency to deform under stress.

By understanding these distinct properties and trade-offs, you can leverage PTFE's unique strengths to solve the most demanding sealing challenges.

Summary Table:

| Property | Advantage | Key Application Benefit |

|---|---|---|

| Chemical Inertness | Resists nearly all chemicals and solvents. | Ideal for aggressive chemical processing and prevents contamination. |

| Temperature Range | Performs from -200°C to +260°C. | Reliable in cryogenic and high-temperature processes. |

| Low Friction | Self-lubricating, non-stick surface. | Reduces wear and energy use in dynamic sealing applications. |

| Material Conformance | Cold-flows to seal surface imperfections. | Creates a tight, durable, and long-lasting seal. |

| Purity & Compliance | Meets FDA, AMS, and other stringent standards. | Safe for medical, pharmaceutical, and food-grade applications. |

Need a PTFE sealing solution for your extreme application?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including seals, liners, and custom labware. We serve the semiconductor, medical, laboratory, and industrial sectors, providing custom fabrication from prototypes to high-volume orders. Our expertise ensures you get a seal that delivers superior chemical resistance, temperature resilience, and longevity.

Contact KINTEK today to discuss your specific requirements and leverage our material science expertise for your most demanding sealing challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- How is PTFE used in industrial processes? Maximize Safety and Efficiency