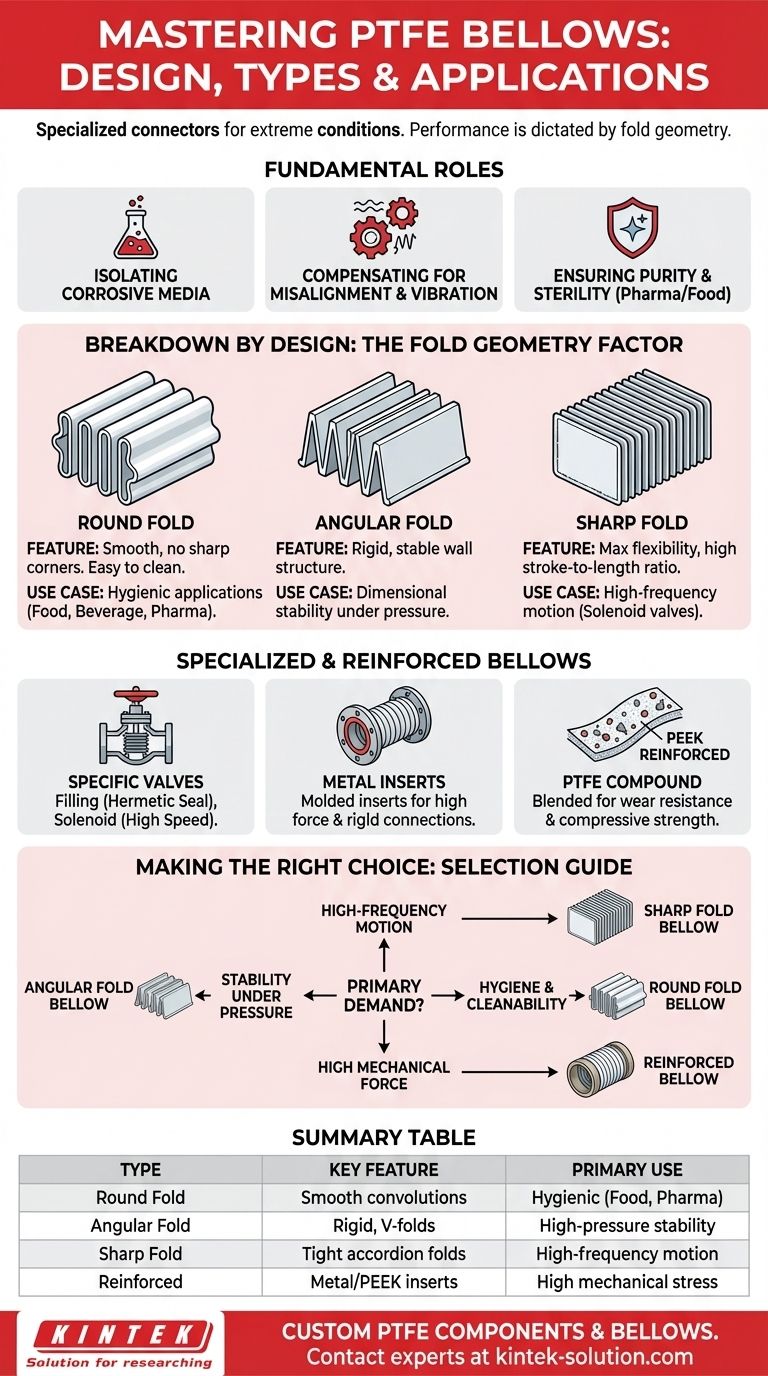

At their core, PTFE bellows are specialized flexible connectors engineered for extreme conditions where other materials fail. The primary types are distinguished by their fold geometry—such as round, angular, or sharp folds—and whether they are reinforced with materials like metal or PEEK to handle higher mechanical stress. Each design directly addresses a specific operational need, from high-frequency movement to stability under pressure.

The most critical factor in selecting a PTFE bellow is not the material itself, but the design of its structure. The shape of the folds and the presence of reinforcements determine its suitability for a given application, dictating its flexibility, pressure rating, and overall durability.

The Fundamental Role of PTFE Bellows

Before choosing a type, it's essential to understand the problems PTFE bellows are designed to solve. They act as a critical interface in demanding systems, protecting equipment from various stressors.

### Isolating Corrosive Media

The primary advantage of PTFE (polytetrafluoroethylene) is its near-universal chemical inertness. Bellows made from PTFE are used to create a flexible, leak-proof barrier in pumps, valves, and reactors, preventing aggressive chemicals from damaging sensitive mechanical components.

### Compensating for Misalignment and Vibration

No system is perfectly static. PTFE bellows absorb thermal expansion, mechanical vibration, and minor pipe or component misalignment. This flexibility prevents stress fractures in rigid piping and extends the life of connected equipment.

### Ensuring Purity and Sterility

In industries like pharmaceuticals, food and beverage, and semiconductors, preventing contamination is paramount. The non-stick, smooth surface of certain PTFE bellows designs makes them easy to clean and sterilizes, ensuring the integrity of the process medium.

A Breakdown of Bellows by Design

The physical geometry of a bellow's convolutions (folds) is the most significant factor in its performance. Each shape offers a distinct balance between flexibility and rigidity.

### Round Fold Bellows

This design features smooth, rounded convolutions. Its primary advantage is the lack of sharp corners where material or bacteria could accumulate, making it exceptionally easy to clean.

It is the standard choice for hygienic applications in the food, beverage, and pharmaceutical industries. While offering good flexibility, it is best suited for medium-pressure environments.

### Angular Fold Bellows

Angular fold bellows have a distinct "V" shape, which creates a more rigid and stable wall structure compared to round folds. This rigidity allows them to withstand higher internal or external pressures without collapsing.

They are ideal for applications requiring dimensional stability under pressure but where extreme flexibility is a secondary concern.

### Sharp Fold Bellows

Characterized by tight, accordion-like folds, this design maximizes flexibility and allows for a high stroke-to-length ratio. It can compress and extend significantly with minimal force.

This makes it the perfect choice for dynamic, high-frequency applications such as in solenoid valves or dosing pumps, which operate in low-pressure environments but require rapid and repeated movement.

Specialized and Reinforced Bellows

When standard PTFE designs cannot meet the mechanical demands of an application, reinforced or specialized bellows are used.

### Bellows for Specific Valve Types

Bellows are often tailored for specific components. Bellows for filling valves are engineered for a perfect hermetic seal to separate the product from the valve's mechanical actuators.

Those for solenoid valves are a type of sharp fold bellow, optimized for the high speed and millions of cycles required for valve actuation.

### Bellows with Metal Inserts

For applications involving higher forces or the need for a rigid connection point, metal inserts can be molded directly into the PTFE bellow. These inserts provide structural integrity and a robust flange or mounting point.

### Bellows from PTFE Compound

To enhance mechanical properties like wear resistance and compressive strength, PTFE can be blended with other materials. A common reinforcement is PEEK (Polyetheretherketone), which results in a bellow that retains chemical resistance while handling greater mechanical stress.

Understanding the Trade-offs

Selecting a bellow requires balancing competing characteristics. There is no single "best" type; there is only the best fit for a specific set of operational parameters.

### Flexibility vs. Pressure Handling

There is a direct trade-off between a bellow's flexibility and its ability to withstand pressure. Sharp fold bellows are highly flexible but perform poorly under pressure. Conversely, angular fold bellows offer superior pressure stability at the cost of reduced flexibility.

### Material Purity vs. Mechanical Strength

Pure, virgin PTFE offers the highest chemical resistance and purity. However, it is a relatively soft material. Adding fillers like PEEK or incorporating metal inserts dramatically improves mechanical strength and durability but may not be suitable for the most sensitive high-purity or pharmaceutical applications.

### Customization and Cost

A standard round or sharp fold bellow is a common component. However, bellows designed with integrated metal flanges, special compounds, or unique geometries are custom-engineered parts. This customization increases performance but also leads to higher costs and longer lead times.

Making the Right Choice for Your System

Your final decision should be guided by the primary demand of your application.

- If your primary focus is high-frequency motion: Choose a sharp fold bellow for its unmatched flexibility and long cycle life in dynamic applications like solenoid valves.

- If your primary focus is stability under pressure: Select an angular fold bellow to ensure the walls remain rigid and do not collapse.

- If your primary focus is hygiene and cleanability: Use a round fold bellow to eliminate potential contamination points, especially in food or pharmaceutical processing.

- If your primary focus is withstanding high mechanical force: Opt for a reinforced bellow with metal inserts or a PTFE compound to prevent mechanical failure.

Ultimately, a successful system relies on choosing the bellow that is precisely engineered to withstand its specific combination of chemical, thermal, and mechanical stress.

Summary Table:

| Bellow Type | Key Feature | Primary Use Case |

|---|---|---|

| Round Fold | Smooth, rounded convolutions | Hygienic applications (Food, Pharma) |

| Angular Fold | Rigid, V-shaped folds | High-pressure stability |

| Sharp Fold | Tight, accordion-like folds | High-frequency motion (Solenoid valves) |

| Reinforced | Metal inserts or PEEK compound | High mechanical stress environments |

Need a PTFE Bellow Engineered for Your Specific Application?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom bellows for the semiconductor, medical, laboratory, and industrial sectors. Whether you require a standard design or a fully customized solution with precise fold geometry and reinforcement, our expertise in precision production ensures optimal performance under extreme chemical, thermal, and mechanical stress.

We deliver:

- Custom Fabrication: From prototypes to high-volume orders.

- Material Expertise: Virgin PTFE for purity or reinforced compounds for strength.

- Application-Focused Design: Tailored solutions for valves, pumps, and critical interfaces.

Let us help you select or design the perfect bellow for your system. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- In which aerospace applications are PTFE energized seals commonly used? Critical Seals for Extreme Environments

- What are the key features of PTFE? Unmatched Performance for Extreme Industrial Environments

- What is Teflon gland packing and why is it important? Ensure Leak-Free Sealing in Harsh Conditions

- What are the advantages of using glass as a filler in PTFE? Enhance Strength and Wear Resistance

- What are the advantages of polyester-filled PTFE? A Guide to Superior Wear & Load Performance

- What industrial applications commonly use PTFE packing? Essential Sealing Solutions for Demanding Industries

- What are the limitations of PTFE gaskets? Understanding Mechanical Weaknesses for Better Sealing

- How did PTFE lined butterfly valves address corrosion resistance challenges? Provide a Robust Barrier Against Corrosive Media