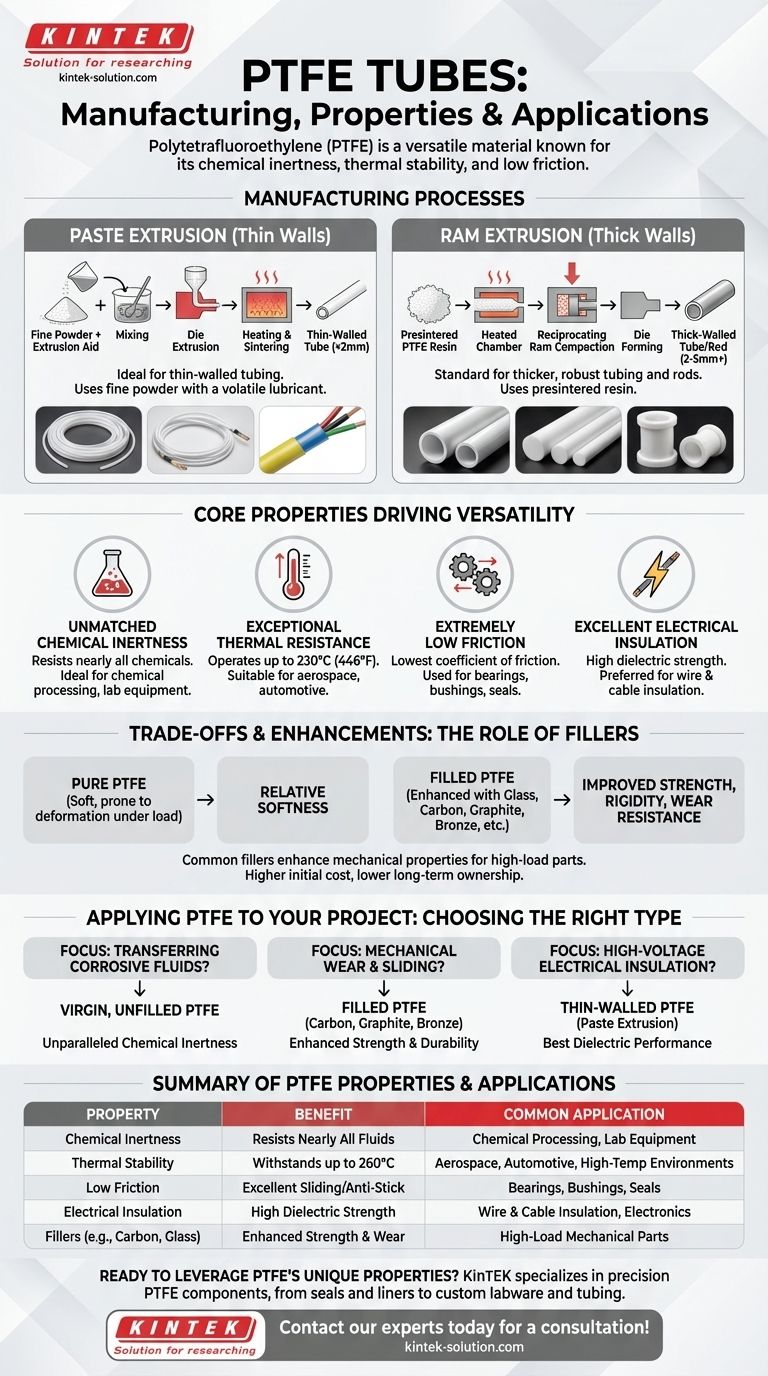

At its core, Polytetrafluoroethylene (PTFE) tubing is manufactured through two primary methods: paste extrusion and ram extrusion. Paste extrusion, which uses fine powders mixed with an extrusion aid, is ideal for creating thin-walled tubes, while ram extrusion uses a presintered resin to form thicker tubes and other robust shapes for industrial use.

PTFE is not just a single material but a versatile platform. Its manufacturing process is chosen based on the desired physical dimensions, while its true value comes from its unique combination of chemical inertness, thermal stability, and low friction, making it a go-to solution for the most demanding engineering challenges.

The Manufacturing Process: From Powder to Tube

The method used to create a PTFE tube is dictated by the final application's requirements, primarily wall thickness and overall dimensions.

Paste Extrusion for Thinner Walls

Paste extrusion is the process of choice for producing thin-walled tubing, typically with a wall thickness under 2mm.

This technique involves blending a fine PTFE powder with a volatile lubricant or "extrusion aid." This mixture is then forced through a die to form the tube shape, after which it is heated to evaporate the aid and sinter the PTFE particles into a solid, coherent tube.

Ram Extrusion for Thicker Walls

For thicker and more robust tubing (2-5mm wall thickness) or solid rods, ram extrusion is the standard method.

This process uses a presintered PTFE resin that is fed into a heated chamber. A reciprocating ram then compacts and forces the material through a die, incrementally forming the final shape.

Core Properties Driving PTFE's Versatility

PTFE's widespread adoption in critical industries is not accidental. It stems from a unique set of intrinsic properties that allow it to perform where other materials fail.

Unmatched Chemical Inertness

PTFE is non-reactive to nearly all industrial chemicals and corrosive fluids. This makes it an essential material for lining pipes, valves, and tanks in chemical processing plants, ensuring the safe transfer of aggressive substances.

Exceptional Thermal Resistance

This material can operate reliably across a vast temperature range, withstanding temperatures up to 230°C (446°F). This stability makes it suitable for high-temperature applications in aerospace, automotive, and industrial manufacturing.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, a property famously used in non-stick cookware. In industrial settings, this quality is leveraged for components requiring smooth, sliding action, such as bearings, bushings, and gears.

Excellent Electrical Insulation

PTFE is a superb electrical insulator with high dielectric strength. This makes thin-walled PTFE tubing a preferred choice for insulating wires and cables in electronics and electrical systems.

Understanding the Trade-offs and Enhancements

While pure PTFE is remarkable, it isn't the perfect solution for every problem. Its properties can be precisely tailored to meet specific mechanical demands.

The Role of Fillers

To enhance specific characteristics, various fillers can be blended with the base PTFE resin before extrusion. Common fillers include glass fiber, carbon, graphite, bronze, and molybdenum disulfide.

Enhancing Mechanical Properties

Pure PTFE can be relatively soft and prone to deformation under load. Adding fillers like carbon or glass fiber significantly improves its compressive strength, rigidity, and wear resistance, making it suitable for high-load mechanical parts.

A Cost-Effective Long-Term Solution

While the initial cost of PTFE components can be higher than conventional materials, their incredible durability and resistance to chemical attack and wear result in a lower total cost of ownership. They reduce downtime, maintenance, and replacement frequency in harsh environments.

How to Apply This to Your Project

Choosing the right type of PTFE tubing depends entirely on the demands of your specific application.

- If your primary focus is transferring corrosive fluids: Virgin, unfilled PTFE tubing is the ideal choice due to its unparalleled chemical inertness.

- If your primary focus is mechanical wear and sliding action: A filled PTFE with additives like carbon, graphite, or bronze will provide the necessary strength and durability.

- If your primary focus is high-voltage electrical insulation: Thin-walled PTFE tubing manufactured via paste extrusion offers the best dielectric performance.

Ultimately, understanding these core properties allows you to leverage PTFE as a powerful problem-solving material in modern engineering.

Summary Table:

| Property | Benefit | Common Application |

|---|---|---|

| Chemical Inertness | Resists nearly all corrosive fluids | Chemical processing, lab equipment |

| Thermal Stability | Withstands temperatures up to 260°C | Aerospace, automotive, high-temp environments |

| Low Friction | Excellent for sliding/anti-stick uses | Bearings, bushings, seals |

| Electrical Insulation | High dielectric strength | Wire & cable insulation, electronics |

| Fillers (e.g., Carbon, Glass) | Enhanced strength & wear resistance | High-load mechanical parts |

Ready to leverage PTFE's unique properties for your project?

At KINTEK, we specialize in manufacturing precision PTFE components—from seals and liners to custom labware and tubing. Whether you need the chemical resistance of virgin PTFE for corrosive fluid transfer or the enhanced durability of filled PTFE for mechanical parts, our custom fabrication services cover everything from prototypes to high-volume orders.

Let us help you solve your most demanding engineering challenges. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs