In the pharmaceutical industry, PTFE packing and components serve as critical sealing and contact materials that guarantee product purity, prevent contamination, and ensure equipment reliability. Its selection is driven by its unique combination of chemical inertness, low-friction properties, and compliance with stringent FDA safety standards.

The core function of PTFE in pharmaceuticals is not merely to seal equipment, but to act as a barrier of purity. It ensures that the manufacturing process itself does not compromise the integrity or safety of the final drug product, a non-negotiable requirement in this highly regulated field.

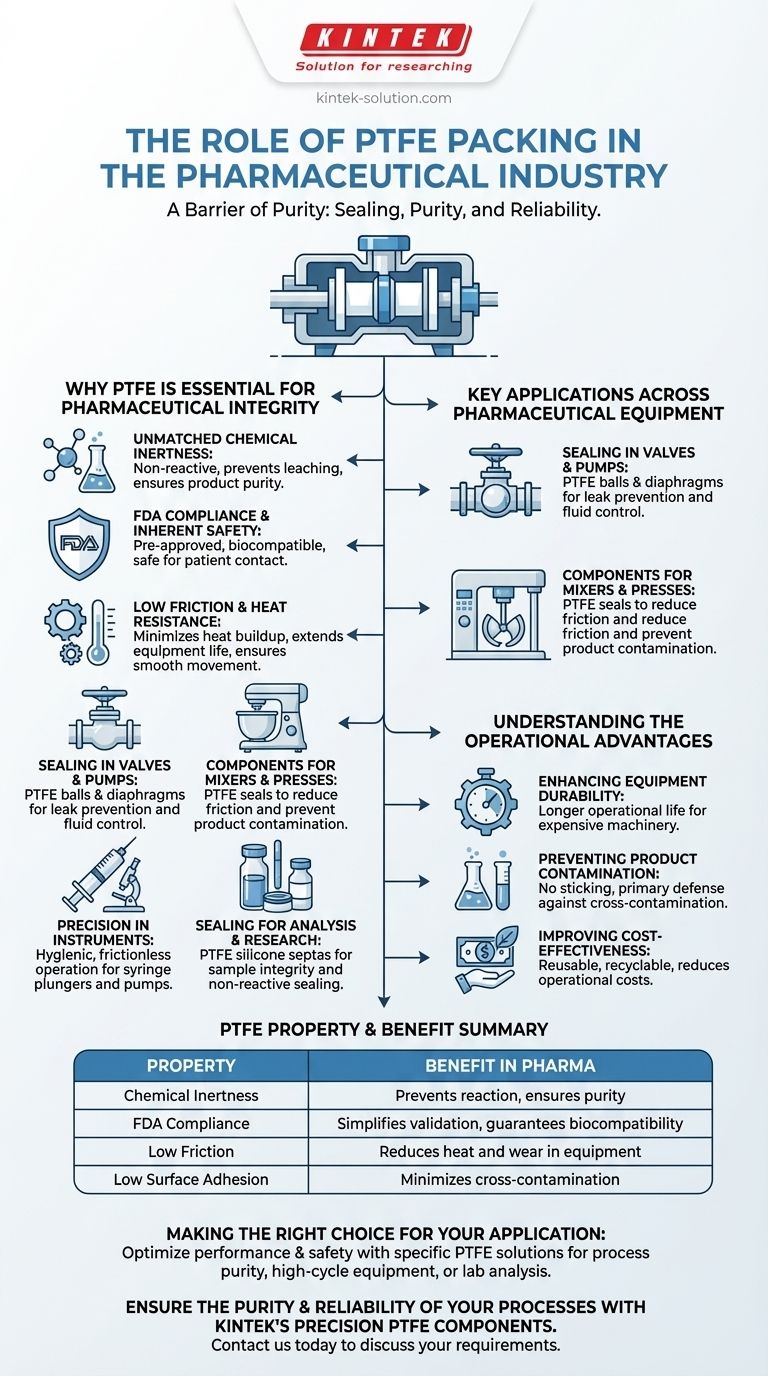

Why PTFE is Essential for Pharmaceutical Integrity

The prevalence of Polytetrafluoroethylene (PTFE), often known by the brand name Teflon, is a direct result of its ability to meet the uncompromising demands of pharmaceutical production. Its material properties are uniquely suited for environments where purity is paramount.

Unmatched Chemical Inertness

PTFE is virtually non-reactive with the vast majority of chemicals. This makes it an ideal material for handling the strong oxidizers, acidic compounds, and alkaline solvents common in drug formulation.

This inertness prevents the material from leaching into or reacting with sensitive drug compounds, which is critical for maintaining the purity of the final product and ensuring accurate analytical results in research.

FDA Compliance and Inherent Safety

PTFE is approved by the FDA for use in pharmaceutical applications. This pre-approved status simplifies regulatory compliance and equipment validation processes.

Crucially, it is biocompatible, meaning any microscopic debris that may result from seal wear can pass through the human body without consequence, adding a critical layer of patient safety.

Low Friction and Heat Resistance

In high-movement equipment like presses, pumps, and mixers, friction generates heat that can damage both the seal and the product. PTFE’s extremely low coefficient of friction minimizes this heat buildup.

This property ensures smooth, frictionless movement in delicate instruments like syringe plungers and extends the life of mechanical components, even under conditions of extreme heat.

Key Applications Across Pharmaceutical Equipment

PTFE is not a one-size-fits-all solution; it is engineered into specific components designed for distinct functions throughout the pharmaceutical manufacturing and research lifecycle.

Sealing in Valves and Pumps

PTFE balls and diaphragm valves are extensively used in fluid handling systems. They provide a perfect seal to prevent leaks while handling sensitive chemical compounds.

These components offer a high cycle life, chemical compatibility, and low surface adhesion, making them durable and cost-effective for controlling the flow of high-purity ingredients.

Components for Mixers and Presses

In equipment like mixers, presses, and bushings, PTFE seals are essential. They reduce friction during repetitive mechanical operations, preventing equipment damage and product spoilage.

When used in water-driven presses, these seals provide an added benefit: any potential leakage consists only of water, which will not contaminate the pharmaceutical product.

Precision in Laboratory Instruments

The hygienic and frictionless properties of PTFE are vital for laboratory equipment. It is used in syringe plungers, pump seals, and sample transport mechanisms to ensure smooth and precise operation.

Sealing for Analysis and Research

PTFE silicone septas are used to seal vials in research and quality control labs. Their chemical compatibility and ability to form a perfect seal protect sample integrity, preventing contamination that could invalidate analytical results.

Understanding the Operational Advantages

Beyond its material properties, the use of PTFE provides tangible benefits that impact operational efficiency, cost, and reliability.

Enhancing Equipment Durability

The low-friction and heat-resistant nature of PTFE reduces wear and tear on mechanical parts, leading to a longer operational life for expensive equipment like pumps and presses.

Preventing Product Contamination

The combination of chemical inertness and low surface adhesion means that drug formulations do not stick to or react with PTFE components, which is a primary line of defense against cross-contamination between batches.

Improving Cost-Effectiveness

Certain PTFE components, such as silicone septas, are designed to be reusable and recyclable. This helps reduce the operational costs and environmental footprint associated with disposable lab supplies without compromising quality.

Making the Right Choice for Your Application

Selecting the correct PTFE component is essential for optimizing performance and safety. Your decision should be guided by the specific demands of the equipment and process.

- If your primary focus is process purity and handling reactive chemicals: Utilize PTFE-lined valves, pumps, and diaphragms to ensure zero reaction with sensitive drug compounds.

- If your primary focus is high-cycle mechanical equipment: Choose PTFE seals and bushings for presses and mixers to minimize friction, heat, and wear.

- If your primary focus is laboratory analysis and sample integrity: Rely on PTFE silicone septas to provide a perfect, non-reactive seal for vials and containers.

Ultimately, PTFE is a foundational material that enables the pharmaceutical industry to manufacture safe, pure, and effective medicines with confidence.

Summary Table:

| Property | Benefit in Pharma |

|---|---|

| Chemical Inertness | Prevents reaction with drug compounds, ensuring purity |

| FDA Compliance | Simplifies validation and guarantees biocompatibility |

| Low Friction | Reduces heat and wear in pumps, presses, and mixers |

| Low Surface Adhesion | Minimizes cross-contamination between batches |

Ensure the purity and reliability of your pharmaceutical processes with KINTEK's precision PTFE components.

As specialists in custom PTFE fabrication for the semiconductor, medical, and laboratory industries, we understand the critical need for contamination-free sealing solutions. Our PTFE seals, liners, labware, and custom components are manufactured to the highest standards of precision and FDA compliance, protecting your sensitive drug formulations and extending equipment life.

Whether you need prototypes or high-volume orders for valves, pumps, septa, or custom parts, KINTEK delivers the material integrity and performance your application demands.

Contact us today to discuss your specific requirements and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- Can Teflon washers be used without lubricant? Yes, for Maximum Reliability and Low Maintenance

- What temperature range can ePTFE gaskets operate within? Seal from -200°C to 315°C

- What temperature range can PTFE expansion bellows withstand? Endure Extremes from -200°C to 260°C

- What makes PTFE O-Rings superior to those made of other materials? Unmatched Performance in Extreme Conditions

- How is PTFE extrusion molding performed and what are its applications? The Definitive Guide to High-Performance Components

- Why are pressure conditions important when choosing PTFE packing? Ensure a Reliable Seal for Your System

- What are the typical characteristics and applications of O-ring materials? Find the Right Seal for Extreme Environments

- What is a PTFE lined butterfly valve and what are its main advantages? Superior Control for Corrosive & High-Purity Fluids