In the medical field, extruded PTFE rods are primarily machined into high-performance components for surgical instruments, medical devices, and testing equipment. Their value comes from a unique combination of extreme chemical resistance, biocompatibility, and low-friction properties that are critical in sterile environments.

The core decision is not just about choosing PTFE, but understanding its form. Solid extruded PTFE rods are the go-to material for durable, machined parts, while a different form, expanded PTFE (ePTFE), is required for implants that must integrate with human tissue.

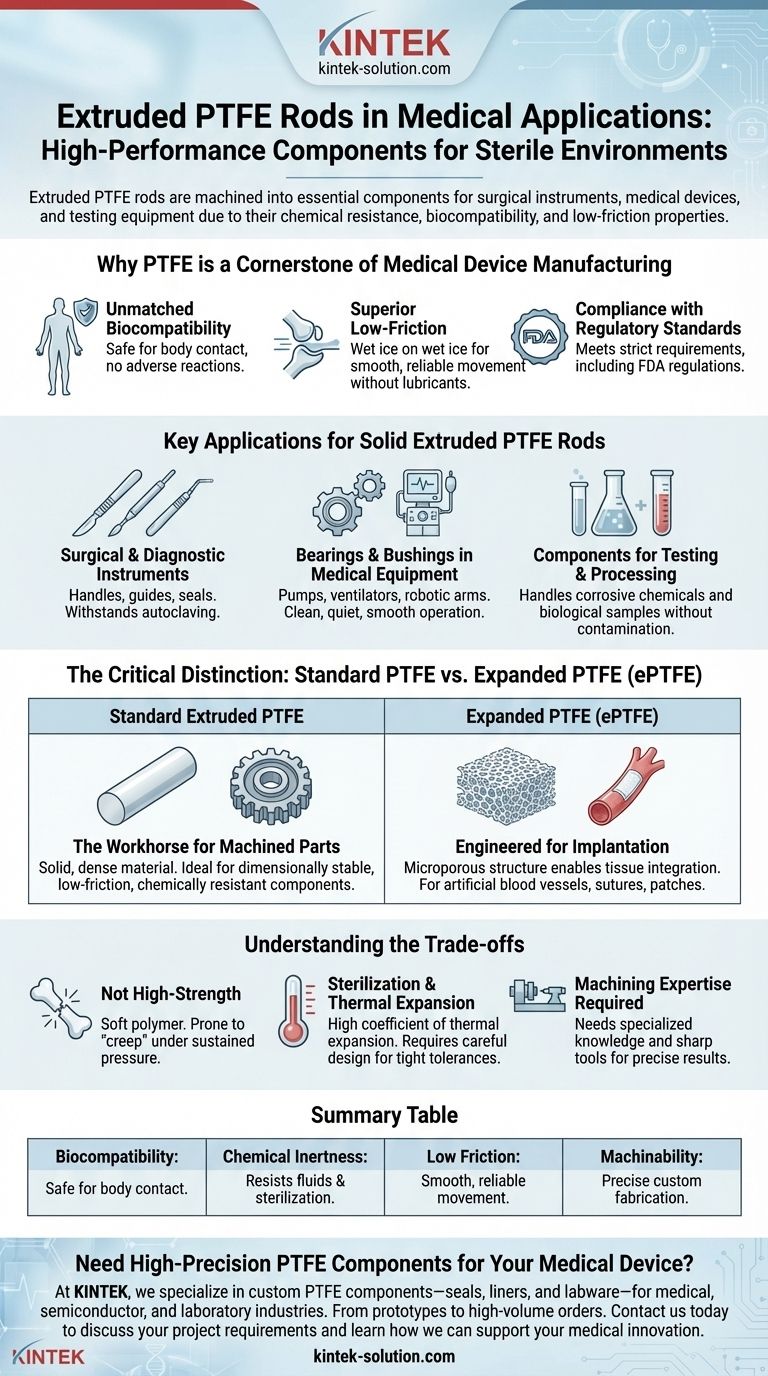

Why PTFE is a Cornerstone of Medical Device Manufacturing

Polytetrafluoroethylene (PTFE) is not just another polymer; its specific attributes make it uniquely suited for the demanding requirements of medical applications.

Unmatched Biocompatibility and Inertness

PTFE is highly biocompatible, meaning it does not cause adverse reactions when it comes to contact with the human body.

Its chemical inertness also ensures it will not degrade or react when exposed to bodily fluids or aggressive sterilization chemicals, guaranteeing material purity.

Superior Low-Friction Properties

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice.

This natural lubricity is essential for components in medical devices and surgical tools that require smooth, reliable movement without the need for external lubricants, which could be a source of contamination.

Compliance with Regulatory Standards

Medical-grade PTFE meets strict regulatory requirements, including compliance with FDA regulations. This is a non-negotiable prerequisite for any material intended for use in medical devices or equipment.

Key Applications for Solid Extruded PTFE Rods

Solid PTFE rods serve as the raw material stock for CNC machining, allowing for the precise fabrication of custom components.

Surgical and Diagnostic Instruments

Rods are machined to create handles, guides, seals, and other parts of surgical instruments. The material's ability to withstand repeated sterilization cycles (autoclaving) is critical here.

Bearings and Bushings in Medical Equipment

PTFE is used for bearings and bushings in medical equipment like pumps, ventilators, and robotic surgical arms. These components ensure clean, quiet, and smooth operation over a long lifespan.

Components for Testing and Processing

In laboratory and testing equipment, PTFE parts are used to handle highly corrosive chemicals and biological samples without risk of corrosion or contamination.

The Critical Distinction: Standard PTFE vs. Expanded PTFE (ePTFE)

A common point of confusion is the difference between standard PTFE and its expanded variant, ePTFE. They serve fundamentally different medical purposes.

Standard PTFE: The Workhorse for Machined Parts

Extruded PTFE rods are a solid, dense material. They are ideal for creating dimensionally stable, low-friction, and chemically resistant components through machining. These parts are durable and non-porous.

Expanded PTFE (ePTFE): Engineered for Implantation

Expanded PTFE (ePTFE) is a specialized form of the material that has been stretched to create a microporous structure. This structure is the key to its most advanced medical applications.

This porosity allows human tissue and blood vessels to grow into the material, enabling tissue integration. This makes ePTFE the material of choice for implants like artificial blood vessels, surgical sutures, and patches for heart repair.

Understanding the Trade-offs

While exceptionally useful, PTFE is not a universal solution. Understanding its limitations is key to successful application.

Not a High-Strength Material

PTFE is a relatively soft polymer. It is not suitable for high-load structural applications where mechanical strength is the primary requirement, as it can be prone to "creep" or deformation under sustained pressure.

Sterilization and Thermal Expansion

PTFE can be safely sterilized in an autoclave, but it has a high coefficient of thermal expansion. This must be accounted for in the design of parts with tight tolerances to ensure they function correctly at different temperatures.

Machining Expertise Required

Because of its softness and tendency to deform under tool pressure, machining PTFE to precise tolerances requires specialized knowledge, sharp tools, and specific techniques to achieve accurate results.

Selecting the Right PTFE for Your Medical Application

Your end goal dictates which form of PTFE is appropriate.

- If your primary focus is creating durable, non-implantable device components: Standard extruded PTFE rods are the ideal choice for their machinability, inertness, and low-friction surface.

- If your primary focus is developing implants that integrate with the body: You must use expanded PTFE (ePTFE) for its microporous structure that encourages tissue ingrowth.

- If your primary focus is smooth, clean operation in medical machinery: PTFE-lined bearings or machined bushings provide unmatched low-friction performance without external lubricants.

Choosing the correct form of PTFE is fundamental to leveraging its unique properties for safe and effective medical outcomes.

Summary Table:

| Property | Benefit for Medical Applications |

|---|---|

| Biocompatibility | Safe for contact with the human body; does not cause adverse reactions. |

| Chemical Inertness | Resists bodily fluids and sterilization chemicals; ensures material purity. |

| Low Friction | Provides smooth, reliable movement in devices without contaminating lubricants. |

| Machinability | Allows for precise fabrication of custom components from solid rods. |

Need High-Precision PTFE Components for Your Medical Device?

At KINTEK, we specialize in manufacturing custom PTFE components—including seals, liners, and labware—for the medical, semiconductor, and laboratory industries. Our expertise in precision machining ensures your devices meet the highest standards for performance and safety.

We offer custom fabrication from prototypes to high-volume orders, ensuring you get the exact components you need.

Contact us today to discuss your project requirements and learn how we can support your medical innovation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs