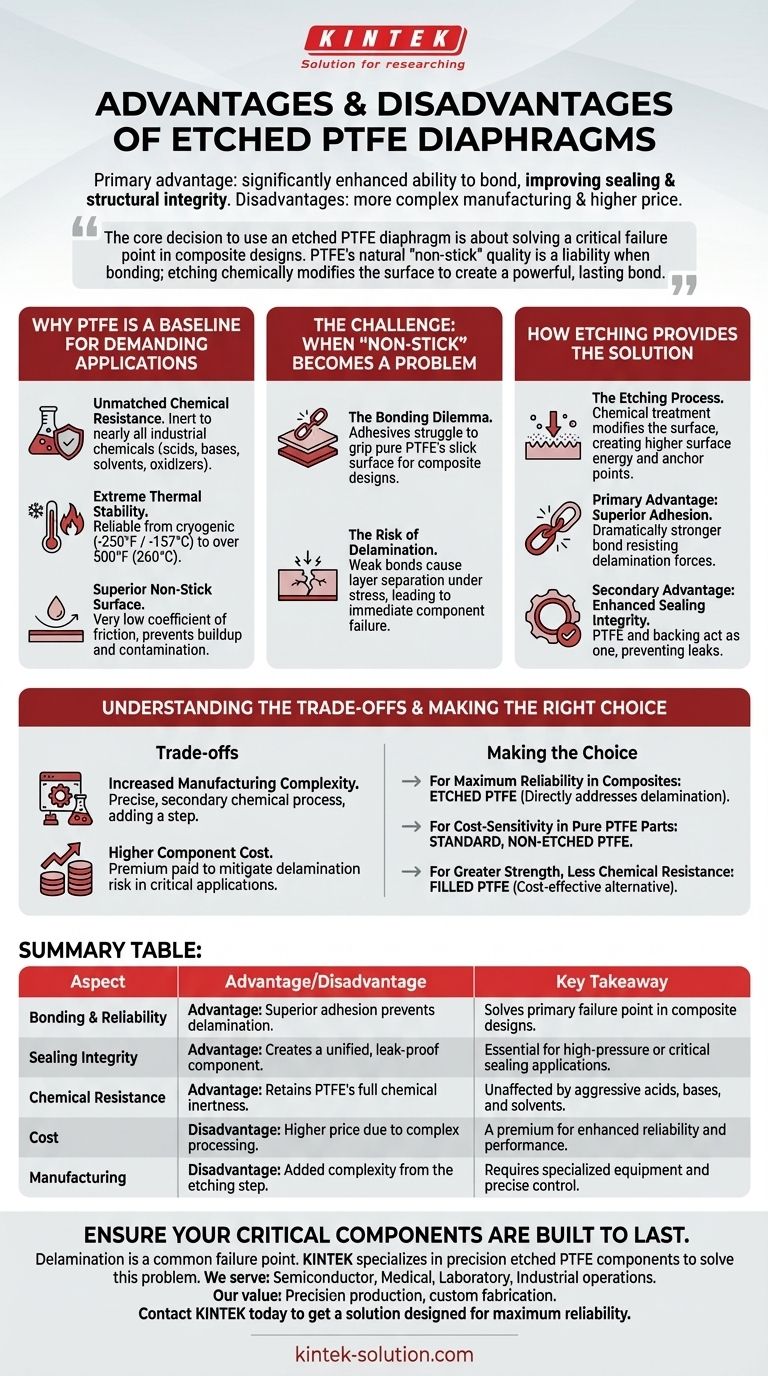

The primary advantage of an etched PTFE diaphragm is its significantly enhanced ability to bond to other materials, which improves sealing and structural integrity. This benefit comes at the cost of a more complex manufacturing process and, consequently, a higher price point compared to its non-etched counterparts.

The core decision to use an etched PTFE diaphragm is not about the PTFE itself, but about solving a critical failure point in composite designs. PTFE's natural "non-stick" quality is a liability when bonding is required; etching chemically modifies the surface to create a powerful, lasting bond where one would otherwise fail.

Why PTFE is a Baseline for Demanding Applications

Before analyzing the etching process, it's crucial to understand why Polytetrafluoroethylene (PTFE) is a material of choice for critical components like diaphragms. Its inherent properties provide a level of performance that few other materials can match.

Unmatched Chemical Resistance

PTFE is famously inert. It remains stable when exposed to nearly all industrial chemicals, including aggressive acids, bases, solvents, and oxidizers. This ensures the diaphragm will not degrade or contaminate the process media.

Extreme Thermal Stability

The material performs reliably across an exceptionally wide temperature range, from cryogenic conditions (-250°F / -157°C) up to over 500°F (260°C). This makes it suitable for processes involving extreme temperature fluctuations.

Superior Non-Stick Surface

PTFE's very low coefficient of friction prevents material buildup and contamination. In a diaphragm, this ensures smooth, consistent flex life and prevents media from adhering to the surface.

The Challenge: When "Non-Stick" Becomes a Problem

While PTFE's properties are exceptional, its low surface energy—the very thing that makes it non-stick—creates a significant engineering challenge.

The Bonding Dilemma

In many applications, a PTFE diaphragm is bonded to a rubber backing (like EPDM or Viton) to add strength and flexibility. Adhesives struggle to grip pure PTFE's slick surface, making a durable bond extremely difficult to achieve.

The Risk of Delamination

A weak bond between the PTFE layer and its rubber backing is a primary point of failure. Under the mechanical stress of repeated flexing, pressure changes, or thermal cycling, the layers can separate, an event known as delamination, leading to immediate component failure.

How Etching Provides the Solution

Etching is a chemical surface treatment designed specifically to overcome PTFE's natural resistance to bonding.

The Etching Process

The process involves exposing one side of the PTFE diaphragm to a chemical agent that reacts with the fluorine molecules on the surface. This reaction microscopically roughens the surface, creating a new chemical structure with vastly higher surface energy.

Primary Advantage: Superior Adhesion

This chemically altered surface provides microscopic anchor points for adhesives and elastomers to grip. The result is a dramatically stronger and more reliable bond that resists the forces that cause delamination.

Secondary Advantage: Enhanced Sealing Integrity

By ensuring the PTFE and backing material act as a single, unified component, etching enhances the overall integrity of the seal. This prevents leaks that could occur if the layers were to shift or separate even slightly.

Understanding the Trade-offs

Opting for an etched PTFE diaphragm is not a universal solution. It involves clear trade-offs that must be weighed against the application's requirements.

Increased Manufacturing Complexity

Etching is a precise, secondary chemical process that adds a significant step to production. It requires specialized equipment and handling procedures to ensure consistent and effective surface treatment.

Higher Component Cost

The additional manufacturing step, specialized chemicals, and quality control associated with etching invariably increase the final cost of the diaphragm. This premium is paid to mitigate the risk of delamination failure in critical applications.

Making the Right Choice for Your Application

Your final decision should be guided by the specific operational demands and failure risks of your system.

- If your primary focus is maximum reliability in a composite diaphragm: Etched PTFE is the correct choice, as it directly addresses the most common failure mode—delamination.

- If your primary focus is cost-sensitivity for a non-bonded, pure PTFE part: A standard, non-etched diaphragm provides all the inherent benefits of PTFE without the added cost.

- If you require greater mechanical strength than PTFE but can tolerate less chemical resistance: A filled PTFE diaphragm might be a more cost-effective alternative to a composite design.

Ultimately, choosing an etched PTFE diaphragm is a strategic investment in long-term operational integrity and failure prevention.

Summary Table:

| Aspect | Advantage/Disadvantage | Key Takeaway |

|---|---|---|

| Bonding & Reliability | Advantage: Superior adhesion prevents delamination. | Solves the primary failure point in composite designs. |

| Sealing Integrity | Advantage: Creates a unified, leak-proof component. | Essential for high-pressure or critical sealing applications. |

| Chemical Resistance | Advantage: Retains PTFE's full chemical inertness. | Unaffected by aggressive acids, bases, and solvents. |

| Cost | Disadvantage: Higher price due to complex processing. | A premium for enhanced reliability and performance. |

| Manufacturing | Disadvantage: Added complexity from the etching step. | Requires specialized equipment and precise control. |

Ensure your critical components are built to last.

Delamination is a common and costly failure point in PTFE composite diaphragms. At KINTEK, we specialize in manufacturing precision PTFE components, including custom etched diaphragms, to solve this exact problem. Our etching process ensures a powerful, lasting bond that withstands extreme chemical, thermal, and mechanical stress.

We serve:

- Semiconductor manufacturers requiring ultra-pure, reliable components.

- Medical and Laboratory equipment makers needing contamination-free performance.

- Industrial operations where downtime from component failure is not an option.

Our value to you: We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring you get a component perfectly tailored to your application's demands.

Don't let a weak bond compromise your system's integrity. Contact KINTEK today to discuss your specific requirements and get a solution designed for maximum reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability