At a glance, PTFE envelope gaskets perform exceptionally well under a wide range of high-pressure and high-temperature conditions. Their unique combination of a chemically inert PTFE shell and a resilient inner core allows them to maintain seal integrity where many other materials would fail, exhibiting low leakage rates and excellent resistance to harsh environments.

The true performance of a PTFE envelope gasket is not defined by its impressive temperature range alone, but by the interplay between temperature, pressure, and time. While its chemical and thermal resistance is top-tier, understanding its mechanical limitations at the upper end of its operating range is critical to preventing seal failure.

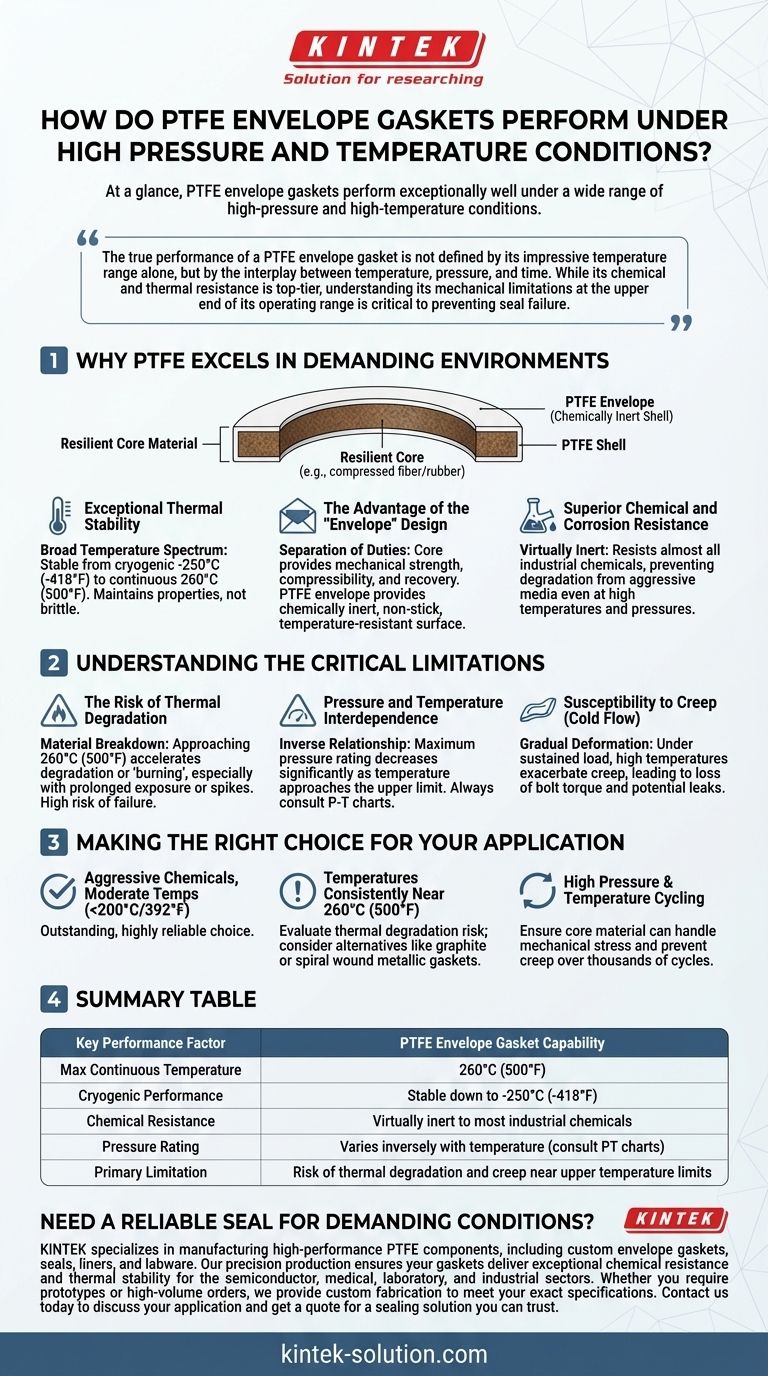

Why PTFE Excels in Demanding Environments

The effectiveness of a PTFE envelope gasket stems from a design that leverages the best properties of multiple materials. The Polytetrafluoroethylene (PTFE) provides the critical sealing surface, while a separate core material provides the mechanical strength.

### Exceptional Thermal Stability

PTFE is renowned for its ability to function across an extremely broad temperature spectrum. It remains stable and effective in continuous service at temperatures up to 260°C (500°F).

Equally impressive is its performance in cryogenic conditions, maintaining its properties in temperatures as low as -250°C (-418°F) without becoming brittle.

### The Advantage of the "Envelope" Design

The term "envelope" is key. The gasket consists of a resilient core material (like compressed non-asbestos fiber or rubber) that is fully enclosed in a thin shell, or envelope, of PTFE.

This design brilliantly separates duties. The core provides the mechanical strength, compressibility, and recovery needed to create and maintain a tight seal under high flange pressure. The PTFE envelope provides the chemically inert, temperature-resistant, and non-stick surface that contacts the process fluid.

### Superior Chemical and Corrosion Resistance

PTFE is virtually inert to almost all industrial chemicals. This makes it an ideal choice for aggressive media, where high temperatures and pressures can often accelerate corrosion and material degradation. This property ensures the gasket's sealing surface does not degrade from chemical attack.

Understanding the Critical Limitations

While highly capable, PTFE is not infallible. Pushing the material beyond its design limits, particularly concerning temperature, can lead to failure. A clear understanding of its trade-offs is essential for reliable operation.

### The Risk of Thermal Degradation

The most significant limitation is material breakdown at extreme heat. As temperatures consistently approach the maximum continuous limit of 260°C (500°F), the PTFE can begin to degrade or "burn."

This process is accelerated with prolonged exposure. For applications involving large, hot areas or where temperatures may spike, the risk of gasket failure increases substantially.

### Pressure and Temperature Interdependence

A gasket's pressure rating is not a fixed number. It is inversely related to temperature. A PTFE envelope gasket that can handle very high pressure at ambient temperature will have a significantly lower maximum pressure rating as it approaches its upper temperature limit.

Engineers must always consult pressure-temperature charts for the specific gasket to ensure it is operating within its safe limits for the given conditions.

### Susceptibility to Creep (Cold Flow)

PTFE, being a thermoplastic, can be prone to "creep" — a gradual deformation under sustained compressive load. High temperatures exacerbate this tendency.

The core material inside the envelope is designed to mitigate this, but under conditions of high pressure and high temperature, creep can still lead to a loss of bolt torque and, eventually, a leak.

Making the Right Choice for Your Application

Selecting the correct gasket requires evaluating the complete operational context, not just a single temperature or pressure value.

- If your primary focus is aggressive chemical resistance at moderate temperatures (below 200°C / 392°F): A PTFE envelope gasket is an outstanding and highly reliable choice.

- If your application involves temperatures consistently approaching 260°C (500°F): You must carefully evaluate the risk of thermal degradation and consider alternative materials, such as graphite or spiral wound metallic gaskets.

- If your system experiences high pressure combined with significant temperature cycling: Pay close attention to the gasket's core material to ensure it can handle the mechanical stress and prevent creep over thousands of cycles.

Ultimately, leveraging the strengths of PTFE envelope gaskets requires respecting their well-defined operational boundaries.

Summary Table:

| Key Performance Factor | PTFE Envelope Gasket Capability |

|---|---|

| Max Continuous Temperature | 260°C (500°F) |

| Cryogenic Performance | Stable down to -250°C (-418°F) |

| Chemical Resistance | Virtually inert to most industrial chemicals |

| Pressure Rating | Varies inversely with temperature (consult PT charts) |

| Primary Limitation | Risk of thermal degradation and creep near upper temperature limits |

Need a reliable seal for demanding conditions?

KINTEK specializes in manufacturing high-performance PTFE components, including custom envelope gaskets, seals, liners, and labware. Our precision production ensures your gaskets deliver exceptional chemical resistance and thermal stability for the semiconductor, medical, laboratory, and industrial sectors.

Whether you require prototypes or high-volume orders, we provide custom fabrication to meet your exact specifications.

Contact us today to discuss your application and get a quote for a sealing solution you can trust.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- How can PTFE sheets be customized for specific industrial needs? Tailor Performance for Your Application

- What are some common applications of filled PTFE? Enhance Performance in Demanding Industries

- What are the pressure-temperature limitations for polymer seats in high performance butterfly valves? Avoid Costly Valve Failures

- What are the advantages of PTFE lined diaphragm valves? Superior Corrosion & Purity Control

- What are the features and applications of PTFE lip gaskets? A Guide to Sealing in Extreme Environments

- What precautions should be taken for maximum seal life expectancy? Follow the 75% Rule for Longevity

- What is the pH range for both PTFE and graphite packing? Selecting the Right Material for Extreme Conditions

- How can Teflon PTFE sheets assist in crafting with glue or resin? Achieve a Clean, Reusable Workspace