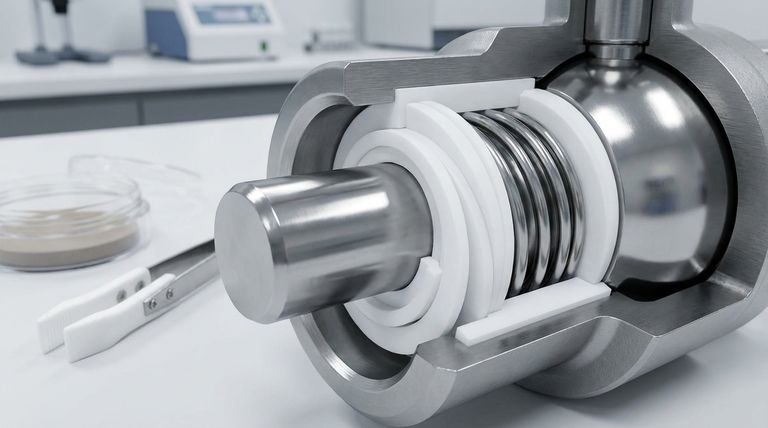

To be precise, the ball shaft in a PTFE ball valve is sealed using a maintenance-free, spring-loaded PTFE V-ring packing. This specific multi-component system is engineered to provide a durable, self-adjusting seal that prevents leaks over the valve's entire lifecycle without manual intervention.

The core takeaway is that this isn't just a simple seal; it's an engineered system. The combination of PTFE's chemical resilience, the V-ring's multi-lip design, and the constant pressure from springs creates a highly reliable seal that automatically compensates for wear and pressure changes.

Deconstructing the Sealing Mechanism

To understand why this design is so effective, we must look at its three critical components: the material (PTFE), the shape (V-ring), and the activator (the spring).

The Role of PTFE Material

Polytetrafluoroethylene (PTFE) is the foundation of the seal's performance. Its properties make it exceptionally suited for demanding industrial applications.

PTFE offers near-universal chemical resistance, making it inert to strong acids, alkalis, and other corrosive media that would degrade lesser materials.

Its extremely low coefficient of friction and self-lubricating nature prevent the seal from sticking to the rotating ball shaft, which significantly reduces wear and ensures smooth valve operation.

The V-Ring Packing Design

The seal is not a single, flat gasket. It is a V-ring packing, which consists of a stack of several nested, V-shaped rings.

This configuration creates multiple sealing points along the shaft. Each "V" acts as an independent lip seal, dramatically increasing the system's effectiveness and redundancy against leaks.

The Spring-Loaded Advantage

The "spring-loaded" feature is what makes the seal both maintenance-free and consistently reliable.

A spring mechanism applies constant, live pressure to the V-ring packing. This force ensures the seal remains engaged with the shaft at all times.

Crucially, this design automatically compensates for seal wear, thermal expansion or contraction, and pressure fluctuations, eliminating the need for periodic manual tightening.

Understanding the Trade-offs

While this sealing system is robust, understanding its operational limits is critical for proper application.

Temperature Limitations

PTFE has a distinct upper temperature limit, typically around 250°C (482°F). Exceeding this can cause the material to deform or degrade, compromising the seal's integrity.

Potential for Cold Flow

Under high, sustained pressure, PTFE can exhibit a phenomenon known as "creep" or cold flow, where the material slowly deforms. The spring-loaded design is specifically engineered to counteract this tendency by maintaining constant pressure on the packing.

Making the Right Choice for Your Application

This sealing technology is chosen for its specific performance characteristics. Evaluating it against your primary needs ensures optimal valve selection.

- If your primary focus is chemical compatibility: The use of PTFE provides an elite level of resistance against nearly all corrosive process media.

- If your primary focus is long-term reliability: The spring-loaded V-ring design ensures a consistent, self-adjusting seal that compensates for wear and system changes.

- If your primary focus is minimizing maintenance: This system is explicitly designed to be "maintenance-free," reducing operational costs and downtime.

Ultimately, this advanced sealing system is engineered to provide confidence in the valve's ability to perform reliably in the most demanding environments.

Summary Table:

| Component | Function | Benefit |

|---|---|---|

| PTFE Material | Provides chemical resistance and low friction. | Handles corrosive media, reduces wear. |

| V-Ring Design | Creates multiple sealing lips along the shaft. | Enhances leak prevention and redundancy. |

| Spring Mechanism | Applies constant pressure to the packing. | Automatically compensates for wear and system changes. |

Need a reliable sealing solution for your critical applications?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a sealing system that delivers unmatched chemical resistance, durability, and maintenance-free performance.

Contact us today to discuss your specific requirements and let our experts provide a tailored solution for your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts