In aerospace engineering, PTFE energized seals are critical components found in nearly every major aircraft system, from propulsion and flight controls to fuel and life support. They are specified for mission-critical applications including jet engine turbine seals, hydraulic flight control actuators, fuel pumps, and cryogenic propulsion lines where component failure is not an option.

The core reason for their widespread use is not simplicity, but resilience. PTFE energized seals are chosen specifically for applications where traditional elastomeric seals like O-rings would fail due to extreme temperatures, high pressures, aggressive chemicals, or high surface speeds.

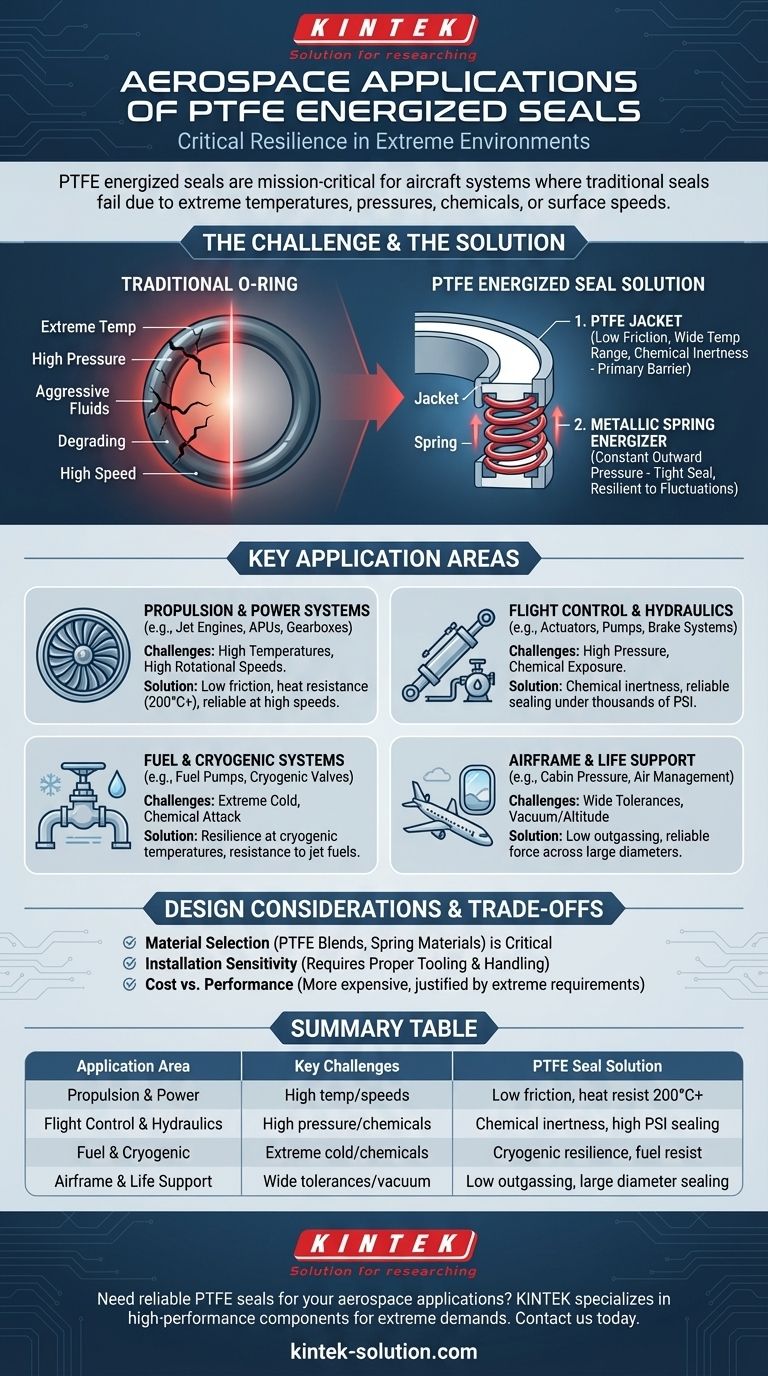

The Challenge: Sealing in Extreme Environments

Aerospace systems operate at the limits of material science. A seal on a landing gear strut must function perfectly at -50°C after hours at high altitude, while a turbine seal might see temperatures exceeding 200°C.

The Problem with Traditional Seals

Standard elastomeric seals (like nitrile or Viton™ O-rings) are excellent for many jobs, but they have limitations. They can become brittle at very low temperatures, degrade at high temperatures, and swell or break down when exposed to aggressive jet fuels and hydraulic fluids.

The PTFE Energized Seal Solution

This seal design overcomes these issues by combining two key parts:

-

A PTFE Jacket: Polytetrafluoroethylene (PTFE) is a polymer known for its incredibly low friction, wide operating temperature range, and near-universal chemical inertness. This jacket forms the primary sealing barrier.

-

A Metallic Spring Energizer: The PTFE jacket is rigid, so it needs help to maintain a positive sealing force. A metallic spring inside the jacket provides this constant outward pressure, ensuring a tight seal even at low pressures, during temperature fluctuations, or on slightly imperfect hardware surfaces.

Key Application Areas Breakdown

PTFE energized seals are found across the aircraft, segmented by the specific problem they solve.

Propulsion and Power Systems

These systems are defined by high temperatures and high rotational speeds. Applications include jet engines, auxiliary power units (APUs), starters, and gearboxes.

PTFE seals are used here as compressor and turbine seals, and in engine cooling and fuel lines. The low-friction PTFE jacket can handle surface speeds over 100 m/s, while the entire assembly withstands the intense heat radiating from the engine core.

Flight Control and Hydraulic Systems

These systems rely on high-pressure hydraulic fluid to move control surfaces. Key applications include actuators for flaps and landing gear, hydraulic pumps, and brake systems.

Here, the seal's chemical inertness is paramount, preventing degradation from aggressive hydraulic fluids. The spring energizer ensures a leak-free seal under thousands of PSI, providing the reliability needed for primary flight controls.

Fuel and Cryogenic Systems

Handling jet fuel and cryogenic propellants presents a dual challenge of chemical exposure and extreme cold. Applications include fuel pumps, injectors, quick-disconnects, and cryogenic valves.

PTFE's resistance to chemical attack is critical for sealing jet fuel. For cryogenic applications, the metallic spring energizer remains resilient at temperatures that would make elastomers shatter, ensuring a tight seal for liquid oxygen or hydrogen.

Airframe and Life Support Systems

These applications often involve sealing large diameters with significant pressure differentials. You will find them in air management systems and cabin pressure control systems.

The spring energizer provides a reliable sealing force across wide hardware tolerances typical of large airframe components. Furthermore, PTFE's low outgassing properties are crucial for maintaining air purity and functioning in the vacuum of high altitudes.

Understanding the Design Trade-offs

While highly capable, PTFE energized seals are not a universal solution. They are specialized components with specific considerations.

Material Selection is Everything

The "PTFE" jacket is often a blend of materials. Fillers like carbon, graphite, or glass are added to improve wear resistance and reduce creep, but they can alter chemical compatibility or friction properties. The spring energizer material (e.g., stainless steel, Elgiloy™) must also be chosen based on temperature and corrosive environment.

Installation Sensitivity

The PTFE jacket is a relatively soft plastic that can be scratched or gouged during installation. A damaged sealing lip can create a leak path, so proper tooling and careful handling are essential for a reliable seal.

Cost vs. Performance

These are complex, multi-component seals and are significantly more expensive than a simple O-ring. Their use is only justified when the performance requirements of temperature, pressure, speed, or chemical resistance exceed the capabilities of a less expensive solution.

Making the Right Choice for Your Application

Selecting the correct seal requires matching its properties to the primary challenge of the application.

- If your primary challenge is extreme temperature range: A PTFE energized seal is ideal for applications spanning from cryogenic fuels (-53°C) to hot engine components (+177°C and higher).

- If your primary challenge is high surface speed: Select a design with a low-friction PTFE compound to manage heat buildup in dynamic applications like gearboxes or turbine shafts.

- If your primary challenge is chemical compatibility: The inherent inertness of PTFE makes it the default choice for sealing aggressive jet fuels, hydraulic fluids, and de-icing agents.

- If your primary challenge is low pressure or vacuum: Ensure the spring energizer is robust enough to provide a positive sealing force when system pressure is not available to assist.

By understanding these core principles, you can confidently specify a sealing solution that ensures both performance and safety in the demanding aerospace environment.

Summary Table:

| Application Area | Key Challenges | PTFE Seal Solution |

|---|---|---|

| Propulsion & Power Systems | High temperatures, high speeds | Low friction, heat resistance up to 200°C+ |

| Flight Control & Hydraulic Systems | High pressure, chemical exposure | Chemical inertness, reliable sealing under thousands of PSI |

| Fuel & Cryogenic Systems | Extreme cold, chemical attack | Resilience at cryogenic temps, resistance to jet fuels |

| Airframe & Life Support | Wide tolerances, vacuum/altitude | Low outgassing, reliable sealing force across large diameters |

Need reliable PTFE seals for your aerospace applications? KINTEK specializes in manufacturing high-performance PTFE components, including energized seals, for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication—from prototypes to high-volume orders—ensure your components meet the strictest demands for extreme environments. Contact us today to discuss how we can support your critical sealing needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry