In short, PTFE lined diaphragm valves offer a powerful combination of exceptional chemical resistance, a hygienic crevice-free design, and superior leak prevention. This makes them a default choice for safely controlling fluids that are highly corrosive, demand extreme purity, or are prone to clogging standard valve types.

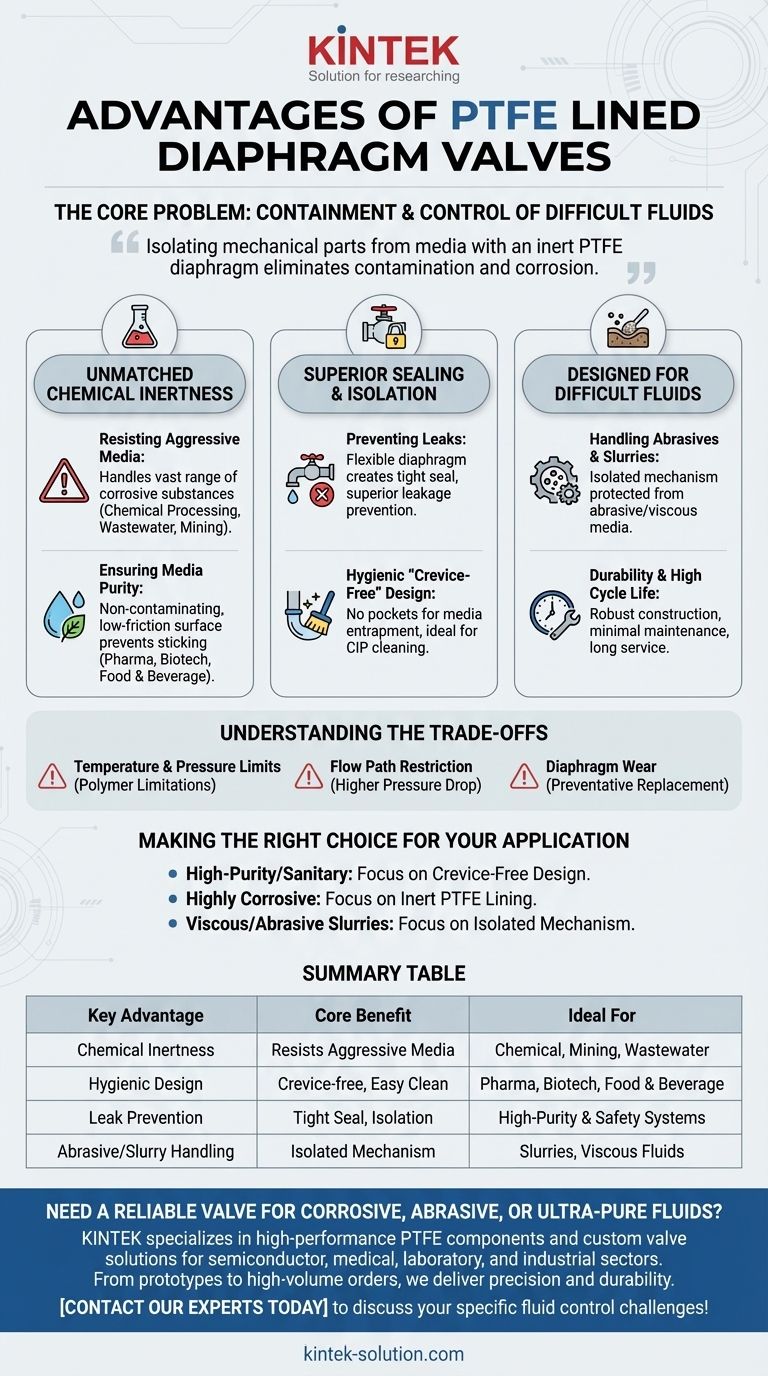

The core problem these valves solve is the reliable containment and control of difficult fluids. By isolating the valve's mechanical parts from the media with an inert PTFE diaphragm, they eliminate both contamination of the fluid and corrosion of the valve itself.

The Core Advantage: Unmatched Chemical Inertness

The primary reason to specify a PTFE lined diaphragm valve is its near-universal resistance to chemical attack. This stems directly from the properties of the Polytetrafluoroethylene (PTFE) lining.

Resisting Aggressive Media

PTFE is one of the most chemically inert polymers available. This quality allows the valve to handle a vast range of aggressive and corrosive media without degrading.

This makes them essential in industries like chemical processing, wastewater treatment, and mining, where harsh substances are common.

Ensuring Media Purity

The smooth, low-friction surface of PTFE is non-contaminating. It features low surface adhesion, which means media is less likely to stick to the valve's wetted parts.

This is a critical advantage in pharmaceutical, biotech, and food and beverage applications where preventing contamination and ensuring product purity is non-negotiable.

Superior Sealing and Process Isolation

Beyond chemical resistance, the fundamental design of a diaphragm valve provides unique benefits for process control and hygiene.

Preventing Leaks

The flexible diaphragm presses against a "weir" or seat in the valve body to create an exceptionally tight seal. This design offers superior leakage prevention compared to many other valve types, ensuring both safety and process efficiency.

The Hygienic "Crevice-Free" Design

A key feature is the valve's "no-pocket" or crevice-free internal profile. There are no cavities where media can become trapped, which is vital for preventing bacterial growth or cross-contamination between batches.

This design makes these valves ideal for systems that require frequent and thorough cleaning, such as Clean-in-Place (CIP) processes common in sanitary applications.

Designed for Difficult and Demanding Fluids

The unique operating principle of a diaphragm valve makes it uniquely suited for media that would challenge or destroy other valve designs.

Handling Abrasives and Slurries

Because the valve's operating mechanism (stem, etc.) is completely isolated from the fluid path, it is protected from abrasive or viscous media.

This allows the valve to effectively throttle or shut off slurries, crystallizing fluids, and other challenging substances without clogging or premature wear.

Durability and High Cycle Life

The robust construction and simple mechanism lead to a long service life with minimal maintenance. This reduces operational costs and downtime, providing a cost-effective solution for demanding applications over the long term.

Understanding the Trade-offs

While highly effective, PTFE lined diaphragm valves are not the solution for every scenario. Understanding their limitations is key to proper application.

Temperature and Pressure Limits

PTFE, like most polymers, has a more limited operating temperature and pressure range than all-metal valves. Exceeding these specifications can lead to diaphragm failure.

Flow Path Restriction

The weir-style design that enables the tight seal also creates a more restrictive flow path compared to full-port valves like ball or gate valves. This can result in a higher pressure drop across the valve.

Diaphragm Wear

The diaphragm is a flexible component that is subject to mechanical stress. While durable, it is a wear item that will eventually require replacement as part of a preventative maintenance schedule.

Making the Right Choice for Your Application

Selecting a PTFE lined diaphragm valve is a strategic choice for specific challenges. Your primary goal will determine if it's the right fit.

- If your primary focus is high-purity or sanitary processes: The valve's crevice-free, non-contaminating design is its most significant advantage.

- If your primary focus is handling highly corrosive chemicals: The inert PTFE lining provides safe, long-term containment where most other materials would fail.

- If your primary focus is controlling viscous or abrasive slurries: The isolated mechanism and smooth flow path prevent the clogging and wear that plague other valve types.

Ultimately, these valves provide a robust and reliable solution for the most demanding fluid handling systems.

Summary Table:

| Key Advantage | Core Benefit | Ideal For |

|---|---|---|

| Chemical Inertness | Resists aggressive & corrosive media | Chemical processing, mining, wastewater |

| Hygienic Design | Crevice-free, easy to clean, prevents contamination | Pharma, biotech, food & beverage |

| Leak Prevention | Tight seal, superior process isolation | High-purity & safety-critical systems |

| Abrasive/Slurry Handling | Isolated mechanism, no clogging | Slurries, viscous or crystallizing fluids |

Need a reliable valve for corrosive, abrasive, or ultra-pure fluids? KINTEK specializes in manufacturing high-performance PTFE components, including custom valve solutions for the semiconductor, medical, laboratory, and industrial sectors. From prototypes to high-volume orders, we deliver precision and durability. Contact our experts today to discuss your specific fluid control challenges!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What additional benefits do PTFE rotary shaft seals offer? Achieve Superior Reliability in Extreme Conditions

- Why are PTFE gaskets suitable for pharmaceutical and food equipment? Ensure Purity and FDA Compliance

- What is the difference between etched one side and pressure sensitive tape in PTFE? Choose the Right Bonding Method

- What are the key features of PTFE? Unmatched Performance for Extreme Industrial Environments

- What type of sealing is used for the ball shaft in PTFE ball valves? Discover the Maintenance-Free V-Ring System

- What are the advantages and disadvantages of etched PTFE diaphragms? Solve Critical Delamination Failures

- What are the benefits of using PTFE lined valves? Achieve Superior Reliability in Corrosive Applications

- Why are PTFE spring-energized seals preferred for dynamic sealing applications? For Superior, Long-Lasting Performance