Yes, Polytetrafluoroethylene (PTFE) is exceptionally safe and widely trusted for use in electrical environments. Its safety is a direct result of its outstanding electrical insulation properties, combined with a remarkable resistance to high temperatures, chemical exposure, and environmental degradation. This unique combination ensures reliable and stable performance under demanding conditions.

The safety of PTFE in electrical systems stems not just from its inability to conduct electricity, but from its remarkable stability. It maintains its insulating properties consistently across wide temperature ranges and harsh chemical exposures, preventing failure where other materials might degrade.

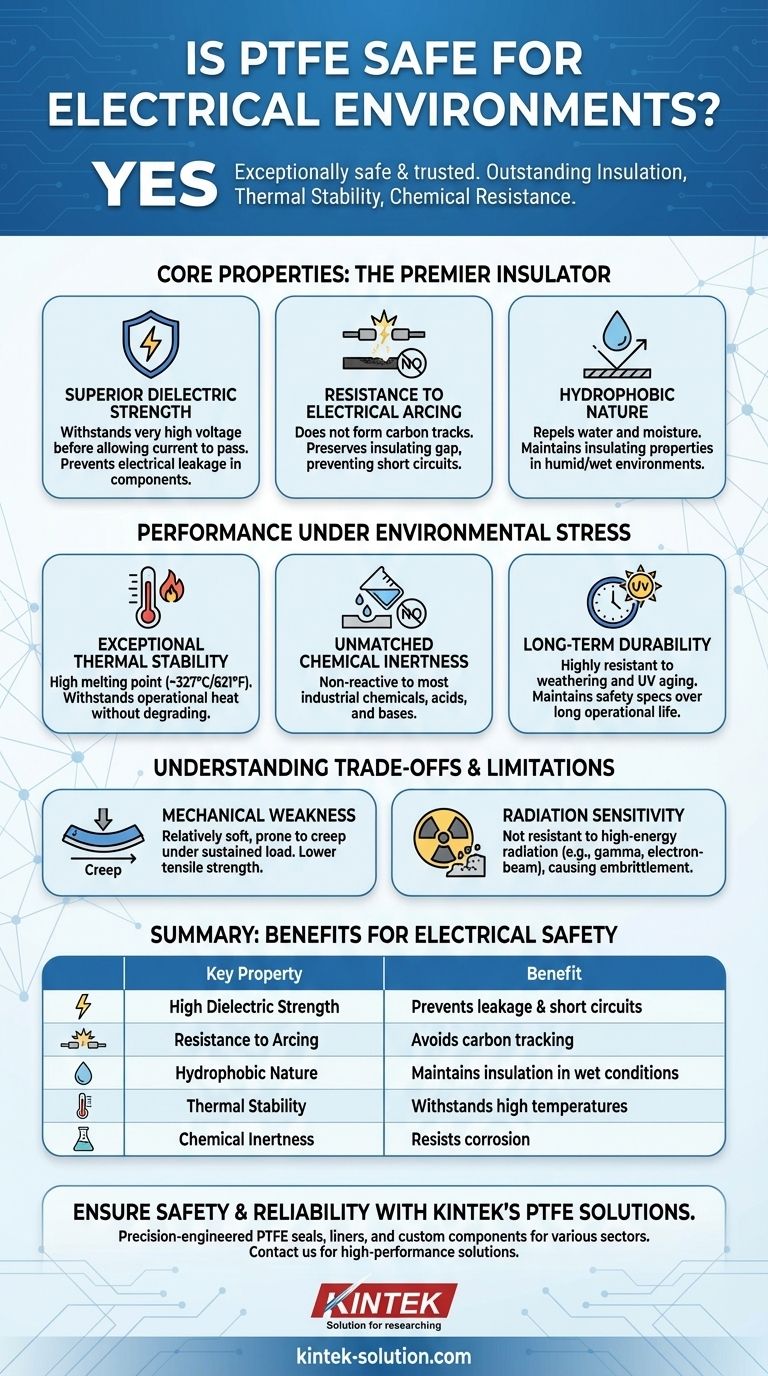

The Core Properties of PTFE as an Insulator

To understand PTFE's role in electrical safety, we must look at the specific characteristics that make it a premier insulating material. These properties work together to prevent electrical leakage, short circuits, and material failure.

Superior Dielectric Strength

PTFE is an excellent electrical insulator with a high dielectric strength. This means it can withstand a very high voltage before it allows an electrical current to pass through it.

This property is crucial for preventing electrical leakage in components like wire insulation, gaskets, and connectors, ensuring both safety and signal integrity in electronic devices.

Resistance to Electrical Arcing

When subjected to a high-voltage electrical arc, many plastics degrade and form a conductive carbon track, creating a permanent path for current that leads to catastrophic failure.

PTFE resists this process. It does not form carbon tracks when arcing occurs, a critical safety feature that preserves the insulating gap and prevents short circuits in high-voltage equipment.

Hydrophobic Nature

PTFE is hydrophobic, meaning it repels water and resists moisture absorption. Water does not "wet" its surface.

In electrical applications, this is vital. Moisture can create a conductive path on the surface of an insulator, leading to short circuits. PTFE's water-repellent nature ensures its insulating properties remain intact even in humid or wet environments.

Performance Under Environmental Stress

An insulator's reliability depends on its ability to perform consistently over time, especially when exposed to heat, chemicals, and weathering. This is where PTFE's durability becomes a key safety factor.

Exceptional Thermal Stability

PTFE has a very high melting point of around 327°C (621°F) and maintains its integrity over a wide range of service temperatures.

Electrical components often generate significant heat during operation. PTFE's ability to withstand this heat without melting, deforming, or degrading ensures that the insulation remains physically and electrically stable.

Unmatched Chemical Inertness

PTFE is non-reactive to nearly all industrial chemicals, acids, and bases.

In environments like chemical processing plants or industrial facilities, electrical components may be exposed to corrosive substances. PTFE's inertness guarantees that the insulation will not be compromised by chemical attack, preserving its safety and function.

Long-Term Durability

PTFE is highly resistant to weathering and aging from UV exposure. Its properties do not significantly degrade over long periods of service.

This long-term stability means that components insulated with PTFE will maintain their safety specifications throughout their operational life, reducing the risk of age-related failure.

Understanding the Trade-offs and Limitations

While PTFE is an outstanding electrical insulator, no material is perfect for every situation. Acknowledging its limitations is key to using it safely and effectively.

Mechanical Weakness

PTFE is a relatively soft material and can be prone to "creep," which is deformation under a sustained load. It has lower tensile strength and abrasion resistance compared to many engineering plastics.

This must be considered in applications where the component is also serving a structural or high-load-bearing purpose, as it could deform over time.

Radiation Sensitivity

PTFE does not have good resistance to high-energy radiation, such as gamma or electron-beam radiation. Exposure can cause the material's molecular structure to break down, leading to embrittlement and a loss of its beneficial properties.

For this reason, it is generally not a suitable choice for applications in high-radiation environments like nuclear facilities or certain space applications without proper shielding.

Making the Right Choice for Your Application

Selecting the correct material requires matching its properties to the primary demands of your project.

- If your primary focus is high-voltage insulation: PTFE is an elite choice due to its high dielectric strength and critical resistance to carbon tracking during arcing.

- If your primary focus is reliability in harsh environments: PTFE's unparalleled thermal stability and chemical inertness make it ideal for industrial, chemical, or high-temperature applications.

- If your primary focus is a load-bearing structural component: You should evaluate whether pure PTFE's mechanical properties are sufficient or if a filled grade of PTFE or an alternative polymer is more appropriate.

By understanding these distinct properties, you can confidently specify PTFE as a premier material for ensuring electrical safety and long-term reliability in your design.

Summary Table:

| Key Property | Benefit for Electrical Safety |

|---|---|

| High Dielectric Strength | Prevents electrical leakage and short circuits |

| Resistance to Arcing | Avoids carbon tracking in high-voltage applications |

| Hydrophobic Nature | Maintains insulation in humid or wet conditions |

| Thermal Stability | Withstands high temperatures (up to 327°C) without degrading |

| Chemical Inertness | Resists corrosion from acids, bases, and industrial chemicals |

Ensure the safety and reliability of your electrical components with KINTEK’s precision-engineered PTFE solutions. We specialize in manufacturing high-performance PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. From prototypes to high-volume orders, our custom fabrication ensures your designs meet exact specifications for dielectric strength, thermal stability, and chemical resistance. Contact us today to discuss how our PTFE expertise can enhance your application’s performance and longevity!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability