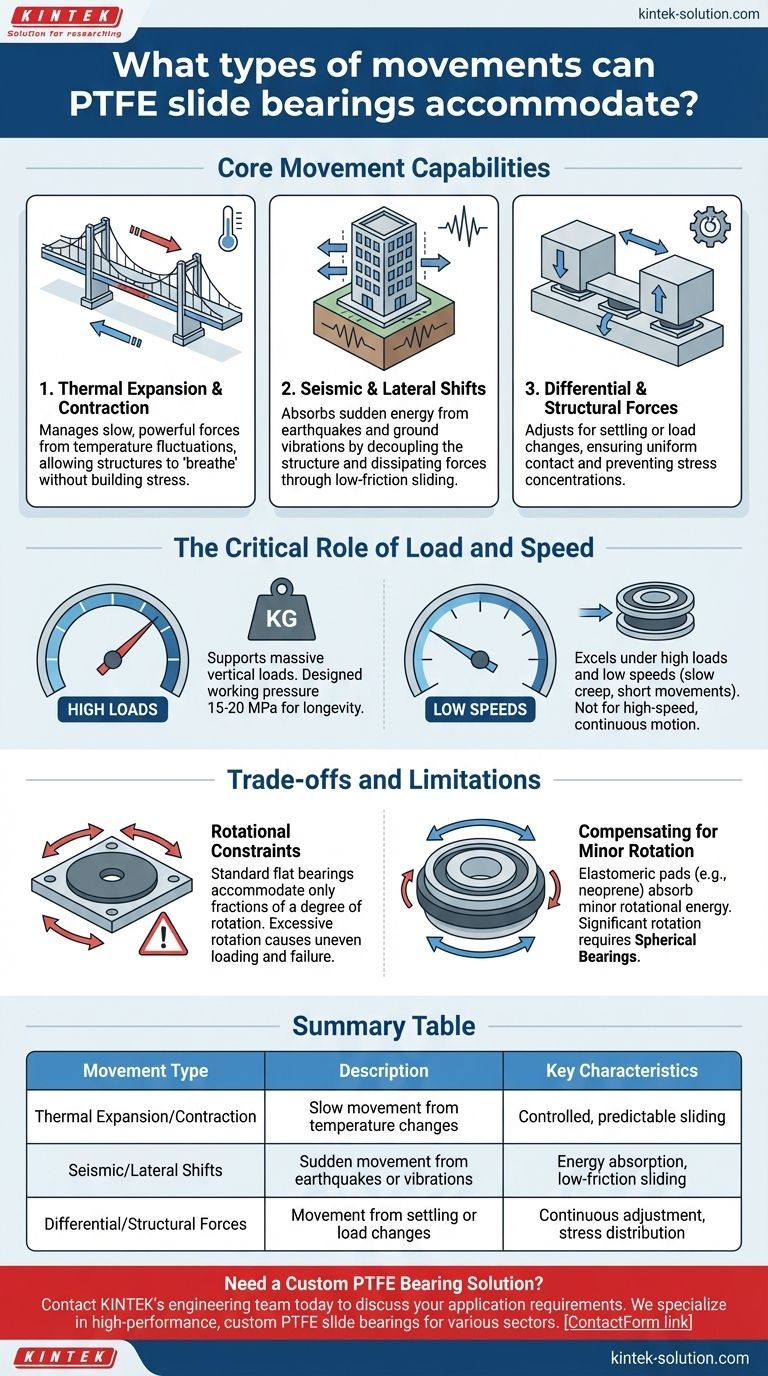

At their core, PTFE slide bearings are designed to accommodate three primary types of movement. They manage the slow, powerful forces of thermal expansion and contraction, absorb the sudden energy of seismic shifts, and adjust for differential movements caused by structural settling or load changes. These capabilities are enabled by creating a low-friction, high-load-capacity plane that allows a structure to move independently of its foundation.

The fundamental purpose of a PTFE slide bearing is to safely decouple a structure from its substructure. It achieves this by supporting an immense vertical load while simultaneously providing a near-frictionless surface for slow horizontal movement and minimal rotation, thereby isolating the structure from damaging stresses.

The Primary Modes of Movement Accommodated

PTFE slide bearings are not a universal solution for all types of motion. They are highly specialized components engineered to manage specific, predictable movements common in large-scale construction.

Thermal Expansion and Contraction

All large structures, from bridges to pipelines, expand and contract with temperature fluctuations.

A PTFE slide bearing provides a controlled surface for this slow, inevitable movement. This allows the structure to "breathe" without building up destructive internal stress.

Seismic and Lateral Shifts

During a seismic event, ground vibrations introduce powerful lateral and axial forces into a structure.

The low-friction surface of the bearing allows the structure to slide, absorbing and dissipating the seismic energy. This decoupling action prevents the shear forces from being transferred directly into the primary structural members.

Differential and Structural Forces

Over time, foundations can settle, or applied loads on a structure can shift.

PTFE bearings allow for small, continuous adjustments, ensuring that components remain in full contact and that loads are distributed as intended, preventing stress concentrations.

The Critical Role of Load and Speed

Understanding the intended operating conditions of these bearings is crucial. Their performance is defined by their ability to handle extreme pressure at very low velocities.

Designed for High Loads

The primary function of a slide bearing is to support a massive vertical load. The horizontal movement is a secondary, albeit critical, capability.

While PTFE material can technically handle compressive loads up to 40 MPa (400 Bar), a significant safety factor is always applied. Designs typically limit the working pressure to between 15 and 20 MPa to ensure longevity.

Optimized for Low Speeds

These bearings excel under high loads and low speeds. This is the environment where PTFE's self-lubricating properties are most effective.

They are engineered for the slow creep of thermal expansion or the short, sharp movements of an earthquake, not for high-speed, continuous motion found in rotating machinery.

Understanding the Trade-offs and Limitations

While exceptionally effective, PTFE slide bearings have clear limitations that must be respected in any design. The most significant of these is their capacity for rotation.

Rotational Constraints

A standard flat PTFE slide bearing is not designed for rotation. It can typically only accommodate fractions of a degree of misalignment or rotation.

Forcing rotation on a standard bearing can cause uneven loading, stress concentrations at the edges, and premature failure.

Compensating for Minor Rotation

For applications with predictable minor rotation, an elastomeric pad (made of materials like neoprene or silicone) can be integrated into the bearing assembly.

This pad compresses to absorb the rotational energy. However, increasing the elastomer thickness to handle more rotation can introduce stability issues.

Solutions for Significant Rotation

When an application requires significant rotational freedom, a standard slide bearing is the wrong component.

In these cases, a spherical bearing arrangement is the appropriate solution. These bearings are specifically designed to allow rotation on multiple axes while still supporting the primary vertical load.

Making the Right Choice for Your Application

Selecting the correct bearing configuration requires a clear understanding of the specific movements and forces your structure will face.

- If your primary focus is standard thermal or seismic movement: A standard PTFE plate bearing bonded to a steel backing plate is the most common and effective solution.

- If your primary focus is minor rotation (fractions of a degree): Specify a bearing assembly that incorporates an integrated elastomeric pad to absorb these forces.

- If your primary focus is operating in a high-temperature environment (above 130°C): Consider specialized options like PTFE recessed into the backing plate or a graphite-based sliding surface.

- If your primary focus is accommodating significant multi-axis rotation: A PTFE slide bearing is not suitable; your design requires a spherical bearing.

By correctly identifying the required movements, you can select a bearing system that ensures the long-term integrity and safety of your structure.

Summary Table:

| Movement Type | Description | Key Characteristics |

|---|---|---|

| Thermal Expansion/Contraction | Slow movement from temperature changes | Controlled, predictable sliding |

| Seismic/Lateral Shifts | Sudden movement from earthquakes or vibrations | Energy absorption, low-friction sliding |

| Differential/Structural Forces | Movement from settling or load changes | Continuous adjustment, stress distribution |

Need a Custom PTFE Bearing Solution for Your Project?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom slide bearings for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production ensures your bearings are engineered to handle specific movements, loads, and environmental conditions—from prototypes to high-volume orders.

Contact our engineering team today to discuss your application requirements and get a solution tailored for safety, longevity, and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the advantages of unreinforced PTFE laminates? Achieve Ultimate Signal Integrity for High-Frequency Designs

- Why is Teflon difficult to machine to tight tolerances? Overcome Material Instability

- How do PTFE envelope gaskets perform under high pressure and temperature conditions? Unlock Reliable Sealing in Harsh Environments

- What medical applications benefit from extruded PTFE rods? Precision Components for Surgical & Diagnostic Devices

- How can dimensional stability be maintained in machined PTFE parts? Master Precision Machining & Stress Relief

- What are the main applications of ePTFE sheets in the medical industry? From Grafts to Guided Regeneration

- What are the main advantages of PTFE diaphragm valves in the pharmaceutical industry? Ensure Purity, Sterility, and Reliability

- What are the advantages of PTFE lined diaphragm valves? Superior Corrosion & Purity Control