At its core, PTFE gaskets are exceptionally suitable for pharmaceutical and food applications because of their fundamental chemical inertness. This single property means they are non-toxic, do not react with or contaminate products, and prevent the buildup of materials, ensuring the highest levels of purity and safety required by regulatory bodies like the FDA.

The suitability of PTFE is not just about meeting a checklist of requirements; it's about its inherent molecular stability. Because it is one of the most non-reactive substances known, it provides a trustworthy barrier that protects product integrity in sensitive environments.

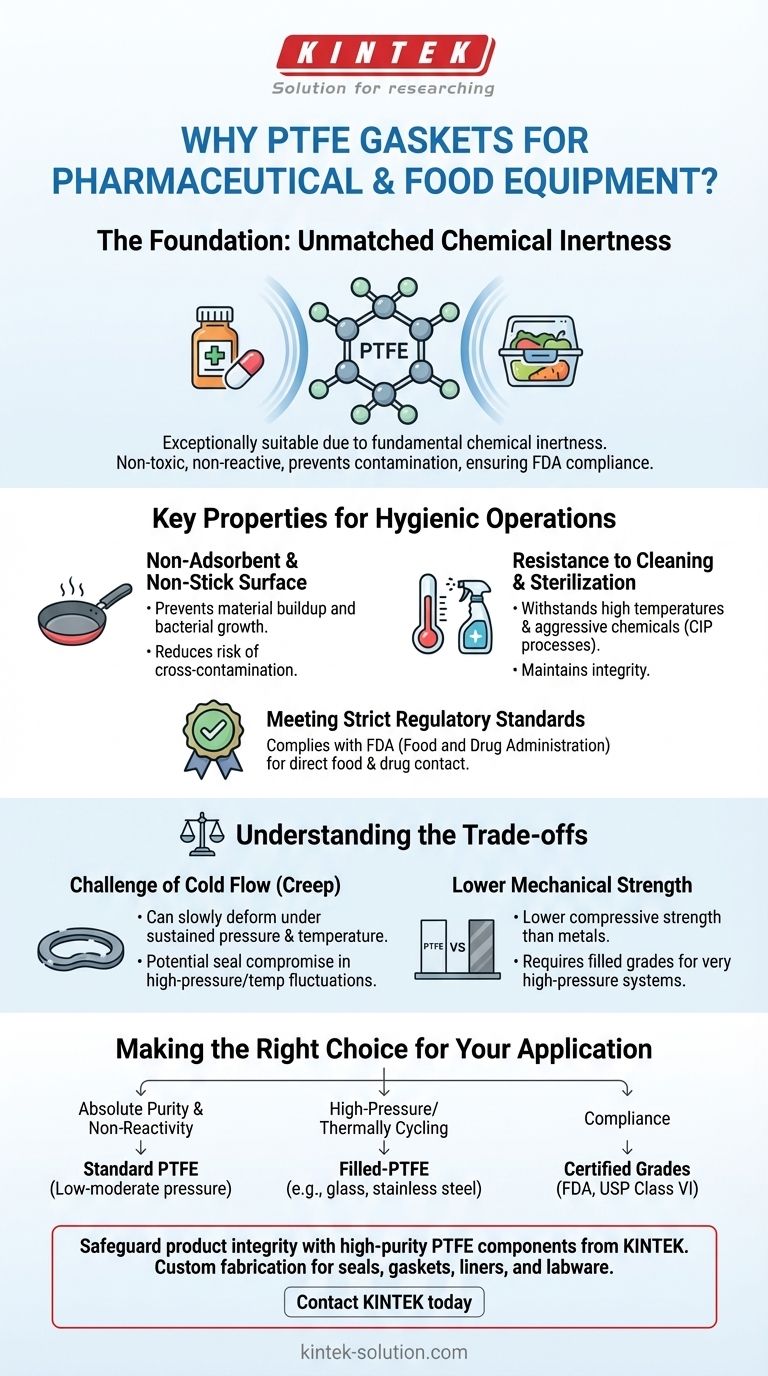

The Foundation: Unmatched Chemical Inertness

The primary reason PTFE (polytetrafluoroethylene) is a default choice in sanitary applications is its non-reactive nature. This characteristic is the source of nearly all its other safety benefits.

Preventing Contamination and Leaching

A material that is chemically inert will not break down or release particles when it comes into contact with other substances. This is critical in food and pharma.

PTFE gaskets do not leach chemicals into the product stream, ensuring that the final product—whether a medicine or a food item—remains pure and unadulterated.

Ensuring Product Purity

Because it doesn't react with its environment, PTFE is inherently non-toxic, odorless, and tasteless.

This guarantees that the gasket will not impart any unwanted characteristics to the product, preserving its intended formulation, flavor, and safety profile.

Key Properties for Hygienic Operations

Beyond its inertness, PTFE's physical properties make it ideal for the demanding operational conditions found in food and pharmaceutical processing plants.

Non-Adsorbent and Non-Stick Surface

PTFE is famous for its non-stick surface. In a processing environment, this means materials do not adhere to the gasket.

This property is crucial for preventing material buildup, which can harbor bacteria and lead to cross-contamination between different production batches.

Resistance to Cleaning and Sterilization

Sanitary equipment must undergo rigorous cleaning and sterilization, often involving high temperatures and aggressive chemicals (Clean-in-Place/CIP processes).

PTFE can withstand a wide range of temperatures and is resistant to virtually all industrial chemicals, ensuring it maintains its integrity and sealing capability through repeated cleaning cycles.

Meeting Strict Regulatory Standards

Materials used in these industries are not chosen lightly; they must comply with government and industry regulations.

PTFE is widely recognized for meeting stringent standards, including those set by the FDA (Food and Drug Administration) for materials in direct contact with food and drugs.

Understanding the Trade-offs

While PTFE is an excellent material, no solution is perfect. A true technical understanding requires acknowledging its limitations.

The Challenge of Cold Flow (Creep)

The primary drawback of virgin PTFE is its tendency to "creep" or "cold flow." Under sustained pressure and temperature, the material can slowly deform.

This deformation can cause the gasket to loosen over time, potentially compromising the seal. This is a critical factor to consider in applications with high pressures or significant temperature fluctuations.

Lower Mechanical Strength

Compared to metals or some other polymers, PTFE has lower compressive strength.

In extremely high-pressure systems, a pure PTFE gasket may not be sufficient. In these cases, filled or reinforced PTFE grades are often used to enhance mechanical properties while retaining chemical inertness.

Making the Right Choice for Your Application

Selecting the right gasket material requires balancing the need for purity with the mechanical demands of the system.

- If your primary focus is absolute purity and non-reactivity: Standard PTFE is often the best and simplest choice for low-to-moderate pressure applications.

- If your primary focus is maintaining a seal in a high-pressure or thermally cycling system: Investigate filled-PTFE options (e.g., glass-filled or stainless steel-filled) to mitigate cold flow and improve mechanical stability.

- If your primary focus is compliance: Always ensure the specific grade of PTFE you select is certified to meet the required standards for your industry, such as FDA or USP Class VI.

Ultimately, PTFE's value comes from providing a chemically invisible barrier that safeguards the integrity of your process and the safety of your final product.

Summary Table:

| Key Property | Benefit for Pharma & Food Applications |

|---|---|

| Chemical Inertness | Non-reactive, prevents contamination and leaching, ensures product purity. |

| Non-Stick Surface | Prevents material buildup, reduces risk of bacterial growth and cross-contamination. |

| High-Temp & Chemical Resistance | Withstands rigorous cleaning/sterilization (CIP) processes. |

| FDA Compliance | Meets stringent regulatory standards for safety. |

Safeguard your product integrity with high-purity PTFE components from KINTEK.

For pharmaceutical, medical, laboratory, and food processing industries, product purity and regulatory compliance are non-negotiable. KINTEK specializes in manufacturing precision PTFE components—including seals, gaskets, liners, and labware—that deliver the chemical inertness and performance reliability your applications demand.

We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit for your equipment and processes.

Contact KINTEK today to discuss your specific requirements and receive a quote for PTFE solutions you can trust.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability