At its core, Teflon (PTFE) sheets are compatible with any project that requires a non-stick, heat-resistant, chemically inert, or electrically insulating surface. This versatility makes them valuable in applications ranging from T-shirt heat pressing and sublimation crafts to creating industrial-grade gaskets, seals, and low-friction bearings.

The key to understanding Teflon's compatibility is not to memorize a list of projects, but to recognize its three defining properties: an extremely low-friction (non-stick) surface, high heat resistance, and near-total chemical inertness. If your project demands one or more of these characteristics, a Teflon sheet is likely a suitable material.

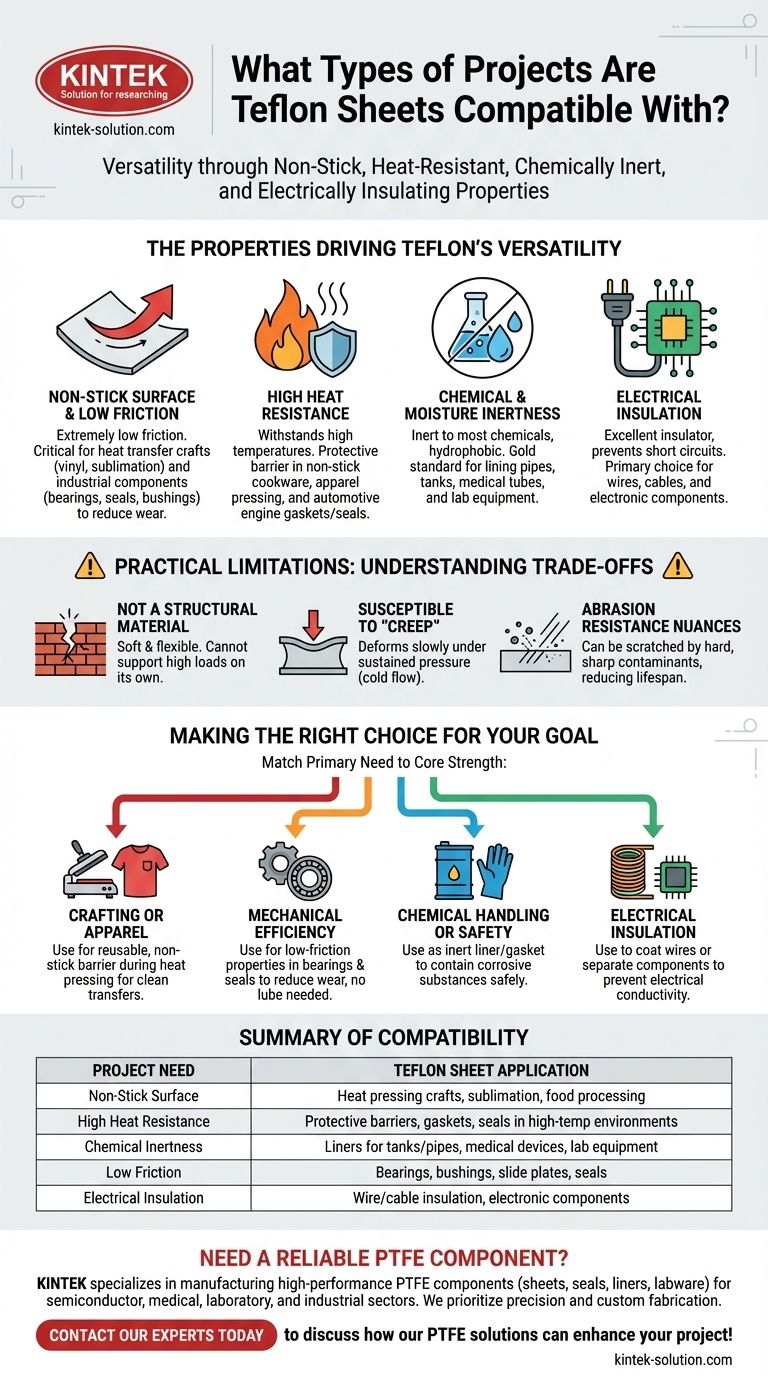

The Properties Driving Teflon's Versatility

A material's usefulness is a direct result of its inherent properties. Teflon's compatibility across consumer, commercial, and industrial sectors stems from a unique combination of characteristics.

The Impact of its Non-Stick Surface & Low Friction

Teflon is one of the most slippery materials known, giving it an exceptionally low coefficient of friction. This "non-stick" quality is its most famous attribute.

This property is critical for heat transfer crafts. When pressing heat transfer vinyl (HTV) or sublimation designs, a Teflon sheet prevents the hot plate from sticking to the vinyl or melting delicate fabrics, ensuring a clean transfer.

In industrial settings, this low friction reduces wear and tear on moving parts. It is used to create self-lubricating bearings, bushings, and seals in machinery and automotive components.

The Advantage of High Heat Resistance

Teflon can withstand high temperatures without degrading, a crucial feature for any application involving heat.

This allows it to act as a protective barrier between a heat source and a target material. It is used in non-stick cookware and as a protective sheet in apparel pressing to shield fabrics from direct, scorching heat.

In aerospace and automotive applications, its heat resistance makes it a reliable material for gaskets and seals in high-temperature engine environments.

The Importance of Chemical & Moisture Inertness

Teflon is almost completely inert, meaning it does not react with the vast majority of chemicals. It is also hydrophobic, repelling water and moisture.

This chemical resistance makes it the gold standard for lining pipes, tanks, and vessels that store or transport corrosive chemicals.

Its inertness is also vital in the medical field. It is used to make catheters, surgical tools, and medical tubes because it will not react with bodily fluids or cleaning agents.

The Role of Electrical Insulation

Teflon is an excellent electrical insulator, meaning it does not conduct electricity.

This property makes it a primary choice for insulating electrical wires, cables, and electronic components, preventing short circuits and ensuring safe operation, especially in high-performance applications.

Understanding the Practical Limitations

While incredibly versatile, Teflon is not the solution for every problem. Understanding its trade-offs is crucial for successful application.

It Is Not a Structural Material

Teflon is a relatively soft and flexible material. It should not be used for components that require high rigidity or load-bearing strength on their own.

It excels as a coating, liner, or interface material, but it is not a replacement for metal or hard plastics in structural roles.

It Is Susceptible to "Creep"

Under sustained pressure, especially at elevated temperatures, Teflon can slowly deform or "creep." This phenomenon, also known as cold flow, must be considered in designs for high-pressure seals and gaskets.

Its Abrasion Resistance Has Nuances

While its low friction reduces wear on parts sliding against it, Teflon itself is a soft material that can be scratched or abraded by hard, sharp particles.

In environments with abrasive contaminants, its lifespan as a bearing or seal surface may be limited compared to harder materials.

Making the Right Choice for Your Goal

To determine if Teflon is right for you, match your project's primary need to the material's core strengths.

- If your primary focus is crafting or apparel: Use Teflon sheets as a reusable, non-stick protective barrier during heat pressing to prevent scorching and ensure clean transfers.

- If your primary focus is mechanical efficiency: Use Teflon for its low-friction properties in bearings, seals, or slide plates to reduce wear and eliminate the need for liquid lubricants.

- If your primary focus is chemical handling or safety: Use Teflon as an inert liner or gasket material to safely contain corrosive substances without risk of reaction or degradation.

- If your primary focus is electrical insulation: Use Teflon to coat wires or separate components to prevent electrical conductivity and ensure reliable performance.

Ultimately, Teflon's value lies in its ability to provide a protective, non-reactive, and low-friction interface in environments where other materials would fail.

Summary Table:

| Project Need | Teflon Sheet Application |

|---|---|

| Non-Stick Surface | Heat pressing crafts, sublimation, food processing |

| High Heat Resistance | Protective barriers, gaskets, seals in high-temp environments |

| Chemical Inertness | Liners for tanks/pipes, medical devices, lab equipment |

| Low Friction | Bearings, bushings, slide plates, seals |

| Electrical Insulation | Wire/cable insulation, electronic components |

Need a reliable PTFE component for your specialized application?

KINTEK specializes in manufacturing high-performance PTFE components—including custom sheets, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We prioritize precision and offer custom fabrication from prototypes to high-volume orders to meet your exact requirements.

Contact our experts today to discuss how our PTFE solutions can enhance your project's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the advantages of PTFE as a sealing material? Superior Performance in Extreme Conditions

- What are the main machining techniques used for PTFE? Achieve Precision with CNC Turning, Milling & More

- What role does PTFE packing play in the pharmaceutical industry? Ensuring Drug Purity and Equipment Reliability

- What are the key steps in the manufacturing process of PTFE coated fasteners? Build a Durable, Corrosion-Resistant Shield

- Why are pressure conditions important when choosing PTFE packing? Ensure a Reliable Seal for Your System

- What are the preparation steps before using PTFE heat press sheets? Ensure Flawless Transfers Every Time

- How is Teflon used in cookware? Leveraging Non-Stick Properties for Superior Cooking

- In which industries are PTFE bellows commonly used due to their chemical resistivity? Essential for Corrosive & Pure Environments