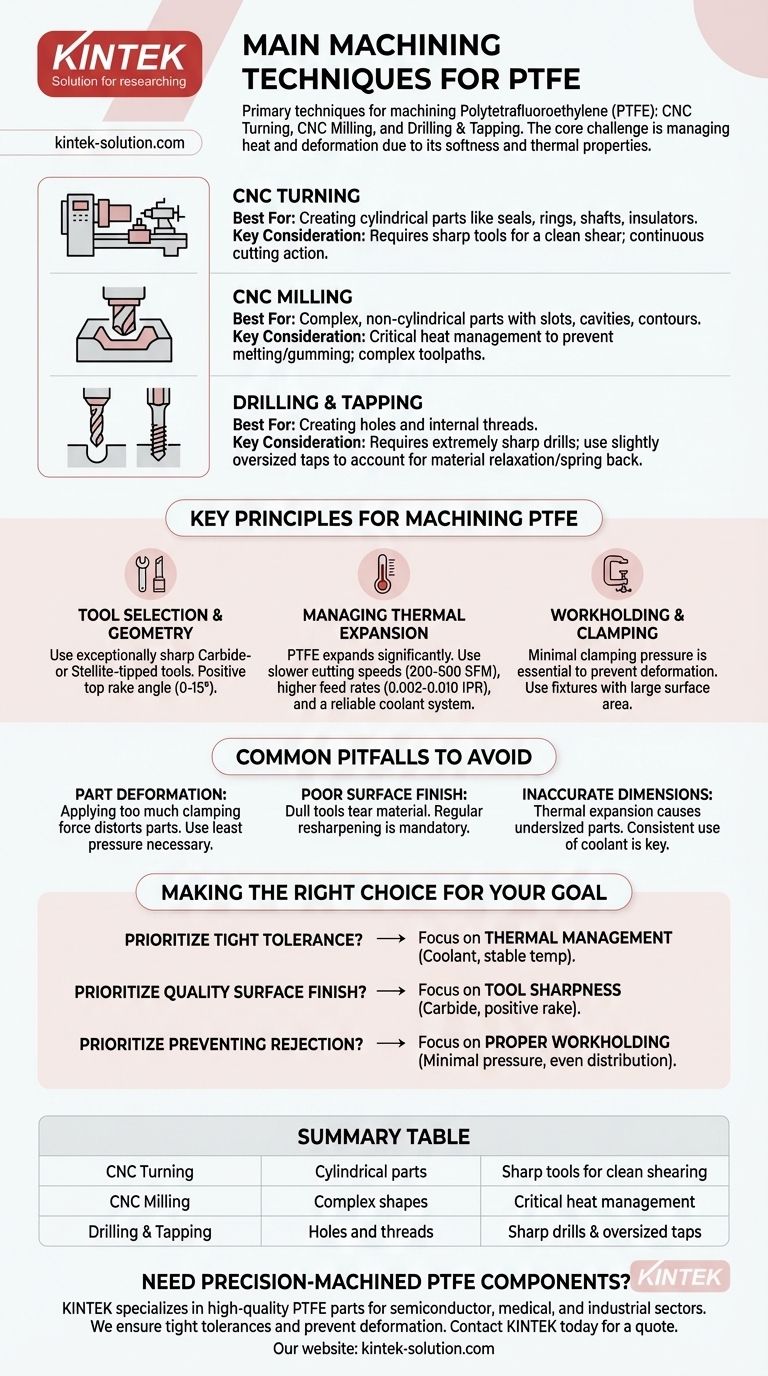

To machine Polytetrafluoroethylene (PTFE), the primary techniques are CNC turning, CNC milling, and drilling and tapping. CNC turning is ideal for creating cylindrical parts like seals and shafts, while CNC milling is used for more complex shapes with cavities and contours. Drilling and tapping are standard operations for creating holes and threads within the material.

The core challenge in machining PTFE is not its hardness, but its softness, high thermal expansion rate, and low thermal conductivity. Success depends entirely on managing heat buildup and physical deformation through sharp tooling, appropriate speeds, and minimal clamping pressure.

Understanding the Core Machining Processes

The right process depends entirely on the desired geometry of the final part. All standard equipment can be used, but the approach must be adapted for PTFE's unique properties.

CNC Turning

CNC turning involves rotating a PTFE rod while a cutting tool removes material to create a cylindrical profile. This method is highly efficient for producing parts like rings, seals, shafts, and insulators.

The continuous cutting action requires careful management of tool sharpness to ensure a clean shear rather than pushing or tearing the material.

CNC Milling

CNC milling uses a rotating multi-point cutting tool to remove material from a stationary workpiece. It is the preferred method for producing complex, non-cylindrical parts with features like slots, pockets, and intricate surface contours.

Because of the potential for complex toolpaths, managing heat at the cutting point is critical to prevent the material from melting or gumming up the tool.

Drilling and Tapping

Drilling creates holes, and tapping creates internal threads. While seemingly simple, these operations demand specific considerations for PTFE due to its elasticity and tendency to "spring back."

Drills must be extremely sharp to cleanly sever fibers. When tapping, it is often necessary to use a slightly oversized tap because the material will relax and shrink slightly after the tool is removed, resulting in a smaller final thread diameter.

Key Principles for Machining PTFE

Unlike metals, machining PTFE is a battle against heat and deformation, not material hardness. Its unique properties demand a specific approach to tooling and machine parameters.

Tool Selection and Geometry

The right tool is the most critical factor for a quality finish. Tools must be exceptionally sharp to slice the material cleanly.

Carbide-tipped or Stellite-tipped tools are highly recommended for their ability to hold a sharp edge and resist wear. A positive top rake angle (between 0 and 15 degrees) helps reduce cutting forces and minimizes friction.

Managing Thermal Expansion

PTFE expands and contracts significantly with temperature changes and has poor thermal conductivity, meaning heat stays concentrated at the cutting site.

Slower cutting speeds (200 to 500 surface feet per minute) combined with higher feed rates (0.002 to 0.010 inches per revolution) help reduce frictional heat. The tool spends less time rubbing in one spot, and a larger chip carries more heat away from the workpiece.

The use of a coolant system is highly advised to dissipate heat and prevent the material from expanding and compromising dimensional accuracy.

Workholding and Clamping

PTFE is a soft material that will easily deform under pressure. This is a common source of failed parts.

Minimal clamping pressure is essential to hold the workpiece securely without crushing or distorting it. Using fixtures with a larger surface area can help distribute the clamping force more evenly.

Common Pitfalls to Avoid

Understanding the potential issues before they arise is key to efficient and successful PTFE machining.

Part Deformation

The most common mistake is applying too much clamping force, which distorts the part. When the part is released, it springs back, and the machined dimensions will be incorrect. Always use the least amount of pressure necessary.

Poor Surface Finish

A dull cutting tool will not shear the PTFE; it will tear or push it. This results in a fuzzy or rough surface finish. Regular inspection and resharpening of tools are mandatory.

Inaccurate Dimensions

Failing to account for thermal expansion is a primary cause of dimensional inaccuracy. Machining a part while it is warm will result in an undersized part once it cools to ambient temperature. Consistent use of coolant is the best solution.

Making the Right Choice for Your Goal

Your specific objective will determine which machining principles you should prioritize.

- If your primary focus is tight dimensional tolerance: Prioritize thermal management above all else. Use a reliable coolant system and allow the material to stabilize at a consistent temperature before making finishing cuts.

- If your primary focus is a high-quality surface finish: Your top priority is tool sharpness. Use dedicated, freshly sharpened carbide tools with a positive rake and avoid dwelling the tool in any single spot.

- If your primary focus is preventing part rejection: Concentrate on proper workholding. Design fixtures that support the part without distorting it and instruct machinists to use minimal, evenly distributed clamping pressure.

Ultimately, treating PTFE as a unique material, rather than a soft metal, is the key to producing accurate, high-quality components.

Summary Table:

| Machining Technique | Best For | Key Considerations |

|---|---|---|

| CNC Turning | Cylindrical parts (seals, shafts, rings) | Continuous cutting; requires sharp tools for clean shearing. |

| CNC Milling | Complex shapes (slots, pockets, contours) | Critical heat management to prevent melting/gumming. |

| Drilling & Tapping | Creating holes and internal threads | Use sharp drills & slightly oversized taps for material relaxation. |

Need precision-machined PTFE components?

KINTEK specializes in manufacturing high-quality PTFE parts—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical principles of machining PTFE to prevent deformation and ensure tight tolerations.

Whether you need prototypes or high-volume orders, our expertise in custom fabrication delivers the reliability your application demands.

Contact KINTEK today for a quote and see how we can bring your PTFE project to life with precision and expertise.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments