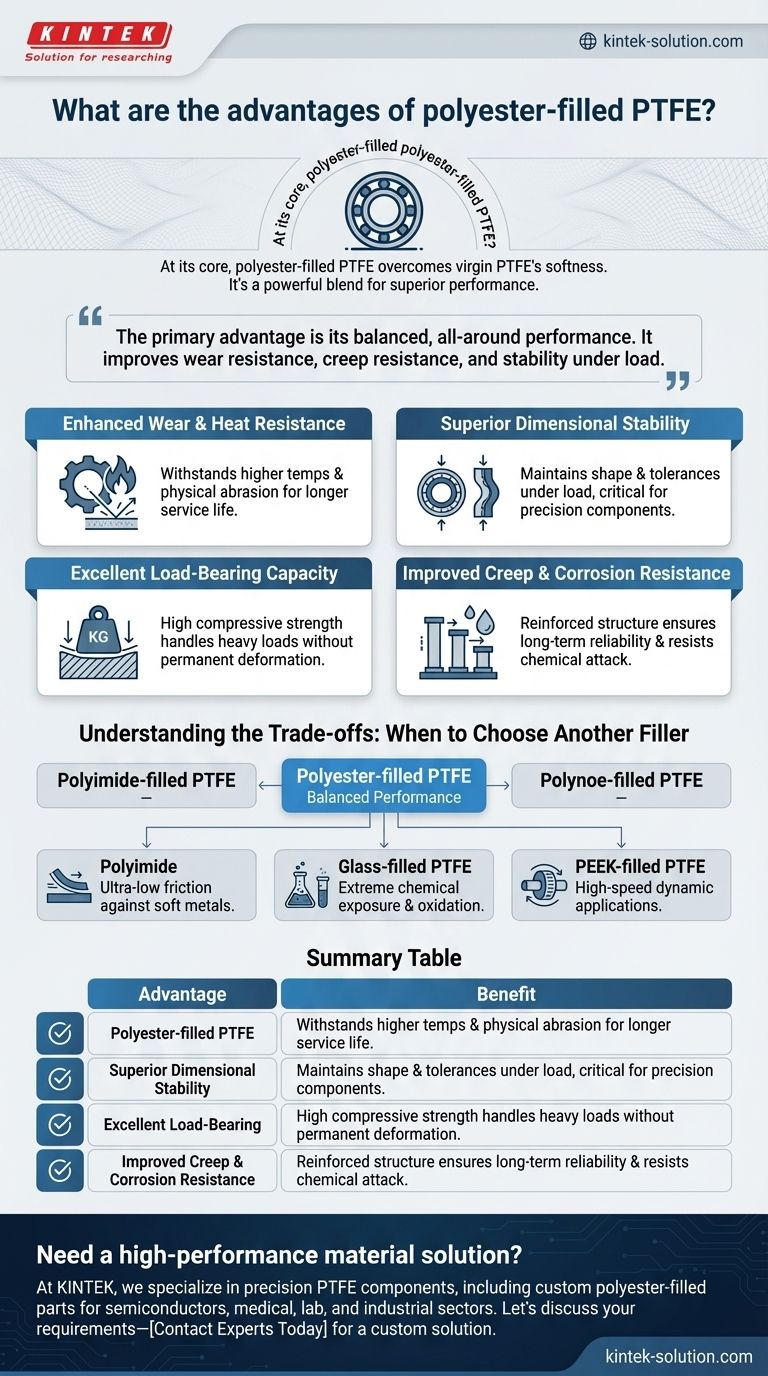

At its core, polyester-filled Polytetrafluoroethylene (PTFE) is engineered to overcome the inherent softness and deformation of virgin PTFE. It offers a powerful blend of superior heat resistance, dimensional stability, and excellent load-bearing capacity, making it a robust material for demanding mechanical applications like bearings and seals.

The primary advantage of polyester-filled PTFE is its balanced, all-around performance. It significantly improves wear resistance, creep resistance, and stability under load, establishing it as a go-to choice for general-purpose, high-stress components.

The Core Advantages of Polyester-Filled PTFE

Polyester is added to the PTFE matrix to fundamentally enhance its mechanical properties. This creates a composite material with capabilities far beyond those of unfilled PTFE.

Enhanced Wear and Heat Resistance

The addition of a polyester filler creates a much more durable material. It can withstand higher temperatures and resist physical abrasion far better than pure PTFE, leading to a longer service life in moving parts.

Superior Dimensional Stability

Unfilled PTFE can deform or "creep" over time, especially under a constant load or at elevated temperatures. Polyester-filled PTFE maintains its shape and tolerances much more effectively, which is critical for precision components like seals and bearings.

Excellent Load-Bearing Capacity

This material exhibits significantly higher compressive strength. It can handle heavy loads without being crushed or permanently deformed, a crucial attribute for any bearing or structural component.

Improved Creep and Corrosion Resistance

Creep is the tendency of a solid material to move slowly or deform permanently under the influence of persistent mechanical stresses. Polyester filler reinforces the PTFE structure, drastically reducing creep and ensuring long-term reliability. It also maintains PTFE's inherent resistance to corrosion.

Understanding the Trade-offs: When to Choose Another Filler

While polyester-filled PTFE is an excellent all-around performer, specific applications may demand a more specialized material. Understanding these alternatives clarifies where polyester truly excels.

When Friction is the Primary Concern

Polyimide-filled PTFE is the superior choice for applications where minimizing friction is the absolute priority. It is non-abrasive and ideal for use against softer mating surfaces like aluminum or plastics, especially in start-stop scenarios.

When Facing Extreme Chemical Exposure

Glass-filled PTFE offers enhanced chemical resistance, particularly in oxidizing environments. Its primary strengths are improved compression strength and wear resistance, making it suitable for aggressive chemical service.

When Dynamic Performance is Critical

For high-speed, dynamic applications, PEEK-filled PTFE often provides superior sliding properties and surface hardness. It offers a different profile of thermal and wear resistance tailored to constant motion.

Making the Right Choice for Your Application

Selecting the correct filled PTFE depends entirely on the primary challenge you need to solve.

- If your primary focus is balanced performance under high loads: Choose polyester-filled PTFE for its excellent all-around wear resistance, stability, and strength.

- If your primary focus is ultra-low friction against soft metals: Choose polyimide-filled PTFE to prevent abrasion and ensure smooth operation.

- If your primary focus is resistance to oxidizing chemicals: Choose glass-filled PTFE for its superior durability in harsh chemical environments.

- If your primary focus is high-speed dynamic applications: Evaluate PEEK-filled PTFE for its enhanced sliding properties and surface hardness.

Ultimately, understanding the unique strengths of each filler empowers you to select the precise material for optimal performance and longevity.

Summary Table:

| Key Advantage | Benefit |

|---|---|

| Enhanced Wear & Heat Resistance | Withstands higher temperatures and physical abrasion for longer service life. |

| Superior Dimensional Stability | Maintains shape and tolerances under load, critical for precision components. |

| Excellent Load-Bearing Capacity | High compressive strength handles heavy loads without permanent deformation. |

| Improved Creep & Corrosion Resistance | Reinforced structure ensures long-term reliability and resists chemical attack. |

Need a high-performance material solution for your demanding application?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom polyester-filled PTFE parts for seals, bearings, and other critical components in the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get the optimal material performance for superior wear resistance, stability, and longevity.

Let's discuss your specific requirements—contact our experts today for a custom solution from prototype to high-volume production.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments