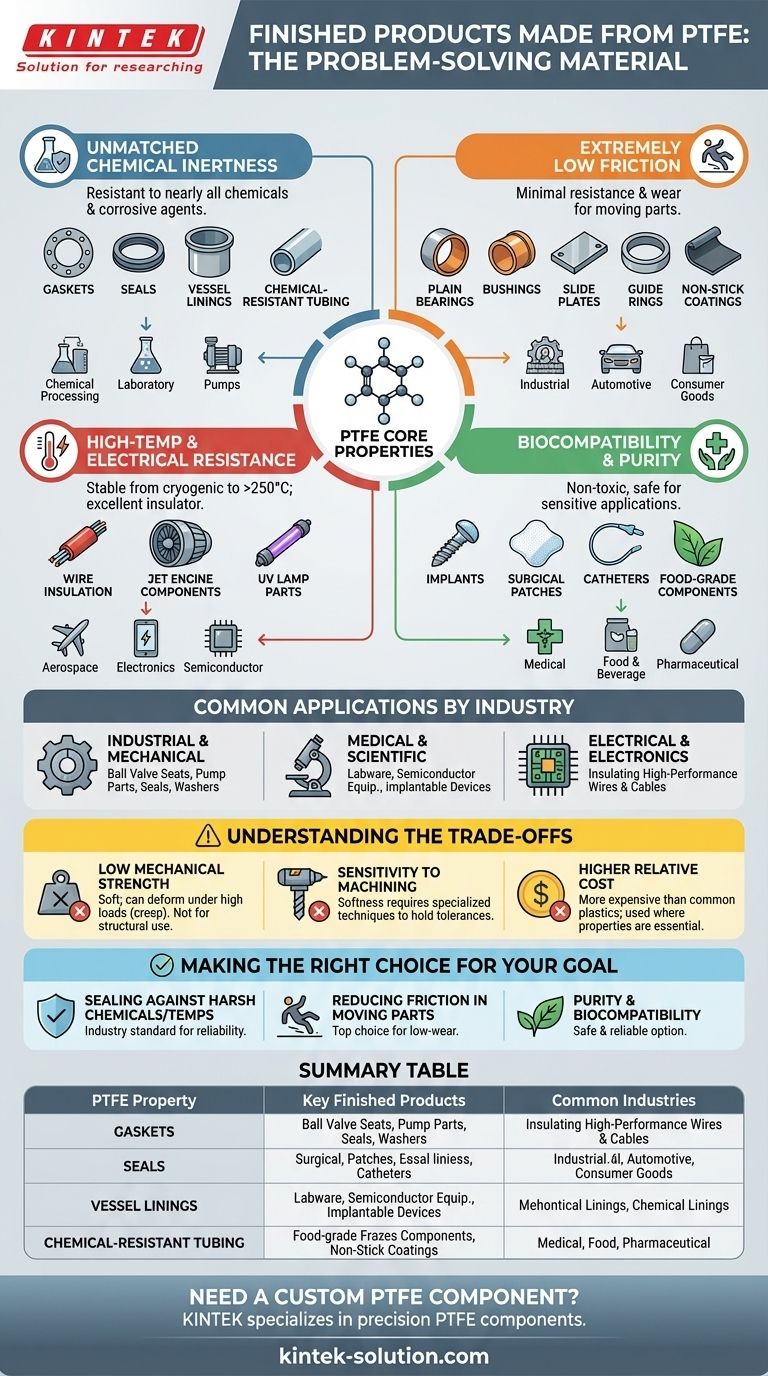

In short, Polytetrafluoroethylene (PTFE) is used to manufacture a vast range of finished products, most notably high-performance seals, gaskets, rings, bearings, and bushings. Its unique properties also make it essential for creating chemically resistant labware, electrical insulators, medical implants, non-stick coatings, and critical components for the chemical, food, and semiconductor industries.

The key takeaway is not the long list of products, but the reason behind it: PTFE is a problem-solving material. Its applications are dictated by its three core properties—near-total chemical inertness, an extremely low coefficient of friction, and high-temperature resistance—making it the default choice for components that must perform in harsh environments where other materials would fail.

Why PTFE is So Versatile: The Core Properties

The value of PTFE comes from a unique combination of characteristics that are difficult to find in any other single polymer. Understanding these properties explains why its applications are so diverse.

Unmatched Chemical Inertness

PTFE is resistant to nearly all chemicals, solvents, and corrosive agents. This makes it an invaluable material for any application involving aggressive substances.

Finished products derived from this property include gaskets, seals, vessel linings, and chemical-resistant tubing. These components ensure system integrity in chemical processing plants, laboratories, and pumps.

Extremely Low Friction

Often cited as one of the most slippery materials in existence, PTFE has an exceptionally low coefficient of friction. This allows moving parts to operate with minimal resistance and wear.

This property is the reason PTFE is used for plain bearings, bushings, slide plates, and guide rings. It is also the principle behind its most famous consumer application: non-stick coatings for cookware.

High-Temperature and Electrical Resistance

PTFE maintains its stability and integrity across a wide temperature range, from cryogenic conditions to over 250°C (500°F). It is also an excellent electrical insulator.

This makes it ideal for high-performance electrical wire insulation, components in high-temperature equipment like jet engines, and parts for scientific apparatus like UV lamps.

Biocompatibility and Purity

PTFE is non-toxic and biocompatible, meaning it does not react with biological tissue. This, combined with its purity, makes it safe for sensitive applications.

In the medical field, it is used for implants, surgical patches, and components like catheters. In the food and beverage industry, it’s used for conveyor belts, manifolds, and other parts that require food-grade purity.

Common Applications by Industry

While the properties dictate the function, it's often useful to see where these products are deployed. PTFE is a critical material in nearly every advanced industry.

Industrial and Mechanical Engineering

This is PTFE's largest market. It is the backbone of fluid handling and mechanical systems, with products like ball valve seats, pump parts, seals, and washers being standard components.

Medical and Scientific

The material's inertness and biocompatibility are critical for scientific and medical devices. You will find it in labware, semiconductor equipment, and a wide array of implantable devices.

Electrical and Electronics

As a superior insulator with high thermal stability, PTFE is used for insulating high-performance wires and cables, especially in aerospace and computing where reliability is non-negotiable.

Understanding the Trade-offs

No material is perfect, and objectivity requires acknowledging a material's limitations. PTFE's unique strengths come with specific weaknesses.

Low Mechanical Strength

PTFE is a relatively soft material. It is not suitable for structural applications and can deform under high loads, a phenomenon known as "creep." This is why it is often used as a liner or coating rather than a standalone structural part.

Sensitivity to Machining

While machined PTFE parts can hold tight tolerances, the material's softness requires specialized techniques. It can be more challenging to machine than harder plastics or metals.

Higher Relative Cost

PTFE is a high-performance polymer, and its cost reflects that. It is more expensive than common plastics like polyethylene or polypropylene, so its use is typically reserved for applications where its specific properties are essential.

Making the Right Choice for Your Goal

Selecting PTFE is a decision driven by the operational demands of the finished product. Your primary goal will determine if it is the correct choice.

- If your primary focus is sealing against harsh chemicals or extreme temperatures: PTFE is an industry standard for gaskets, seals, rings, and linings where reliability is critical.

- If your primary focus is reducing friction in moving parts: Its low-friction surface makes it a top choice for bearings, bushings, and low-wear slide plates.

- If your primary focus is purity and biocompatibility: The material's inertness makes it a safe and reliable option for medical implants, food processing equipment, and semiconductor components.

Ultimately, PTFE is the material of choice when you need a component to survive and perform in an environment that would destroy lesser materials.

Summary Table:

| PTFE Property | Key Finished Products | Common Industries |

|---|---|---|

| Chemical Inertness | Seals, Gaskets, Vessel Linings, Tubing | Chemical Processing, Laboratory |

| Low Friction | Bearings, Bushings, Slide Plates, Non-stick Coatings | Industrial, Automotive, Consumer Goods |

| High-Temp & Electrical Resistance | Wire Insulation, Jet Engine Components, UV Lamp Parts | Aerospace, Electronics, Semiconductor |

| Biocompatibility & Purity | Medical Implants, Surgical Patches, Food-Grade Components | Medical, Food & Beverage, Pharmaceutical |

Need a custom PTFE component that can withstand harsh environments? KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders, ensuring your parts meet exact specifications for chemical resistance, low friction, and thermal stability. Contact us today to discuss your project requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- How does the low friction property of PTFE benefit industrial applications? Boost Efficiency & Durability

- What is PTFE commonly known as and what type of material is it? A Guide to High-Performance PTFE Properties

- How does PTFE function as an electrical insulator? Discover Its Superior Dielectric Properties

- What is the tensile strength range of PTFE? Understanding Its Mechanical Limits for Your Design

- Is PTFE safe for use in electrical environments? Achieve Superior Insulation & Reliability

- What are the advantages and disadvantages of filled PTFE? An Engineering Trade-Off Guide

- What is the electrical insulation capability of PTFE? Unmatched Reliability for Demanding Applications

- What are some consumer product applications of PTFE? Discover its Versatility Beyond Non-Stick Pans