In the pharmaceutical industry, the primary advantages of PTFE diaphragm valves are their exceptional chemical inertness, inherent purity, and robust physical durability. These characteristics ensure that high-purity media remain uncontaminated, sterile processes are maintained without risk of microbial growth, and operational reliability is maximized through high cycle life and minimal maintenance.

The choice of a PTFE diaphragm valve is not merely a component selection; it is a strategic decision to safeguard product integrity and ensure process reliability. Its unique combination of chemical non-reactivity and a smooth, crevice-free design directly mitigates the core risks of contamination and operational downtime in sensitive pharmaceutical manufacturing.

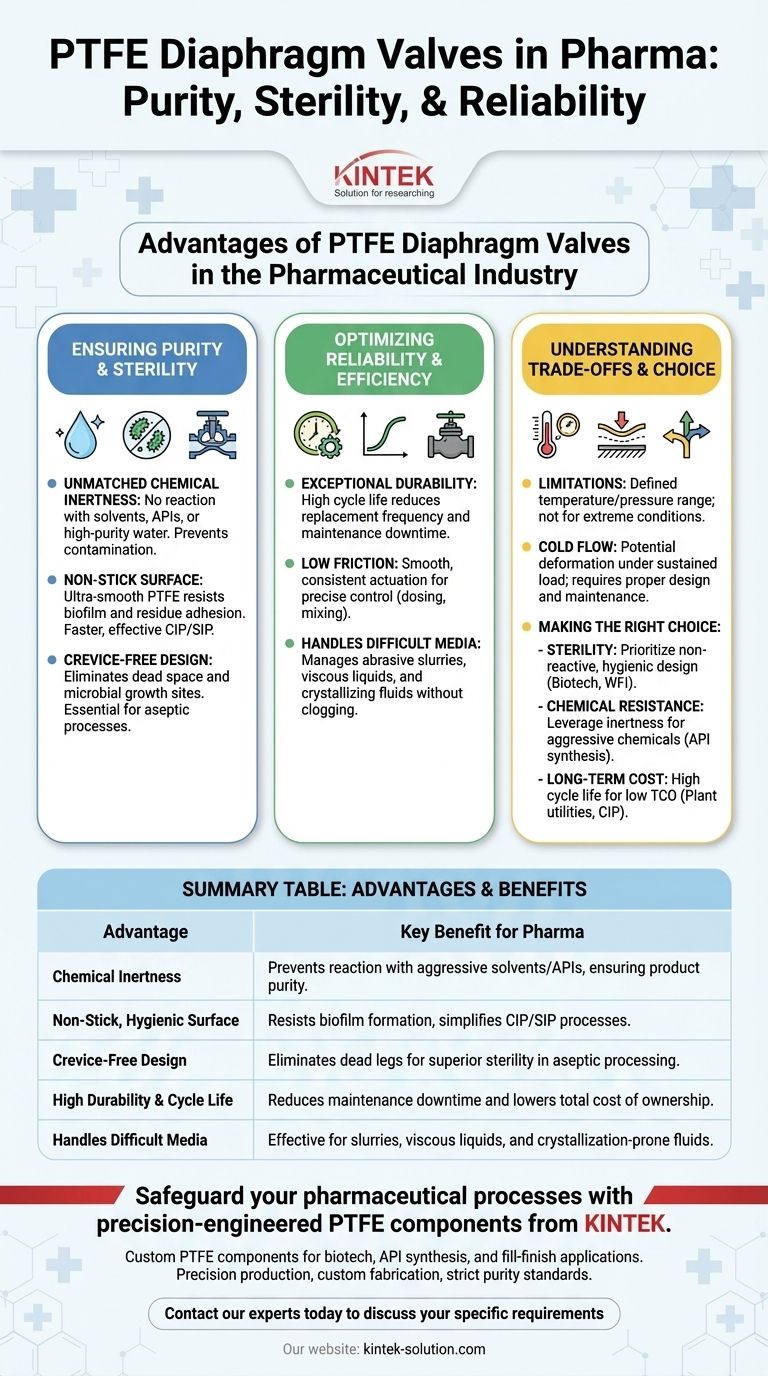

Ensuring Absolute Product Purity and Sterility

The fundamental challenge in pharmaceutical processing is preventing any alteration of the product. PTFE diaphragm valves are specifically engineered to address this at a material level.

Unmatched Chemical Inertness

PTFE (Polytetrafluoroethylene) is one of the most non-reactive materials known. It will not react with, corrode from, or leach into the aggressive solvents, APIs, or high-purity water used in pharmaceutical production.

This inertness is critical for preventing contamination and ensuring the final product meets stringent regulatory standards for purity.

Non-Stick Surface for Hygienic Operation

The surface of PTFE is extremely smooth and has very low adhesion, often described as "non-stick." This property is vital for preventing biofilms or product residue from adhering to the valve's surface.

This makes Clean-in-Place (CIP) and Sterilize-in-Place (SIP) processes faster, more effective, and more reliable, as there are no microscopic sites for bacteria to colonize.

Crevice-Free and No-Pocket Design

High-quality diaphragm valves are designed to be "no-pocket" and crevice-free. The flexible PTFE diaphragm seals directly against the valve body, eliminating any dead space where media could stagnate and foster microbial growth.

This design is essential for maintaining sterility in aseptic processes, from biotech applications to final fill-finish lines.

Optimizing Operational Reliability and Efficiency

Beyond purity, these valves contribute directly to a more efficient and cost-effective operation by reducing downtime and maintenance demands.

Exceptional Durability and High Cycle Life

PTFE is a highly durable material that withstands repeated actuation and flexing. This translates to a very high cycle life for the diaphragm, reducing the frequency of replacement.

Fewer maintenance interventions mean less process downtime, lower labor costs, and reduced risk of introducing contamination during servicing.

Low Friction for Precise Control

The low coefficient of friction of PTFE allows the valve to actuate smoothly and consistently. This is beneficial for applications requiring precise flow control or throttling, such as in dosing or media mixing.

Reliable actuation ensures process parameters remain stable, contributing to batch-to-batch consistency.

Handling Difficult Media

The combination of chemical resistance and a flexible diaphragm makes these valves ideal for handling challenging fluids. They can effectively manage abrasive slurries, viscous liquids, or media prone to crystallization without clogging or damage.

Understanding the Trade-offs

While highly advantageous, it is important to understand the operational limits of PTFE to ensure correct application.

Temperature and Pressure Limitations

PTFE has a defined operational temperature and pressure range. Compared to all-metal valves, it cannot handle extremely high temperatures or pressures. Exceeding these specifications can compromise the integrity of the diaphragm seal.

Potential for "Cold Flow"

Under sustained mechanical load or pressure, PTFE can exhibit a property known as "cold flow" or creep, where the material slowly deforms over time. This must be accounted for in valve design and bolt-torquing procedures to ensure a long-lasting, leak-free seal.

Initial Cost Considerations

The initial procurement cost of a high-purity PTFE diaphragm valve can be higher than that of simpler valve types. However, this cost is often justified by a lower total cost of ownership (TCO) when factoring in reduced maintenance, less downtime, and mitigated risk of batch contamination.

Making the Right Choice for Your Process

Selecting a valve requires matching its strengths to your primary process goal.

- If your primary focus is sterility and purity (e.g., biotech, WFI systems, fill-finish): Prioritize the valve's non-reactive, non-stick, and crevice-free hygienic design to eliminate any risk of contamination.

- If your primary focus is handling aggressive chemicals (e.g., API synthesis, chemical dosing): Leverage PTFE's unmatched chemical resistance to ensure long-term valve integrity and operator safety.

- If your primary focus is long-term cost and reliability (e.g., plant utilities, CIP skids): The valve's high cycle life and low maintenance requirements will deliver the best total cost of ownership.

Ultimately, specifying a PTFE diaphragm valve is an investment in predictable, compliant, and contamination-free pharmaceutical manufacturing.

Summary Table:

| Advantage | Key Benefit for Pharma |

|---|---|

| Chemical Inertness | Prevents reaction with aggressive solvents and APIs, ensuring product purity. |

| Non-Stick, Hygienic Surface | Resists biofilm formation and simplifies CIP/SIP processes. |

| Crevice-Free Design | Eliminates dead legs for superior sterility in aseptic processing. |

| High Durability & Cycle Life | Reduces maintenance downtime and lowers total cost of ownership. |

| Handles Difficult Media | Effective for slurries, viscous liquids, and crystallization-prone fluids. |

Safeguard your pharmaceutical processes with precision-engineered PTFE components from KINTEK.

Are you looking for reliable, high-purity valves for your biotech, API synthesis, or fill-finish applications? KINTEK specializes in manufacturing custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring your systems meet the strictest purity and sterility standards.

Contact our experts today to discuss your specific requirements and discover how our PTFE solutions can enhance your operational reliability and product integrity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What makes Teflon suitable for use in bearings and similar applications? Discover Its Low-Friction, Chemical-Resistant Advantages

- What are some common grades of PTFE used in fabrication? Choose the Right Material for Your Application

- Why are PTFE spring energized seals preferred in the oil and gas industry? Unmatched Resilience for HPHT & Corrosive Environments

- How does the PTFE lining in diaphragm valves enhance performance? Boost Reliability in Harsh Chemical Processes

- What factors should be considered when choosing between NBR and PTFE seat materials for butterfly valves?

- What configurations are available for PTFE rotary shaft seals? Optimize Performance with Lip, Shell & Material Options

- What are the main benefits of PTFE slide bearings? A Low-Maintenance, High-Performance Alternative

- How is the PTFE sheet positioned during the heat transfer process? Ensure a Perfect, Protected Press Every Time