The fundamental difference is that "etched one side" PTFE is a material prepared for bonding, while "pressure sensitive tape" is that same etched material with an adhesive already applied. One gives you the choice of adhesive, and the other offers the convenience of a ready-to-use product.

The core challenge with PTFE is its famous non-stick surface, which prevents standard glues from working. Chemical etching is the essential process that modifies one side of the PTFE, making it bondable. Your choice between an etched sheet and a pressure-sensitive tape simply comes down to whether you want to apply your own adhesive or use a pre-applied one.

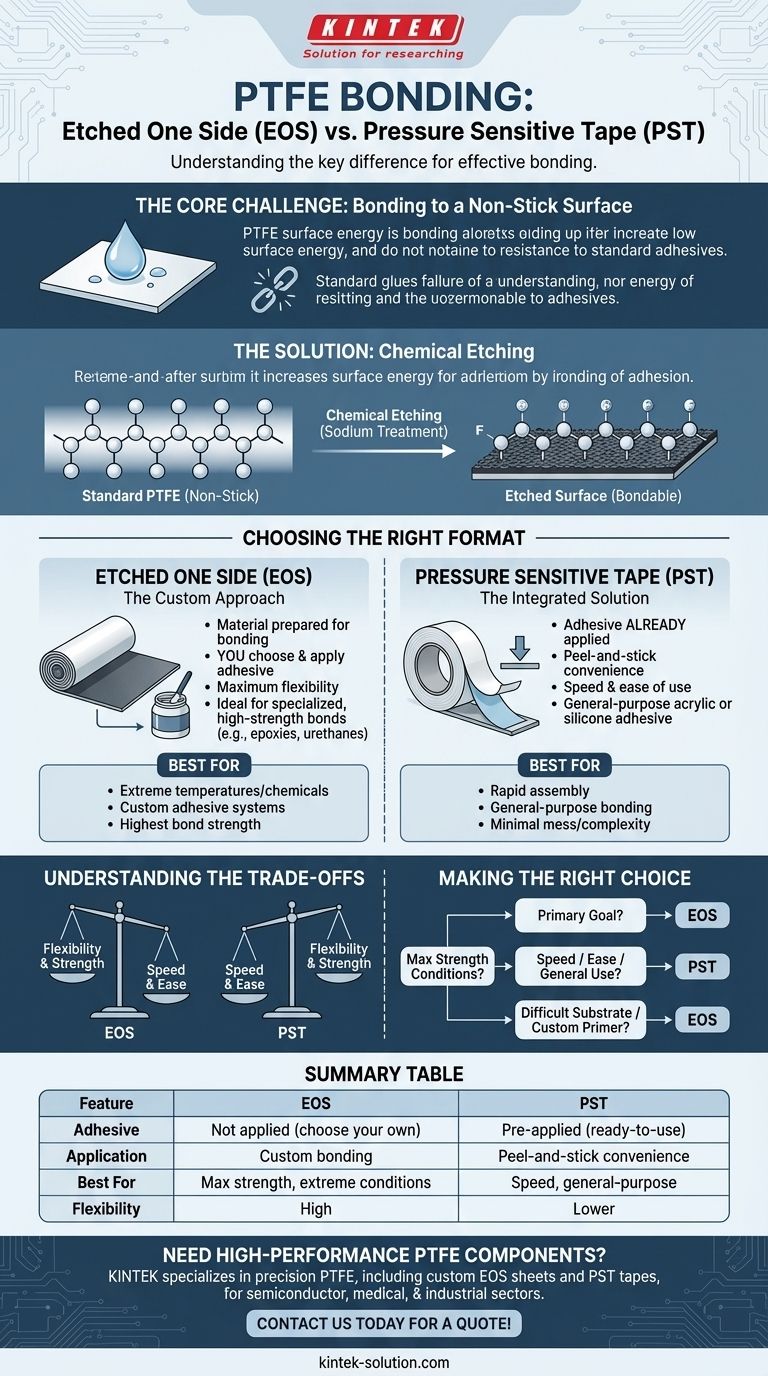

The Core Problem: Bonding to a Non-Stick Surface

PTFE (polytetrafluoroethylene) is prized for its extremely low friction and chemical inertness. These same properties make it nearly impossible for adhesives to form a mechanical or chemical bond with its surface.

The Nature of PTFE's Surface

The surface energy of standard PTFE is incredibly low. This means liquids, including liquid adhesives, bead up on the surface rather than "wetting" it out, which is a necessary first step for creating a strong bond.

Why Standard Adhesives Fail

Without the ability to wet the surface, an adhesive cannot flow into the microscopic peaks and valleys to create a physical grip. This results in an extremely weak bond that will peel away with minimal force.

The Solution: Chemical Etching

To overcome this bonding challenge, the PTFE surface must be chemically altered. This process is known as etching.

What is Etching?

Etching involves treating one side of the PTFE with a solution, typically a sodium-based compound. This process aggressively removes fluorine atoms from the polymer chains on the surface.

How Etching Enables Bonding

This removal of fluorine atoms leaves behind a carbonaceous layer. This new surface has a much higher surface energy, is visually darker (often brown or tan), and is chemically receptive to a wide range of adhesives, such as epoxies and urethanes.

Choosing the Right Format: Sheet vs. Tape

Once the PTFE is etched, it is sold in two primary formats, which directly correspond to your question.

"Etched One Side" (EOS): The Custom Approach

This is a sheet or film of PTFE where only one side has undergone the etching process. It is supplied without any adhesive.

You are responsible for selecting and applying your own adhesive. This gives you complete control to choose a specific glue (e.g., a high-temperature epoxy) that is perfectly suited for your substrate and operating environment.

"Pressure Sensitive Tape" (PST): The Integrated Solution

This product is an etched PTFE sheet that comes with an adhesive already applied to the etched side, protected by a peel-off release liner.

The pre-applied adhesive is typically a high-performance acrylic or silicone. This format is designed for convenience, speed, and ease of application—you simply peel and stick.

Understanding the Trade-offs

Choosing between these two formats involves a direct trade-off between control and convenience.

Flexibility vs. Speed

Etched One Side sheets offer maximum flexibility. You can optimize bond strength, temperature resistance, or chemical compatibility by selecting a specialized adhesive.

Pressure Sensitive Tape offers maximum speed and ease of use. It eliminates the mess and complexity of mixing and applying two-part adhesives, making it ideal for rapid assembly.

Bond Performance

The pre-applied adhesives on PST are excellent for general-purpose use. However, for the most demanding applications requiring extreme bond strength or resistance to specific chemicals, sourcing a specialized adhesive for an Etched One Side sheet will almost always yield superior results.

Application Considerations

It is your responsibility to test and validate any material for its intended use. The performance of the final bond depends not only on the PTFE format but also on the cleanliness of the substrate, application pressure, and environmental conditions.

Making the Right Choice for Your Application

Your final decision should be guided by the specific demands of your project.

- If your primary focus is maximum bond strength or resistance to extreme temperatures/chemicals: Choose an "Etched One Side" sheet and pair it with a specialized two-part epoxy or urethane adhesive.

- If your primary focus is speed, ease of use, and general-purpose bonding: Choose "Pressure Sensitive Tape" for its simple and efficient peel-and-stick application.

- If you are bonding to a difficult substrate that requires a specific primer or adhesive system: The "Etched One Side" sheet provides the necessary flexibility to use that custom system.

By understanding that etching is the key to bonding PTFE, you can confidently select the format that best aligns with your project's goals.

Summary Table:

| Feature | Etched One Side (EOS) PTFE | Pressure Sensitive Tape (PST) |

|---|---|---|

| Adhesive | Not applied (choose your own) | Pre-applied (ready-to-use) |

| Application | Custom bonding with specialized adhesives | Peel-and-stick convenience |

| Best For | Maximum strength, extreme temperatures/chemicals | Speed, ease, general-purpose bonding |

| Flexibility | High (choose adhesive for specific needs) | Lower (uses general-purpose adhesive) |

Need High-Performance PTFE Components with Custom Bonding Solutions?

KINTEK specializes in manufacturing precision PTFE components, including custom etched one-side sheets and pressure-sensitive tapes, for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, we provide the right PTFE format for your bonding requirements.

Contact us today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech